Plant row drill

A technology of row strips and racks, applied in the field of row drills, can solve the problems of not being able to adapt to agronomic requirements and breeding modes, restricting the accuracy of breeding experiments, restricting the development of the breeding industry, etc. Uniform, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

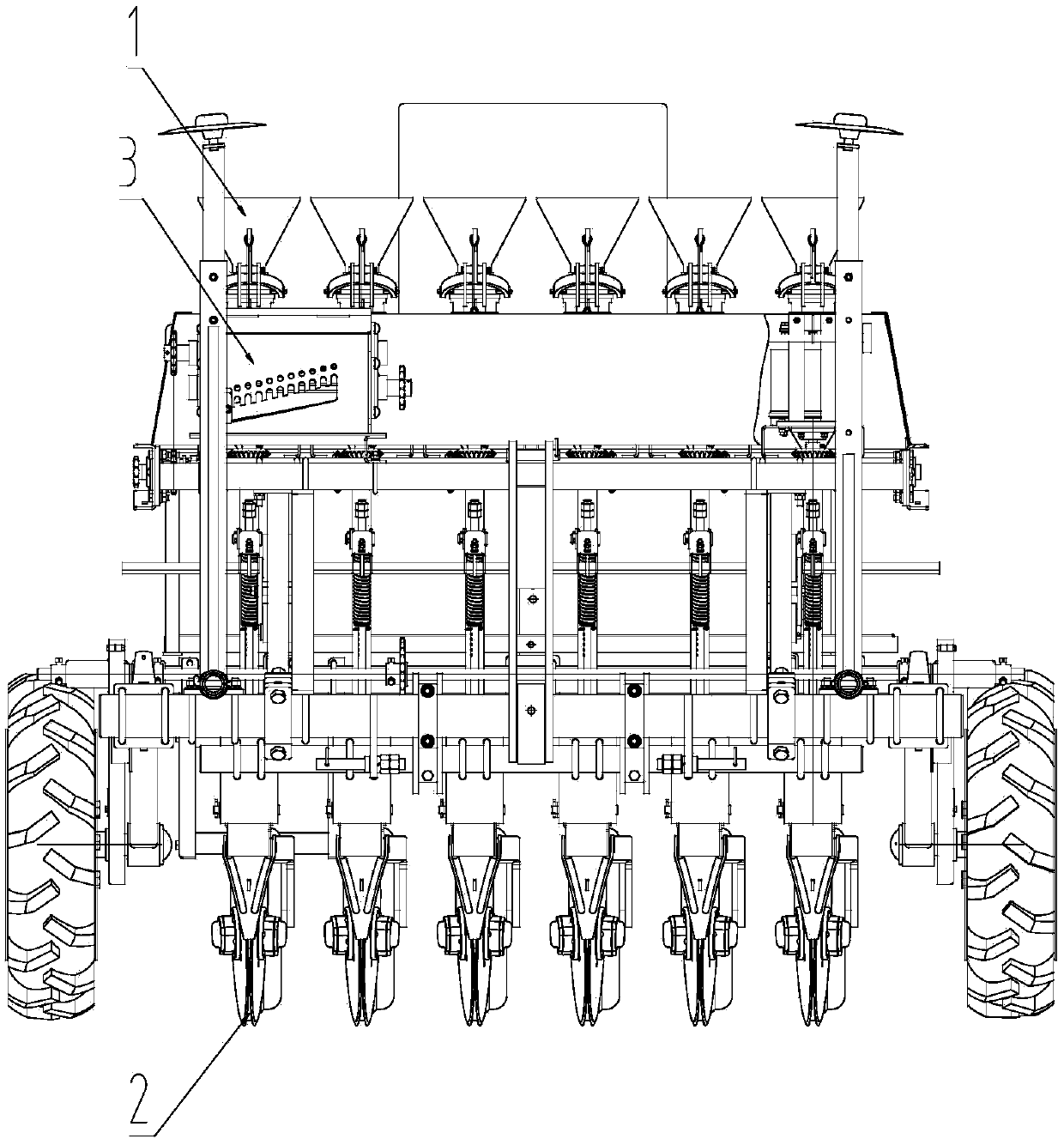

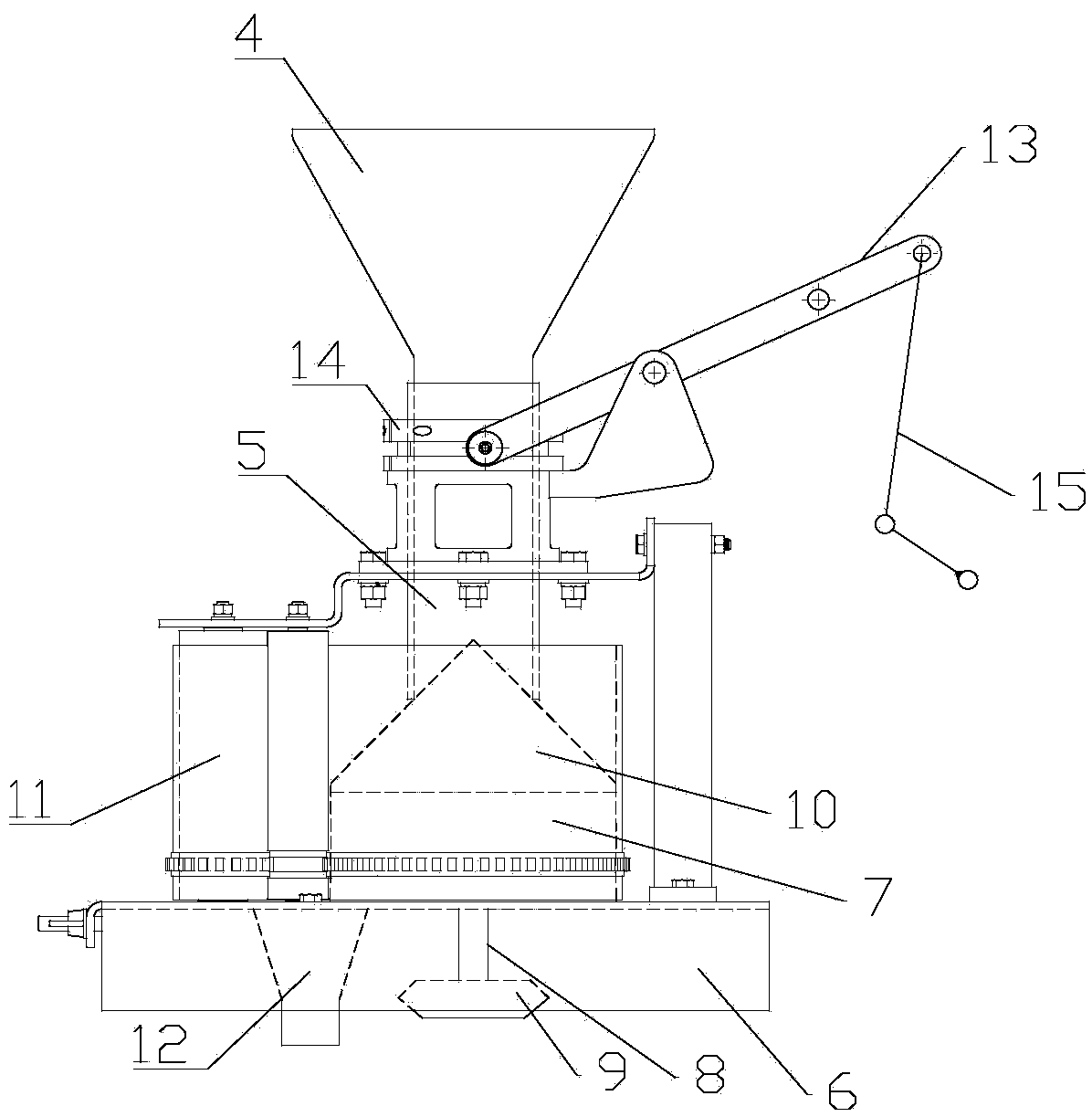

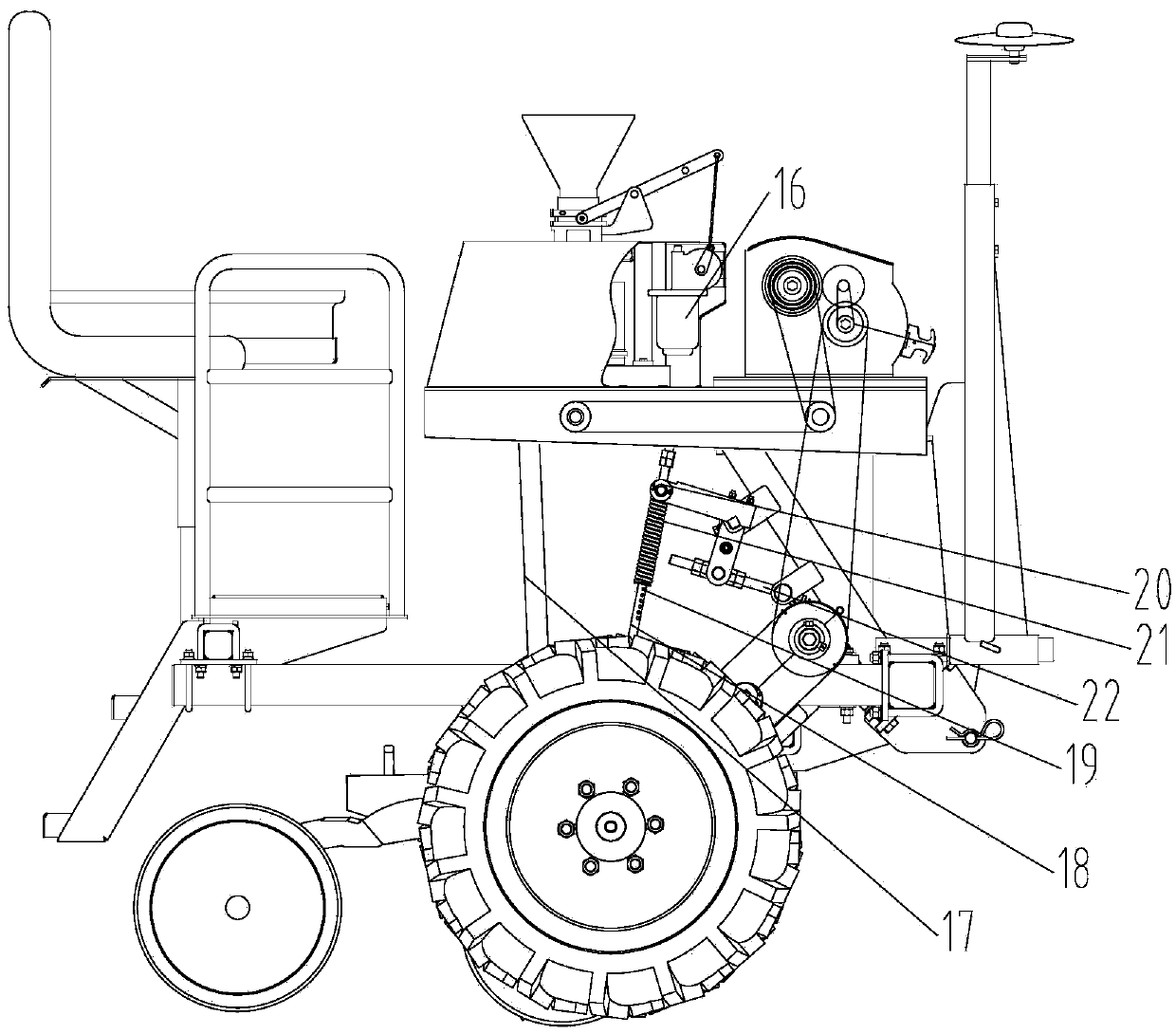

[0020] A plant row seed drill, comprising a frame and a ground wheel transmission device, markers are respectively arranged on the left and right sides of the frame, a seeding unit 1 is arranged on the frame, a ditching and soil covering device 2 is arranged under the frame, and the frame The rear part is provided with an operation table, and one side of the operation table is provided with a seed disc, which is characterized in that: the row length adjustment device 3 is installed at the front end of the frame, and the row length adjustment device 3 includes a box body, a power input device and a power output device, and the power The input device is connected with the ground wheel transmission device, the power output device is connected with the seed discharge unit 1, and the seed discharge unit includes a seed storage device, a seed discharge device and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com