Pinhole collimator

A technology of collimator and pinhole, which is applied in the field of collimator, can solve the problems of large heavy ion beam spot, unsatisfactory pinhole shape, and low-energy scattering of heavy ion micro-beam, so as to reduce low-energy scattering components and achieve good straightness , reducing the effect of low-energy scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

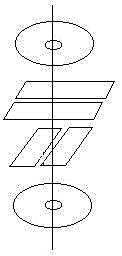

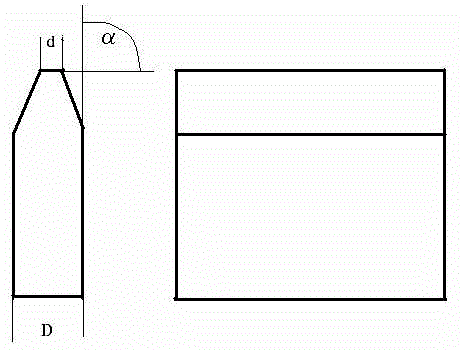

[0023] A pinhole collimator, comprising an upper substrate, a first slit structure, a second slit structure and a lower substrate; the first slit structure and the second slit structure are made of It is composed of two blades with opposite cutting edges, and there is a slit between the opposite cutting edges, and the thickness of the cutting edge is required to ensure that the collimated object will not be transmitted; the two blades of the first slit structure are formed by the upper substrate fixed together, the two blades of the second slit structure are fixed together by the lower substrate; the upper substrate leaves an opening that makes the partial slit of the first slit structure not blocked, and the lower substrate leaves an opening that makes Part of the slit opening of the second slit structure is not blocked; the integral structure formed by the upper substrate and the first slit structure is stacked and fixed with the integral structure formed by the lower substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com