Process for preparing N,N-dimethyl-1,3-propane diamine through continuous method

A technology for the reaction of dimethylaminopropionitrile and dimethylaminopropionitrile, which is applied to the preparation of amino compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low yield, achieve long life, less waste, Ease of continuous production

Active Publication Date: 2013-10-02

DALIAN UNIV OF TECH

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The second method (CN102026956A) is to obtain N,N,N',N'-substituted 1,3-propylenediamine by reacting acrolein and dimethylamine at 4°C, 0~3MPa, and the obtained mixture is mixed with ammonia gas N,N-dimethyl-1,3-propanediamine is reacted with hydrogen in the presence of a catalyst at 40-400°C and 6MPa, and the yield is about 91%. This method is green and environmentally friendly, but the yield is relatively low. The first method is low

Method used

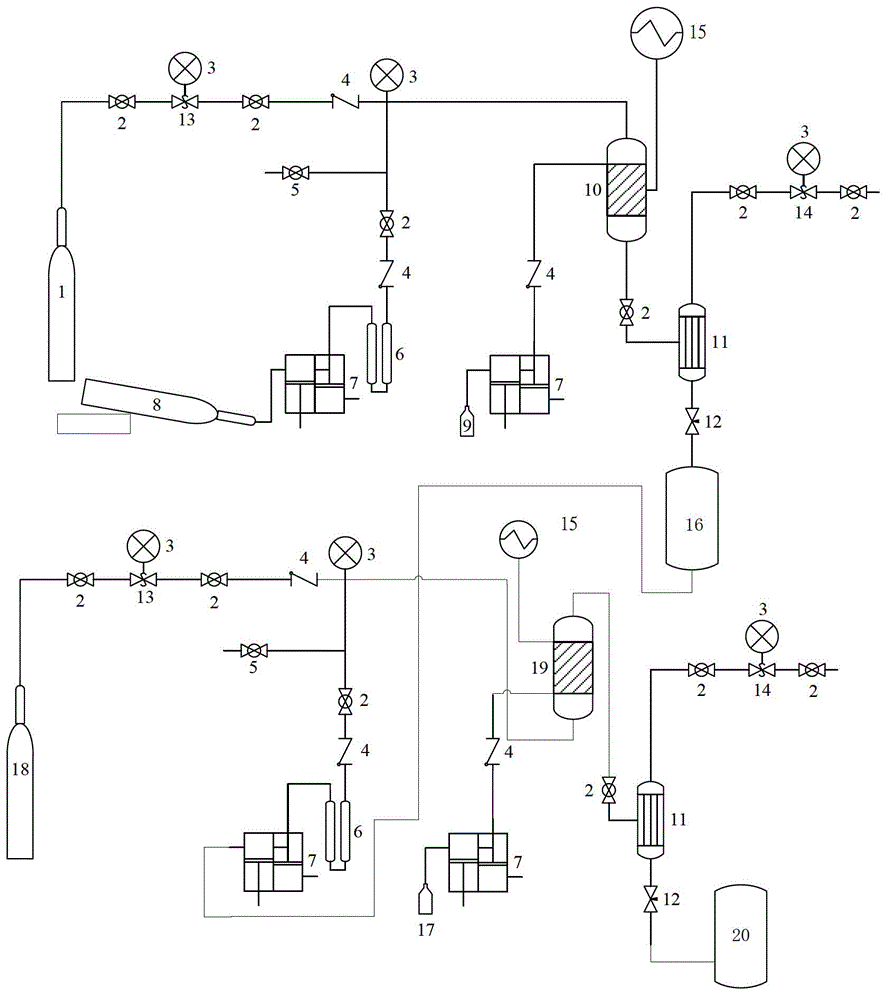

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

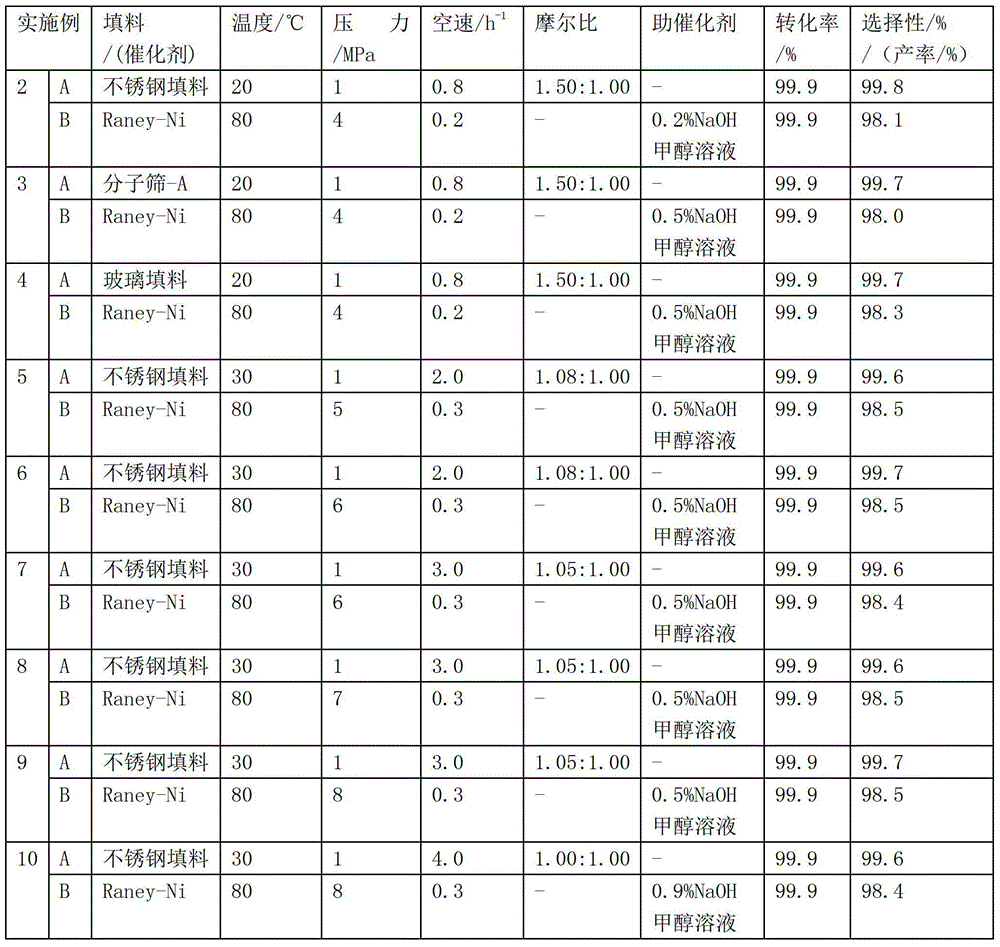

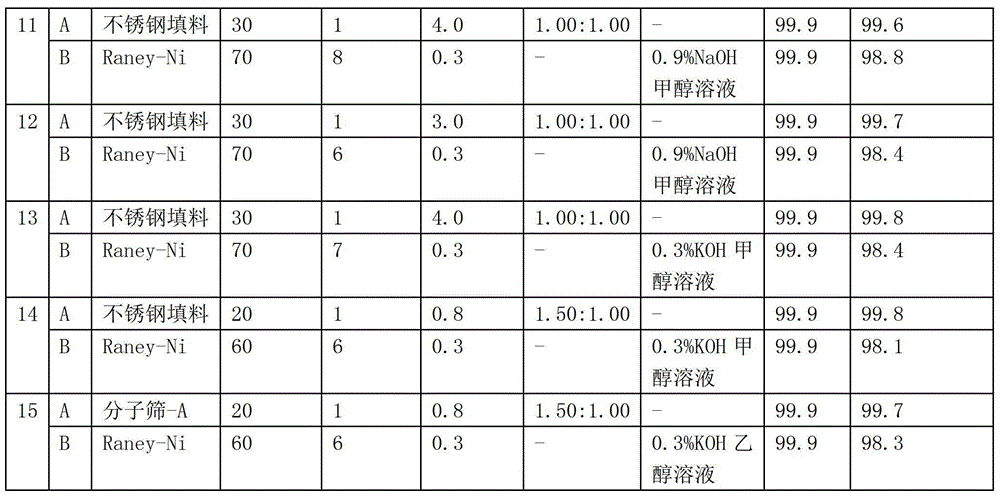

Embodiment 2~15

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a process for preparing N,N-dimethyl-1,3-propane diamine through a continuous method and belongs to the field of organic chemical industry. The process comprises the following steps: by taking dimethylamine and acrylonitrile as raw materials, continuously preparing dimethylamino propionitrile by employing a fixed bed, wherein the molar ratio of dimethylamine to acrylonitrile is (10:1)-(1:1), the reaction temperature is 10-120 DEG C, the air speed is 0.1-10h<-1>, and the conversion rate of the acrylonitrile and the selectivity of the dimethylamino propionitrile are over 99 percent; and allowing the obtained dimethylamino propionitrile intermediate to directly enter a second fixed bed reactor for hydrogenating without any purification treatment, wherein the hydrogenation pressure is 3-10 MPa, a Raney-Ni catalyst is used, an alcoholic solution promoter with 0.1-10 percent of alkali is matched, the air speed is 0.1-4h<-1>, and the yield of N,N-dimethyl-1,3-propane diamine is not lower than 93 percent. The process for preparing N,N-dimethyl-1,3-propane diamine is simple, stable in quality, energy-saving and environment-friendly and is suitable for large-scale production.

Description

technical field [0001] The invention belongs to the technical field of organic chemical industry and relates to a process for preparing N,N-dimethyl-1,3-propanediamine by continuous method Background technique [0002] N,N-Dimethyl-1,3-propanediamine belongs to lower aliphatic diamine and is an important chemical intermediate widely used in the preparation of detergents, surfactants, textiles, lubricating oil additives, gasoline additives, Preservatives, moisturizing agents, foaming agents, etc. With the advancement of science and technology and social development, the scope of application of DMAPA has also been expanding accordingly, and the market demand has also increased year by year. Therefore, N,N-dimethyl-1,3-propanediamine is a very potential organic chemical intermediate. [0003] There are two main methods for preparing N,N-dimethyl-1,3-propanediamine. The first one uses acrylonitrile and dimethylamine as raw materials to prepare N,N-dimethyl-1,3-propanediamine;...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C211/11C07C209/48

Inventor 孟庆伟邓朝芳都健李亚楠卿海

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com