Method for preparing Beta-glucuronidase crude enzyme preparation

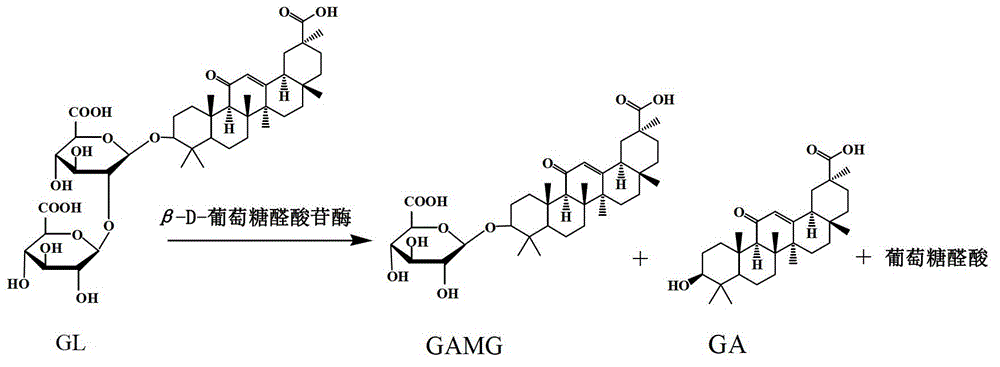

A crude aldolase and aldolase technology, which can be applied in microorganism-based methods, biochemical equipment and methods, hydrolase and other directions, and can solve problems such as low enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, only using glycyrrhizic acid monoammonium salt as inducer to produce enzyme implementation method:

[0031] Inoculate the Penicillium purpurea Li-3 strain on the slant medium, and cultivate it at a constant temperature of 30°C for 3 days. The composition of the slant medium is: glucose 0.5g, NH 4 NO 3 0.3g, KH 2 PO 4 0.1g, KCl0.05g, MgSO 4 ·7H 2 O0.05g, FeSO 4 ·7H 2 O0.001g, distilled water 100mL, agar 1.5g, adjust the pH to 5.0, sterilize at 121°C for 20min, and cool to room temperature.

[0032] Take the spores on the slant medium, inoculate them into the seed medium, and culture them on a shaker at 30°C at 170r / min for 72h, then transfer 5% of the inoculum into the secondary seed medium at 30°C on a shaker at 170r / min Cultivate for 24 hours to obtain secondary seed liquid, the composition of the seed medium is: glucose 0.5g, NH 4 NO 3 0.3g, KH 2 PO 4 0.1g, KCl0.05g, MgSO 4 ·7H 2 O0.05g, FeSO 4 ·7H 2 O0.001g, 100mL of distilled water, adju...

Embodiment 2

[0034] Example 2, the implementation method of adding exogenous accelerator to produce enzymes of monoammonium glycyrrhizinate:

[0035] Slope culture and seed culture are the same as in Example 1.

[0036] Put the secondary seed liquid into the enzyme-producing medium according to the inoculation amount of 10% by volume, and culture it on a shaker at 30°C and 170r / min for 72 hours to reach the maximum specific enzyme activity of 157U / mg. solution as a crude enzyme preparation. The composition of the enzyme production medium: monoammonium glycyrrhizinate 0.6g, licorice total extract 0.4g, NH 4 NO 3 0.3g, KH 2 PO 4 0.1g, KCl0.05g, MgSO 4 ·7H 2 O0.05g, FeSO 4 ·7H 2 O0.001g, 100mL of distilled water, adjust the pH to 5.0, sterilize at 121°C for 20min, and cool to room temperature.

Embodiment 3

[0038] Slope culture, seed culture, and enzyme production culture are the same as in Example 1.

[0039] Put the secondary seed solution into the enzyme-producing medium according to the inoculation amount of 10% by volume, and cultivate it on a shaker at 30°C and 170r / min for 60 hours to reach the maximum specific enzyme activity of 135U / mg. The fermentation broth is centrifuged to collect the bacteria. 47.8 mg of crude enzyme freeze-dried powder was obtained as crude enzyme preparation after the body was freeze-dried and ground. Composition of enzyme production medium: 0.6g monoammonium glycyrrhizinate, 0.25g licorice total polysaccharide, NH 4 NO 3 0.3g, KH 2 PO 4 0.1g, KCl0.05g, MgSO 4 ·7H 2 O0.05g, FeSO 4 ·7H 2 O0.001g, 100mL of distilled water, adjust the pH to 5.0, sterilize at 121°C for 20min, and cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com