Palladium nano particle dot matrix hydrogen sensor with controllable sensing parameters

A nanoparticle, palladium nanotechnology, applied in the field of hydrogen sensors, can solve problems such as limited application, complicated preparation methods, and breakage of Pd nanowires, achieving low cost and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below. And illustrate the realization process of the present invention and the practicability of invention by an example:

[0034] 1) Use PET with a thickness of 0.5mm as the substrate, and the substrate area is 10×10mm.

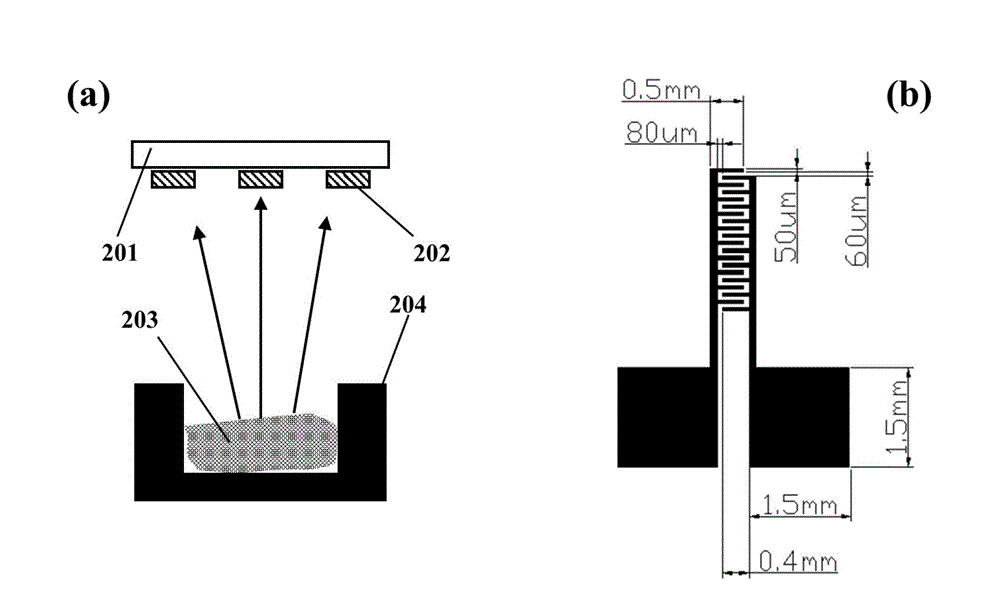

[0035] 2) if figure 2(a), the metal electrode is prepared on the above-mentioned substrate by masking the thermal evaporation coating process. By heating the evaporation boat 204, the metal raw material 203 in the heating evaporation boat 204 is volatilized to form atomic vapor deposited on the surface of the PET substrate 201 to form a metal electrode. Here, the metal material is selected to be gold which has good conductivity and is not easily oxidized. In order to obtain a metal electrode with a specific shape, the mask 202 is used as a shield. The mask plate 202 is made of molybdenum by wet etching. The structure of the prepared electrode substrate is as follows figure 2 (b) shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com