Method for continuously producing acetic acid isopentenyl ester

A technology of prenyl acetate and production method, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as low reaction yield, improve reaction yield and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

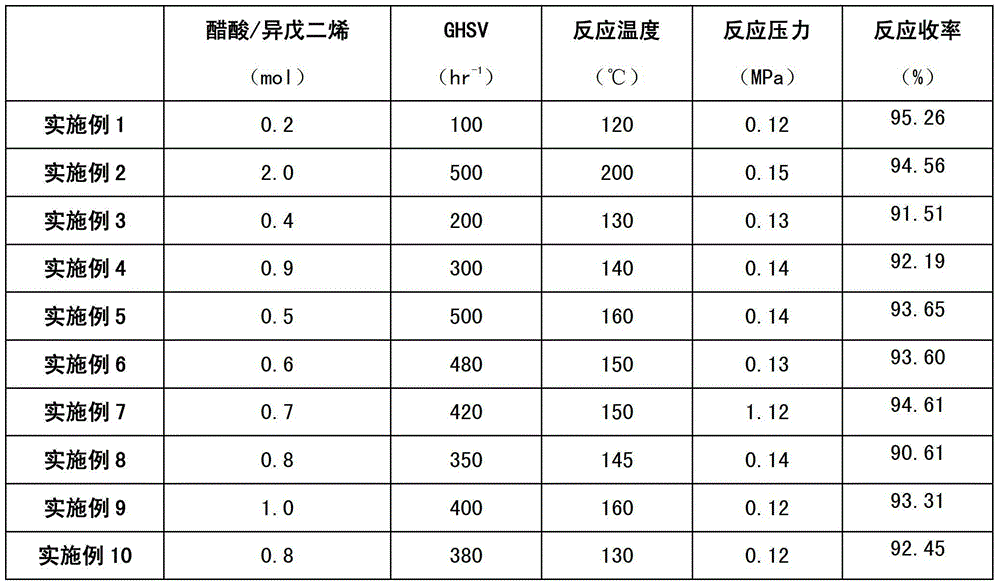

Embodiment 1~10

[0018] The esterification reaction is carried out in an acid-resistant stainless steel tubular fixed-bed reactor with a size of φ25mm×1500mm. 100 grams of Zn(AC) with a particle size of 2.5 mm are charged into the reactor 2 / C catalyst, constituting a fixed bed catalyst bed, Zn(AC) 2 The load on the carrier is 38.0-39.8% of the total mass of the catalyst. An electric heating temperature control system is installed outside the reactor, and platinum resistors for temperature measurement are respectively installed on the upper, middle and lower parts of the catalyst bed. The feeding amount of the raw materials prepared by isoprene and acetic acid is controlled by the feed pump, and the system pressure is regulated by the back pressure valve.

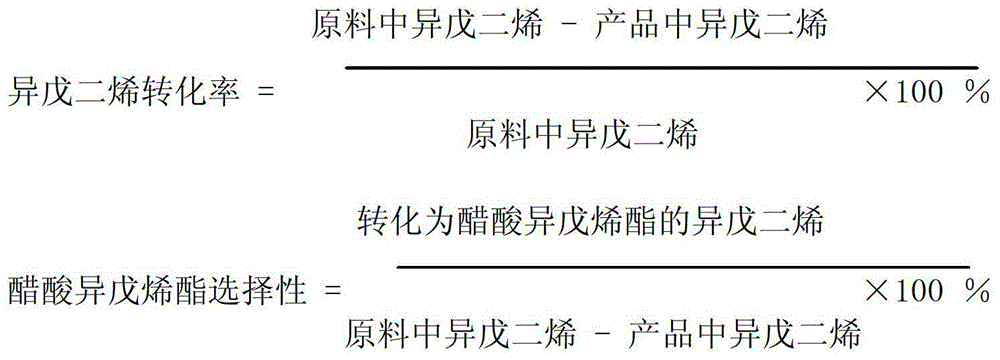

[0019] The reaction materials of the esterification reaction pass through the fixed bed according to the set feed amount, and carry out the esterification reaction according to the set reaction conditions. The reaction product obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com