Three-freedom-degree constant speed decoupling space robot active spherical wrist and universal compliant control method

A technology of space robots and constant velocity universal joints, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problem that there is no three-degree-of-freedom constant-velocity decoupling spherical wrist universal compliant control mode of space robots, and achieve uniform velocity control Simple and easy to operate, eliminate interactive interference force, and achieve accurate rotation angle control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

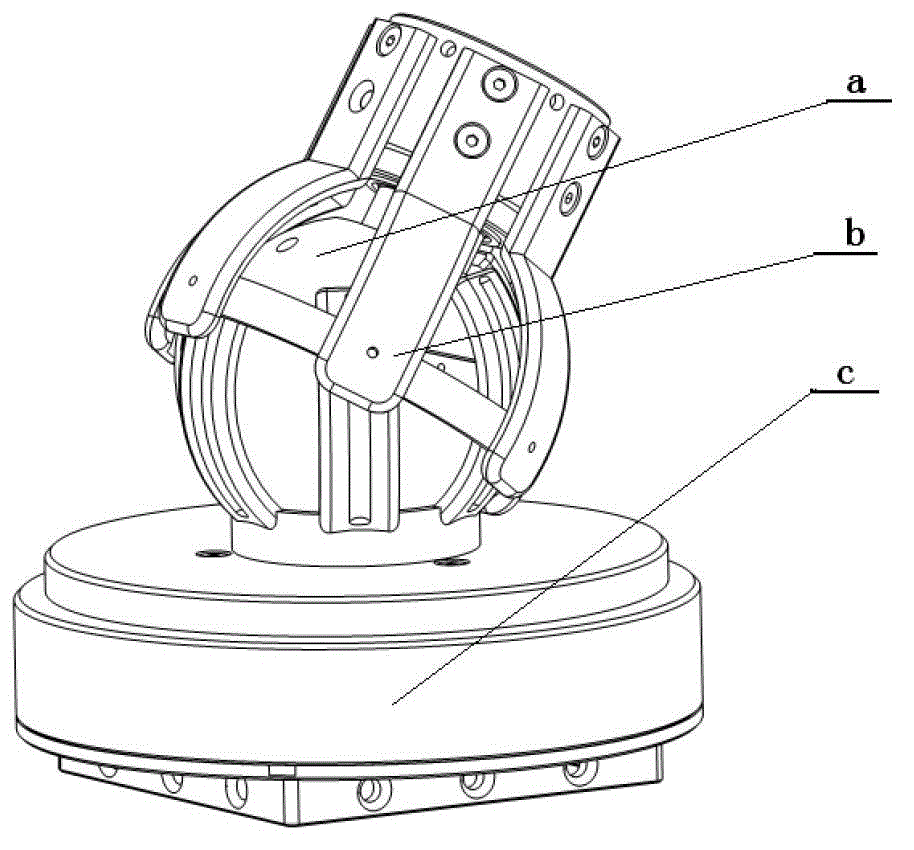

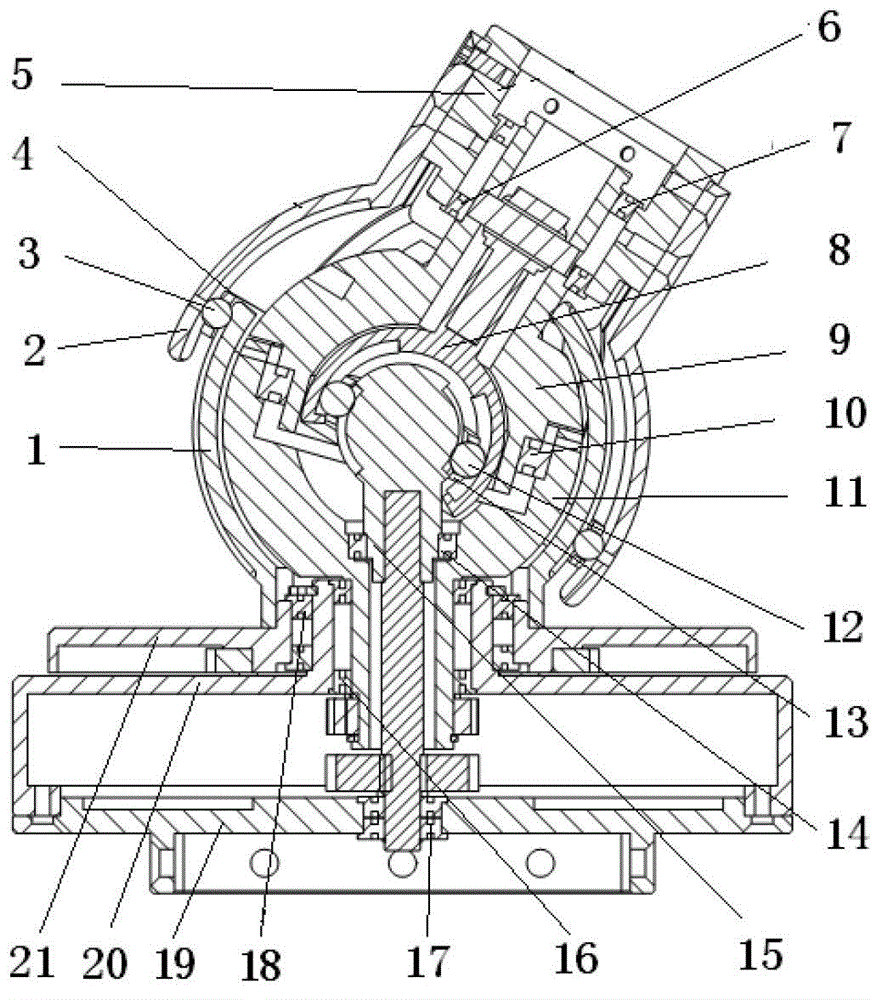

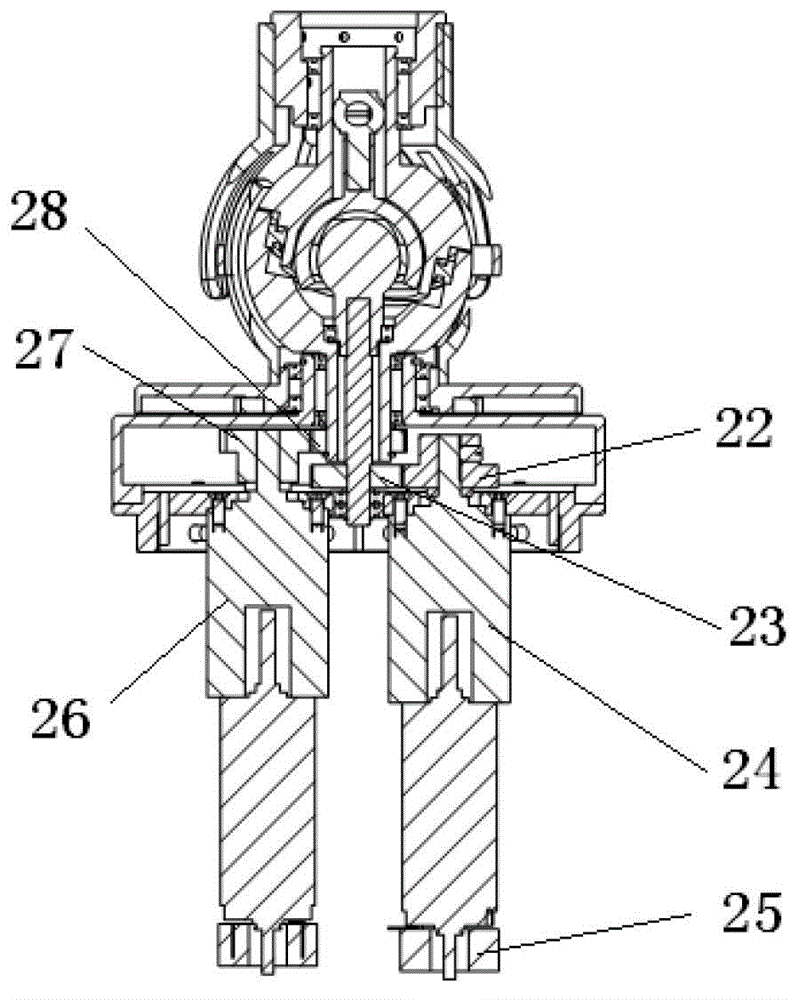

[0056] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0057] combined with figure 2 , Figure 3(A) and 3(C) Explain the realization of the three-degree-of-freedom constant-velocity decoupling spherical wrist side swing and pitch motion. The active wrist of the three-degree-of-freedom constant-velocity decoupling spherical robot includes an internal spherical cage constant velocity universal joint, which includes a spherical shell 8, six Steel ball 12, steel ball cage 13 and star-shaped sleeve 15, the power is transmitted from star-shaped sleeve 15 to spherical shell 8 through steel ball 12 for output, spherical shell 8 and star-shaped sleeve 15 have the same spherical center, that is, the inner spherical cage is constant velocity The center of rotation of the gimbal.

[0058]The side swing and pitch motion mechanism of the active wrist of the three-degree-of-freedom consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com