Plate hose clogging test machine

A testing machine and hose technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of certain hidden dangers in product quality assurance, low efficiency of manual testing, and high labor costs, so as to facilitate quality tracking, reduce human interference, and save money. The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

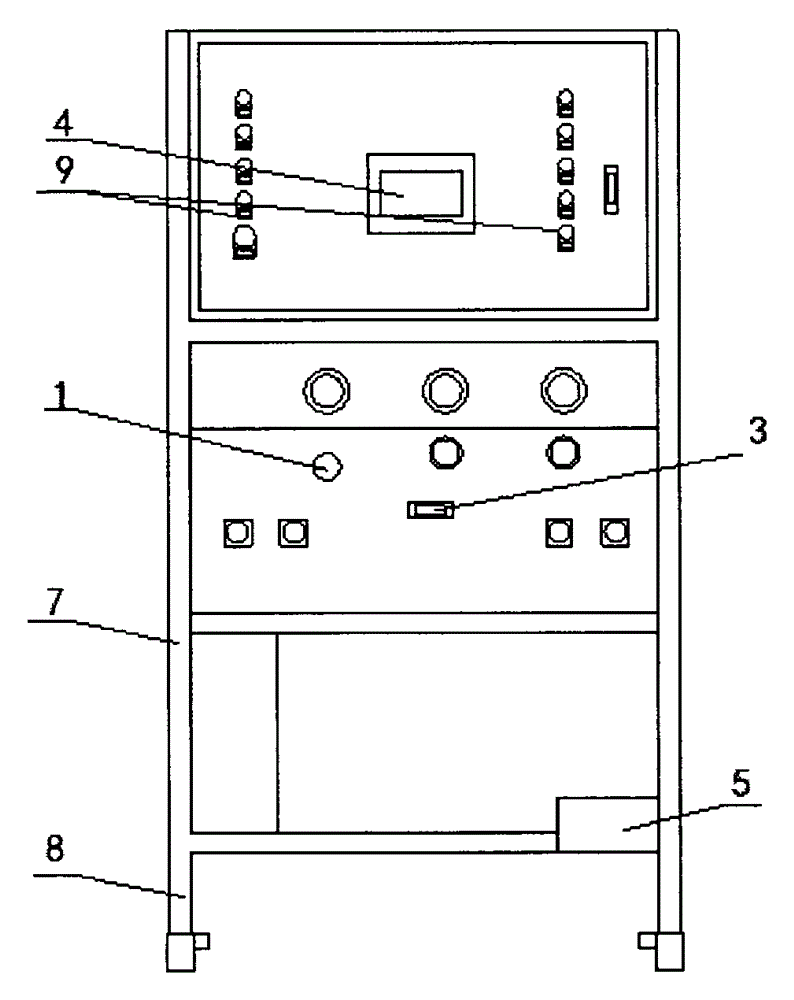

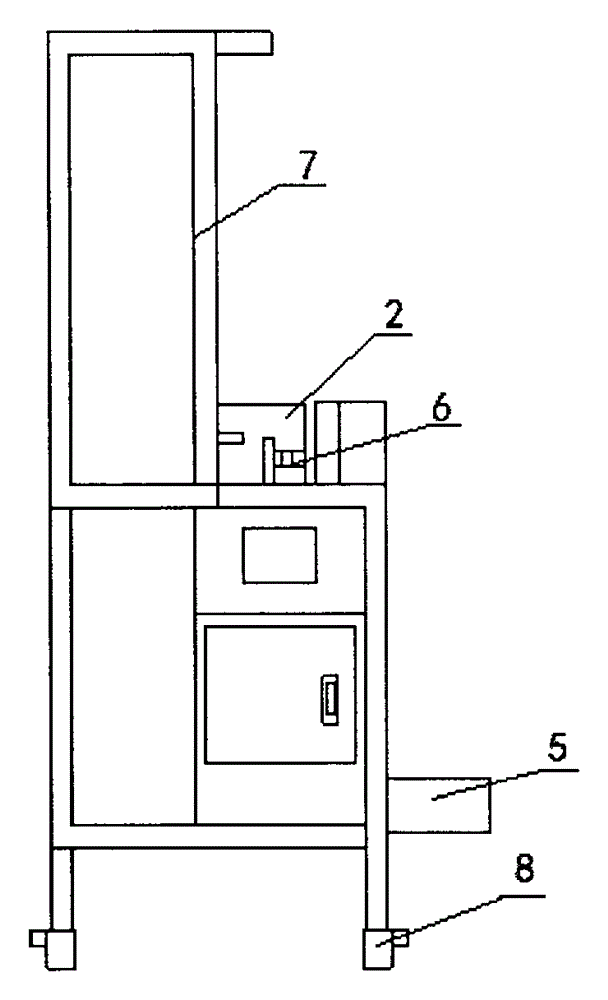

[0013] The present invention provides a kind of board rubber hose clogging testing machine for existing deficiency, as figure 1 with figure 2 As shown, it includes the foot 8, the frame 7 which is integrated and fixed by the foot 8, the control system for controlling the operation of the equipment, and the rubber hose set in the frame 7 for transporting metal detection particles, and also includes the Metal detection particle recovery box 5, blowing nozzle 1 and recovery pipe 2, the blowing nozzle 1 is connected to the head of the rubber hose, the recovery pipe 2 is connected to the tail of the rubber hose, the recovery pipe 2 is provided with an inductor 3, the The nozzle of the recovery pipe 2 is also connected with a recovery box 5 for recovering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com