Composite cement expanding agent and preparation method thereof

A technology of compound cement and expansion agent, applied in the field of compound cement expansion agent, can solve the problems of long process and harmful expansion, and achieve the effects of improving expansion performance, increasing effective expansion and increasing plastic expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

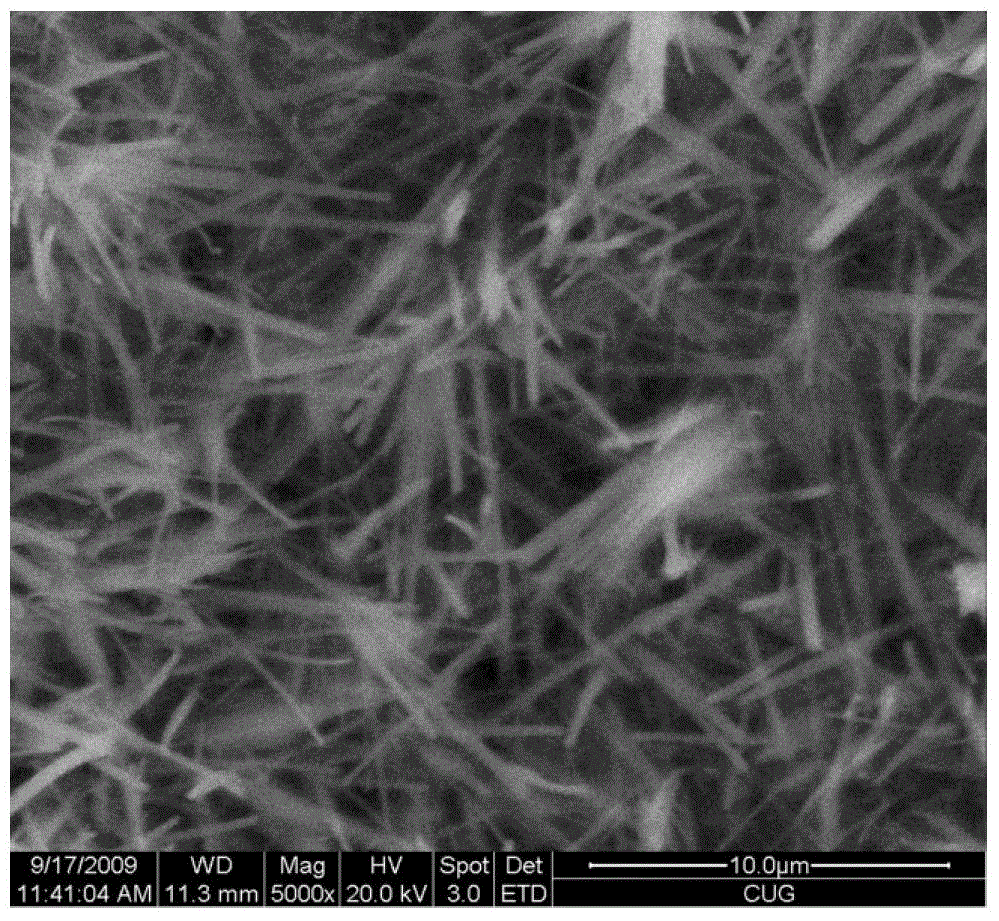

Image

Examples

Embodiment 1

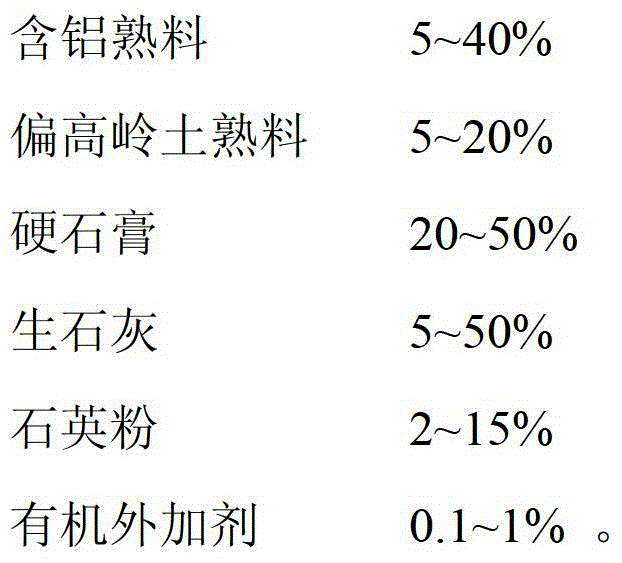

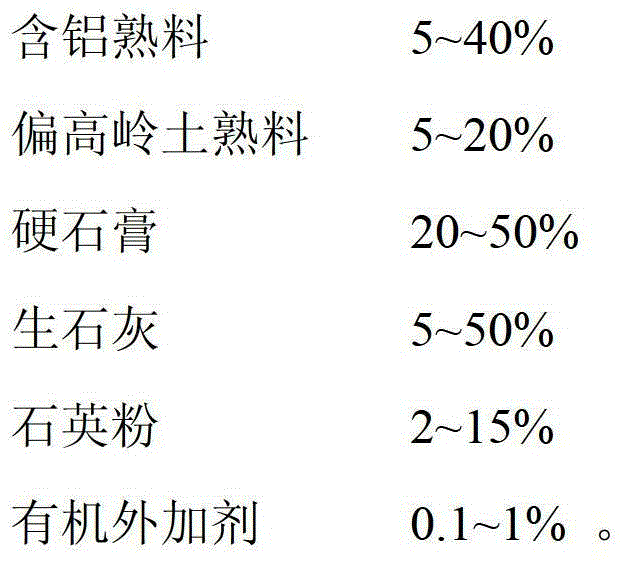

[0028] Weigh 8 g of aluminum-containing clinker, 32 g of metakaolin clinker, 35.2 g of anhydrite, 80 g of quicklime, 3.2 g of quartz powder, and 1.6 g of polyethylene glycol, mix them evenly in a mixer, and then grind to a specific surface area of 250 m. 2 / kg, made into composite cement expansion agent.

[0029] The aluminum-containing clinker is prepared from high-alumina bauxite (with an aluminum content of 86wt%) by high-temperature calcination at 1350°C; metakaolin clinker is prepared from 200-mesh kaolin by high-temperature calcination at 700°C.

[0030] According to the national standard, the composite cement expansion agent is added to 2000g cement at a dosage of 8%, and the limited expansion rate of curing in the air for 21d is 0.024%; the plastic expansion rate is 0.15%. At the same time, the flexural strength of 7d is 8.8MPa, the flexural strength of 28d is 10.7MPa, the compressive strength of 7d is 54.7MPa, and the compressive strength of 28d is 64.1Mpa, all of w...

Embodiment 2

[0033] Weigh 64g of aluminum-containing clinker, 8g of metakaolin clinker, 55.84g of anhydrite, 8g of quicklime, 24g of quartz powder, and 0.16g of naphtha, put them in a mixer and mix them evenly, and then grind to a specific surface area of 270m. 2 / kg, to make composite cement expansion agent.

[0034] The aluminum-containing clinker is prepared from high-alumina bauxite (with an aluminum content of 88wt%) by high-temperature calcination at 1400°C; metakaolin clinker is prepared from 200-mesh kaolin by high-temperature calcination at 850°C.

[0035] According to the national standard, the composite cement expansion agent is added to 2000g cement at a dosage of 8%. The limited expansion rate of curing in air for 21d is 0.012%, and the plastic expansion rate is 0.02%. At the same time, the flexural strength of 7d is 9.3MPa, the flexural strength of 28d is 11.3MPa, the compressive strength of 7d is 57.9MPa, and the compressive strength of 28d is 83.5Mpa, all of which meet t...

Embodiment 3

[0037] Weigh 37g of aluminum-containing clinker, 8g of metakaolin clinker, 80g of anhydrite, 30g of quicklime, 4g of quartz powder, and 1g of sodium lauryl sulfate, mix them evenly in a mixer, and then grind to a specific surface area of 260m 2 / kg, made into composite cement expansion agent.

[0038] The aluminum-containing clinker is prepared from high-alumina bauxite (with an aluminum content of 86wt%) by high-temperature calcination at 1400°C; metakaolin clinker is prepared from 200-mesh kaolin by high-temperature calcination at 800°C.

[0039] According to the national standard, the composite cement expansion agent is added to 2000g cement at a dosage of 8%. Curing in air for 21d limits the expansion rate to 0.029% and the plastic expansion rate to 0.15%. At the same time, the flexural strength of 7d is 10.1MPa, the flexural strength of 28d is 13.2MPa, the compressive strength of 7d is 59.3MPa, and the compressive strength of 28d is 92.1Mpa, all of which meet the requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com