led light source module and its led street lamp

A technology of LED light source and PCB board, applied in the direction of light source, electric light source, semiconductor devices of light-emitting elements, etc., can solve the problems of increasing the use cost of LED street lamps, low one-time success rate of welding light source, and increasing the difficulty of design, etc. Comprehensive utilization efficiency, saving development investment cost, good effect of waterproof and dustproof environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the description.

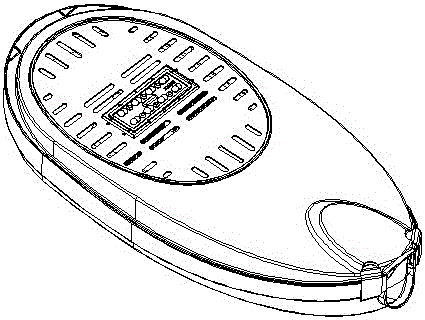

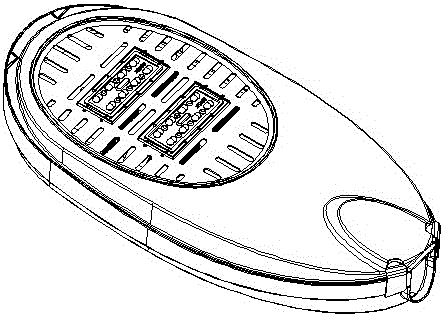

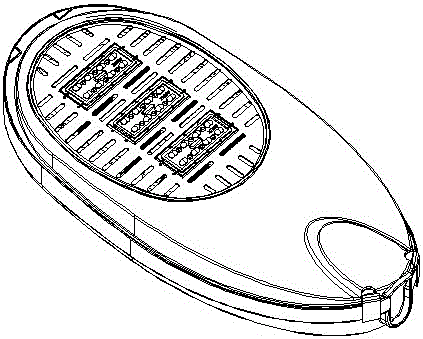

[0027] see figure 1 with figure 2 , a LED light source module, consisting of a lens cover 2, a lens 1 arranged in an array on the lens cover 2, a sealing ring 3, a PCB board 5, an LED light source 4 arranged on the PCB board 5, and a heat sink 6. The fins 7 arranged on the back of the heat sink 6, the rubber plug 9, the pressure plate 10, the concave hole 11 and the through hole 12 arranged in the middle of the heat sink 6 are composed; the fins 7 are provided with a fin gap 8 in the vertical direction, The LED light source 4 array is arranged on the PCB board 5, and the PCB board 5 is installed on the front of the heat sink 6, and the heat conduction paste is coated between the PCB board 5 and the heat sink 6, and the sealing ring 3 closely surrounds the edge of the PCB board 5 , the lens surface cover 2 is covered on the PCB board 5, and the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com