Electric hot-water bag utilizing phase change latent heat and manufacturing method thereof

An electric hot water bag, phase change latent heat technology, applied in heat exchange materials, chemical instruments and methods, heating appliances for treatment, etc., can solve the problem of no electric hot water bag, achieve long-lasting heating effect, prevent burns, and The effect of heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

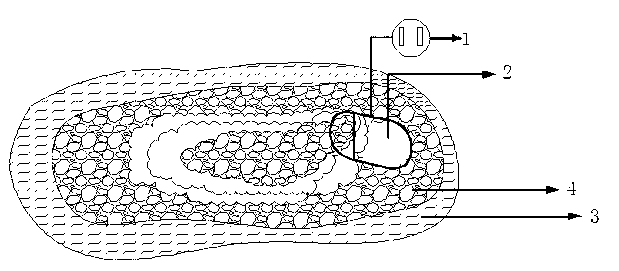

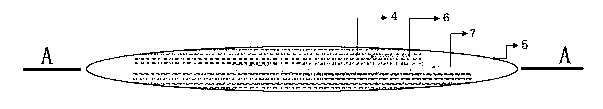

[0029] In this example, see Figure 1 ~ Figure 3, an electric hot water bag using phase change latent heat, which is composed of an outer layer 5 of the electric hot water bag, a heating element 7, an insulating material and a heat storage liquid 3 filled, the outer layer 5 of the electric hot water bag is sealed to form a sealed cavity, and the filled heat storage is injected into the sealed cavity The liquid 3 and the heating element 7 are arranged in the sealed cavity. The heat output part of the heating element 7 outputs heat to the heat storage liquid 3. One end of the heating element 7 forms the positive and negative electrodes 2, and the outer surface of the positive and negative electrodes 2 is covered with an insulating material. Insulation, the positive and negative electrodes 2 are connected to the power plug 1 outside the outer layer 5 of the electric hot water bag through wires, and an energy storage material layer 4 is provided inside the heat storage liquid 3, an...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, especially in that:

[0037] In this embodiment, it is taken as an example that the volume of the electric hot water bag utilizing phase change latent heat in this embodiment is 1000ml. In order to make the hot water bag store a large amount of heat energy while distributing the heat evenly, according to the theoretical calculation and experimental results, it is concluded that the volume occupied by filling the heat storage liquid 3 is 570ml, and that of the energy storage material is 430ml. The mass percentages of the components in the energy storage material are: 88% sodium acetate trihydrate, 10% sodium sulfate and 2% carboxymethyl cellulose.

[0038] In this embodiment, the method for making an electric hot water bag utilizing latent heat of phase change comprises the following steps:

[0039] a. Preparation of energy storage material layer composition system: using sodium acetate trihydrate as phase change ma...

Embodiment 3

[0054] This embodiment is basically the same as the previous embodiment, and the special features are:

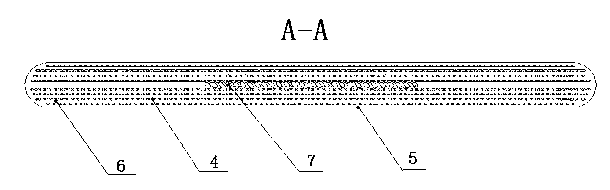

[0055] In this example, see Figure 4 , in the same layer of energy storage material layer 4 structural layer, the single-layer structural layer of energy storage material layer 4 is separated into different blocks by using low thermal conductivity material interlayer 6, so that the low thermal conductivity material of energy storage material layer 4 The interlayer 6 is connected to form an integral space partition frame, which separates different blocks of the energy storage material layer 4, so that the energy storage material layer 4 forms a layered array composite material structure. Through the coating method, the mixed solution of the energy storage material layer 4 is orderly dispersed in the form of an array between the two layers of butyl rubber material, forming a phase-change material block distributed in the form of an array. The gaps between the variable mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com