Method for preparing large-scale titanium and titanium alloy metallographic samples

A technology for metallographic samples and titanium alloys, which is applied in the field of metallographic sample preparation of titanium and titanium alloys, and achieves the effects of high magnification and clear structure, solving preparation difficulties and complete grain boundaries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The method for preparing large-scale titanium and titanium alloy metallographic samples includes the steps of sampling, grinding, polishing, cleaning, corrosion, drying and structure observation.

[0027] Sampling is to use a sawing machine to cut a 10-20mm titanium or titanium alloy thin slice sample;

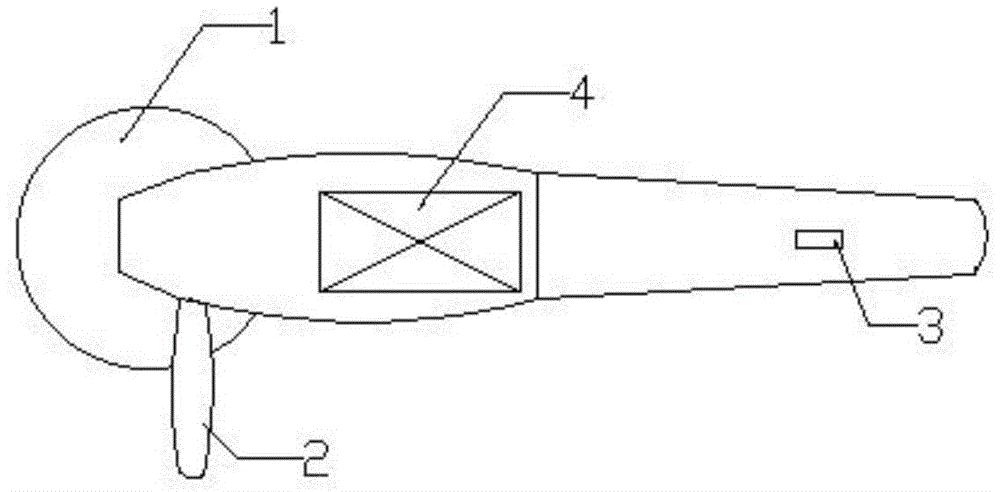

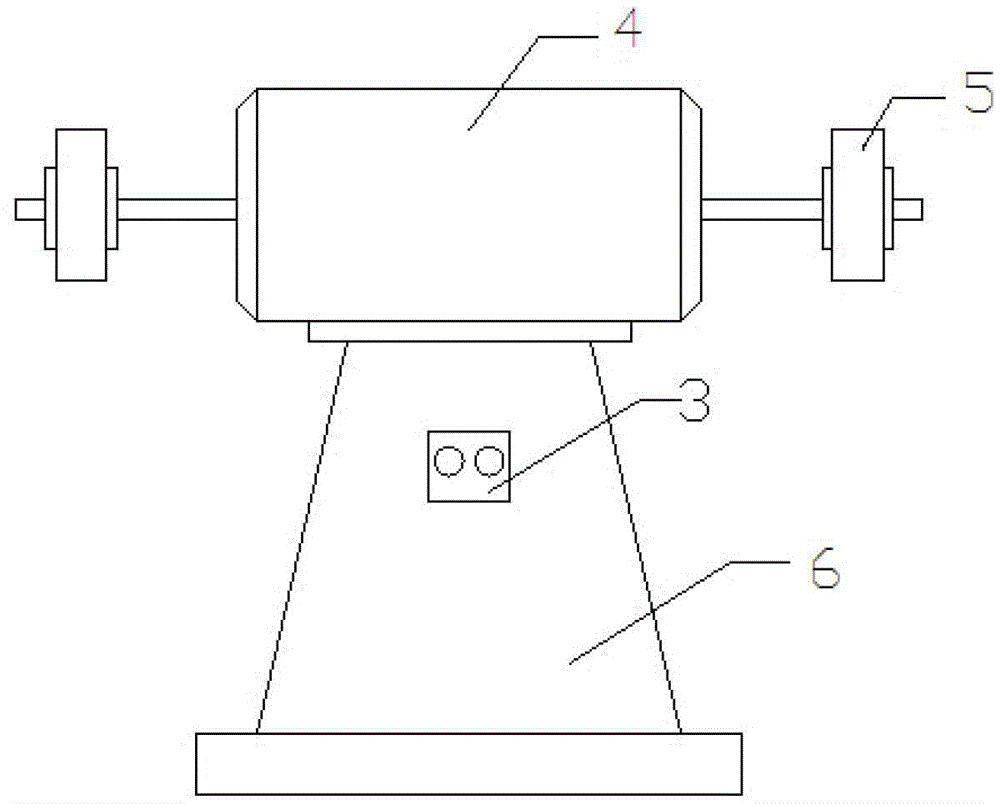

[0028] Polishing is to fix the sawed sample and use a hand-held angle grinder to polish its surface; specifically, fix the sawed sample and use an angle grinder to grind its surface until it is removed. The damage layer caused by sawing; the angle grinder includes a body and a grinding wheel arranged on the body, and the body is also provided with a handle, a motor and a switch. The grinding wheel is a PVA wheel. The advantages of PVA wheels are: PVA is a self-consumable material, which will not damage the metal substrate during the grinding process; the heat generated during the grinding process is small, and will not cause tissue changes on the surface of the sample ...

Embodiment 1

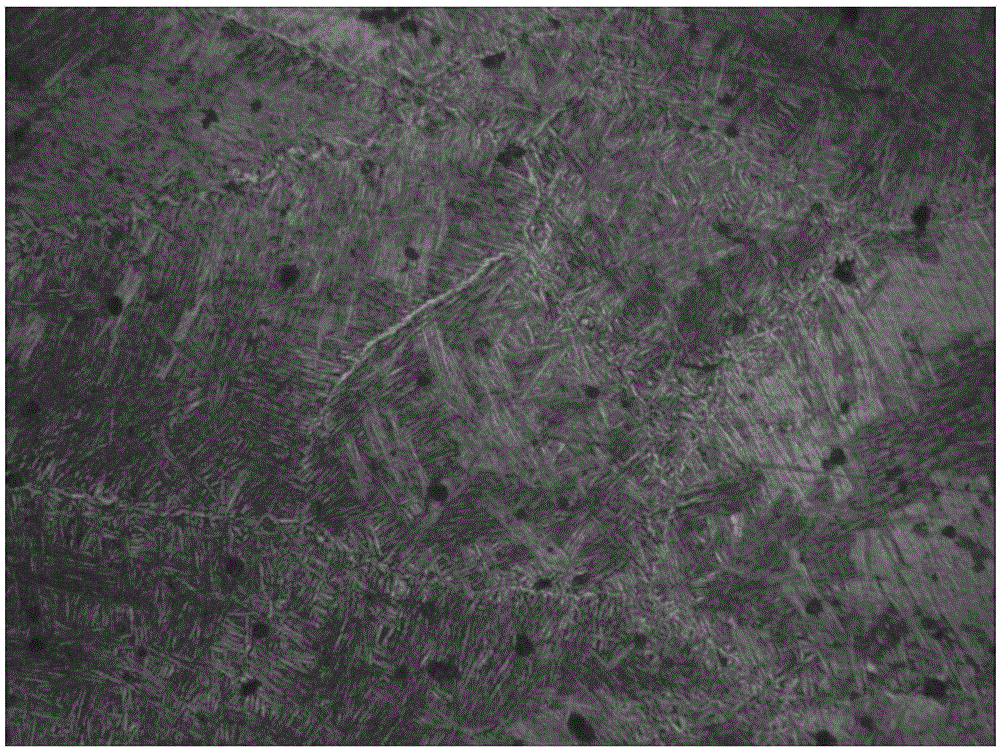

[0040] For the TC4 titanium alloy □120mm square material that has been forged twice, use a sawing machine to cut a 10-20mm thin slice sample, and polish the sawed sample with an angle grinder (installed with a PVA polishing wheel) until it is removed. The damaged layer caused by sawing; then use a vertical polishing machine to perform mechanical polishing until the surface is bright and close to the mirror surface; then the surface is cleaned, corroded, and dried. At this time, the low-magnification metallographic structure of the sample can be observed; the clear high-magnification microstructure can be observed using a metallographic microscope, such as image 3 (100х), Figure 4 (200х), typical Widmanite structure.

Embodiment 2

[0042] The TC4 titanium alloy Φ120mm round bar that has been piered three times is cut into 10-20mm thin slices with a sawing machine, and the sawed sample is polished with an angle grinder (installed with a PVA polishing wheel) until the sawing is removed. The damaged layer; then use a vertical polishing machine to perform mechanical polishing until the surface is bright and close to the mirror surface; then the surface is cleaned, corroded, and dried. At this time, the low-magnification metallographic structure of the sample can be observed; the clear high-magnification microstructure can be observed using a metallographic microscope, such as Figure 5 (100х), Image 6 As shown in (200х), it is an equiaxed α+β processed structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com