Method for preparing transparent green glow yellow pigment C.I.P.Y180

A yellow pigment and green light technology, applied in the direction of organic dyes, etc., can solve the problems of high energy consumption, long process flow, and limitations, and achieve the effects of reducing the use of organic solvents, simple reaction conditions, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

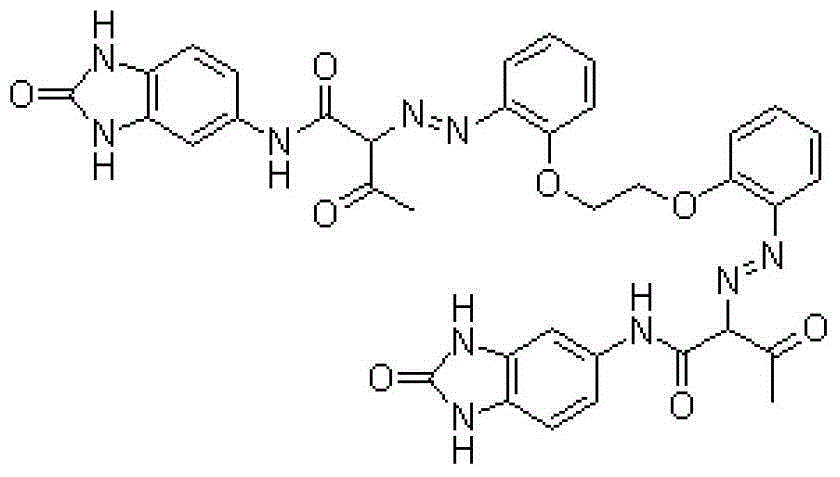

Image

Examples

Embodiment 1

[0020] A preparation method of transparent green light yellow pigment C.I.P.Y180 comprises the following steps:

[0021] 1) Take 23.5g of 2,2'-diaminoethylene glycol diphenyl ether, 1.0g of 2,2'-diaminoethylene glycol diphenyl ether, 50g of HCl with a concentration of 36% and 500mL of water, dissolve and cool to 0~5 ℃, adding NaNO to it 2 To excess, after stirring for 3 hours, react with urea to remove excess nitrous acid, then decolorize and filter to obtain diazonium salt solution, add ice water to adjust the volume to 1000mL for later use;

[0022] 2) Take 57.2 g of 5-acetoacetamidobenzimidazolone, add it to 500 mL of water, add 37.3 g of potassium hydroxide to dissolve and filter it, collect the filtrate and add pure water to adjust the volume to 1050 mL, and obtain the coupling component for later use;

[0023] 3) Take 107g of sodium acetate, add it to 2000mL of water, add 5g of auxiliary hyperdispersant, 30g of acetic acid, and configure it into a buffer solution. After...

Embodiment 2

[0026] A preparation method of transparent green light yellow pigment C.I.P.Y180 comprises the following steps:

[0027] 1) Take 21.5g of 2,2'-diaminoethylene glycol diphenyl ether, 3.0g of 2,2'-diaminoethylene glycol diphenyl ether, 60g of 36% HCl and 500mL of water, dissolve and cool to 0~5 After ℃, add NaNO to it 2 To excess, stir for 3 hours, react with urea to remove excess nitrous acid, then decolorize and filter to obtain diazonium salt solution, add ice water to adjust the volume to 1000mL for later use;

[0028] 2) Take 57.2 g of 5-acetoacetamidobenzimidazolone, add it to 500 mL of water, add 37.3 g of potassium hydroxide to dissolve and filter it, collect the filtrate and add pure water to adjust the volume to 1050 mL, and obtain the coupling component for later use;

[0029] 3) Take 107g of sodium acetate, add it to 2000mL of water, add 5g of auxiliary hyperdispersant, 30g of acetic acid, and configure it into a buffer solution. After controlling the temperature at...

Embodiment 3

[0032] A preparation method of transparent green light yellow pigment C.I.P.Y180 comprises the following steps:

[0033] 1) Take 21.5g of 2,2'-diaminoethylene glycol diphenyl ether, 3.0g of 2,2'-diaminoethylene glycol diphenyl ether, 60g of 36% HCl and 500mL of water, dissolve and cool to 0~5 ℃, adding NaNO to it 2 To excess, stir for 3 hours, react with urea to remove excess nitrous acid, then decolorize and filter to obtain diazonium salt solution, add ice water to adjust the volume to 1000mL for later use;

[0034] 2) Take 57.2 g of 5-acetoacetamidobenzimidazolone, add it to 500 mL of water, add 37.3 g of potassium hydroxide to dissolve and filter it, collect the filtrate and add pure water to adjust the volume to 1050 mL, and obtain the coupling component for later use;

[0035] 3) Take 107g of sodium acetate, add it to 2000mL of water, add 5g of auxiliary hyperdispersant, 30g of acetic acid, and configure it into a buffer solution. After controlling the temperature at 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com