Integrated machine using clean energy and used for tea withering, fixing and green-making

A clean energy, all-in-one technology, used in fluid heaters, pre-extraction tea treatment, heat storage heaters, etc., can solve problems such as carbon-to-electricity conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

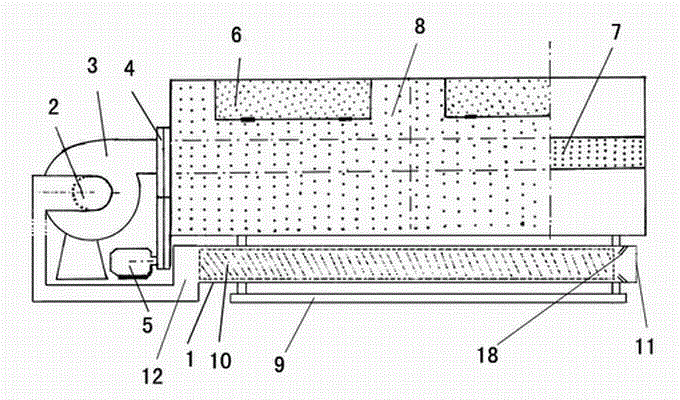

[0036] Describe below in conjunction with accompanying drawing:

[0037] attached figure 1 gives a An all-in-one machine for tea withering, greening and greening that uses clean energy, including a drum-type greening machine and a heat storage device (1) that supplies heat to the drum-type greening machine, and is characterized in that: the heat storage device (1) is a A heat storage device with an explosive heat output function, which is implemented in that the heat storage device (1) is equipped with a spray device that sprays water mist to the heat storage body (10), that is, the spray device (18) that sprays water mist is relatively Heat storage body (10) device.

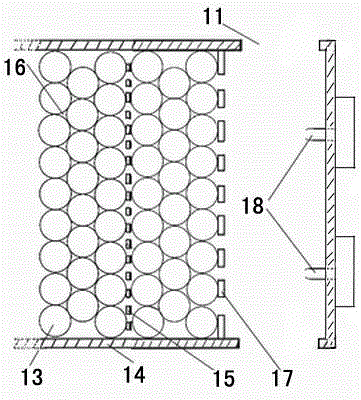

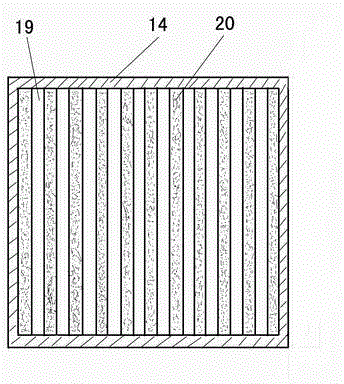

[0038] The structure of the heat storage device (1) with explosive heat output function is as follows: a spray device (18) for spraying water mist to the heat storage body (10) is provided, and the heat storage body (10) is installed in the thermal insulation shell (14 ) and the heat storage body (10) hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com