Method for improving safety of lithium ion secondary battery

A secondary battery, lithium-ion technology, applied in the field of lithium-ion batteries, can solve problems such as adverse effects on battery electrochemical performance, lower battery energy density, and inability to protect battery from overcharge, so as to prevent overcharge and thermal runaway and ensure contact tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

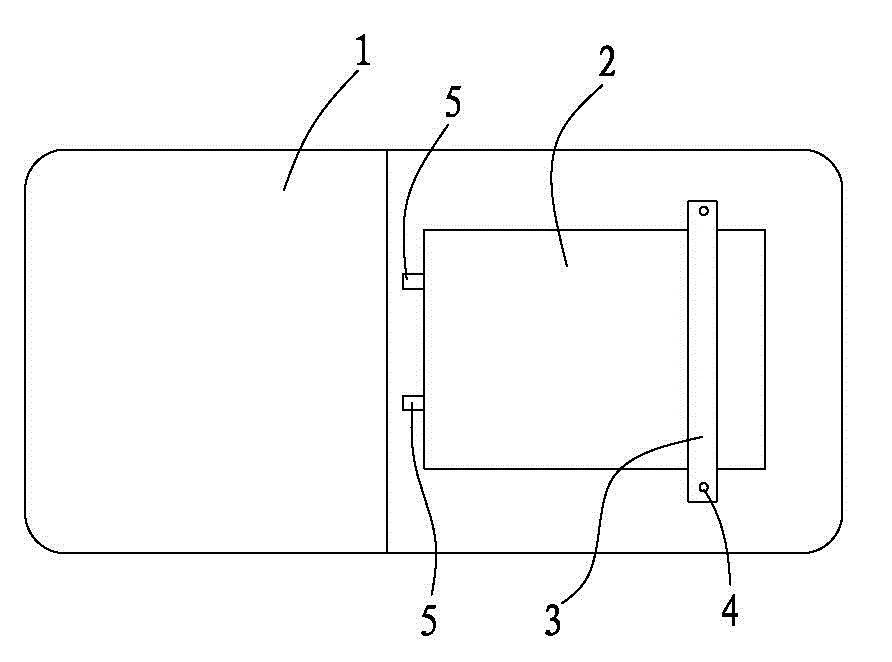

[0021] Example 1, Such as figure 1 As shown, a method for improving the safety of lithium-ion secondary batteries includes the following steps: Step 1. Use two very flat steel metal sheets (length 80mm, width 40mm, and thickness 0.5 mm) with screw holes 4 at both ends. 1) It can be made to uniformly press the surface of the lithium ion secondary battery 2 and facilitate the adjustment of the clamp piece 3 with a small pressure; step two, arrange the clamp piece 3 on the upper and lower surfaces of the lithium ion secondary battery 2, and then place the clamp piece 3 Both ends are fixedly connected with devices 1 (including mobile phones, tablet computers, notebook computers, navigators, and mobile routers, etc.) using lithium ion secondary batteries 2 through screws. This embodiment uses a tablet computer.

[0022] The shape of the clamp piece 3 is rectangular, and the longitudinal direction of the clamp piece 3 is perpendicular to the extension direction of the tab 5 of the lith...

Embodiment 2

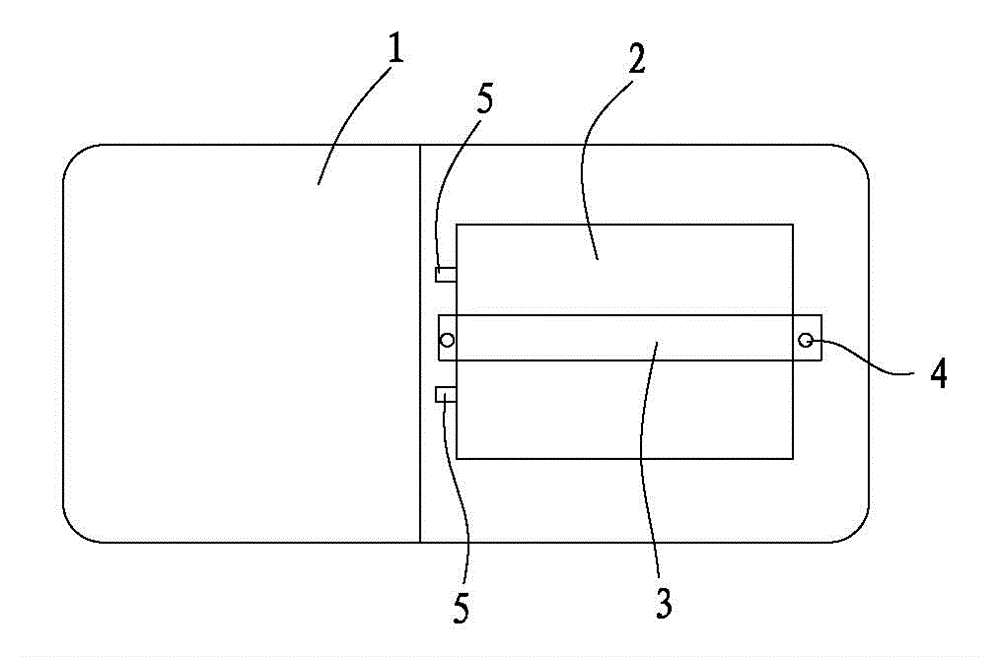

[0025] Example 2, Such as figure 2 As shown, a method for improving the safety of lithium-ion secondary batteries includes the following steps: Step 1. Use two very flat copper foils with screw holes 4 at both ends (length 91mm, width 50mm, and thickness 1 mm). 1) It can be made to uniformly press the surface of the lithium ion secondary battery 2 and facilitate the adjustment of the clamp piece 3 with a small pressure; step two, arrange the clamp piece 3 on the upper and lower surfaces of the lithium ion secondary battery 2, and then place the clamp piece 3 Both ends are fixedly connected with devices 1 (including mobile phones, tablet computers, notebook computers, navigators, and mobile routers, etc.) using lithium ion secondary batteries 2 through screws. This embodiment uses a tablet computer.

[0026] Preferably, the shape of the clamp piece 3 is rectangular, the longitudinal direction of the clamp piece 3 is parallel to the extension direction of the tabs 5 of the lithium...

Embodiment 3

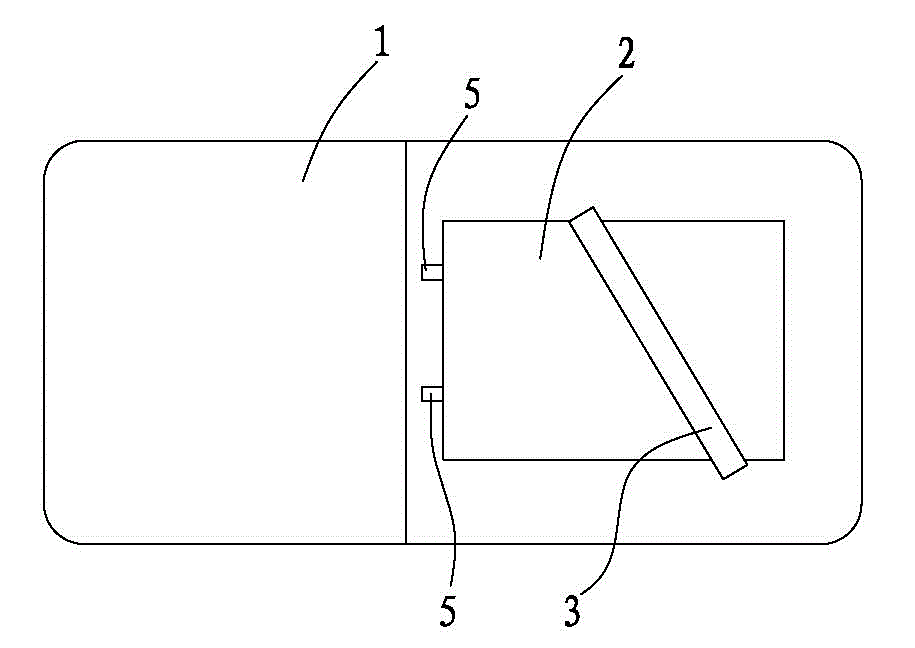

[0029] Example 3, Such as image 3 As shown, a method for improving the safety of lithium-ion secondary batteries includes the following steps: Step 1. Use two very flat iron metal flakes (length 70mm, width 35mm, thickness 1.2 mm) to make lithium ion The surface of the secondary battery 2 is uniformly pressed, and it is convenient to adjust the clamping piece 3 with a small pressure; step two, dispose the clamping piece 3 on the upper and lower surfaces of the lithium ion secondary battery 2, and then connect the two ends of the clamping piece 3 with the use of lithium ion The equipment 1 of the secondary battery 2 (including mobile phones, tablet computers, notebook computers, navigators, mobile routers, etc.) is fixed by glue bonding, and a mobile phone is used in this embodiment.

[0030] Preferably, the shape of the clamp piece 3 is rectangular, the long side direction of the clamp piece 3 is at an acute angle with the extension direction of the tab 5 of the lithium ion seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com