Crude iodine purifying process

A process, the technology of iodine vapor, applied in the field of purification of crude iodine, to achieve the effects of recycling and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

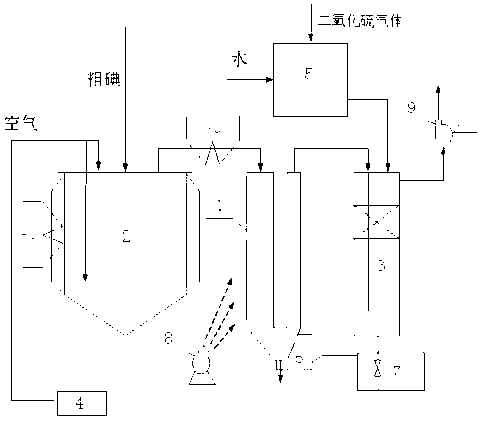

[0020] A crude iodine purification process, comprising the steps of:

[0021] (1) Add crude iodine into the ceramic reaction kettle, and add soda ash with a mass percentage of 2 to 5%;

[0022] (2) Start the heating device to heat the reactor, and control the temperature of the reactor at 120-180°C;

[0023] (3) Insert the air pipe into the reaction kettle, and turn on the compressor to blow out the iodine vapor; the flow rate of the air blowing gas is 0.5~5m 3 / h, the flow rate of bubbling air gas is 1~3m 3 / h;

[0024] (4) Blow out the iodine vapor to cool and crystallize in the desublimer to collect the final product, refined iodine;

[0025] (5) The tail gas coming out of the desublimer enters the washing tank for washing, and the tail gas washed by the washing liquid is discharged through the fan, and trace iodine in the tail gas is recovered at the same time.

[0026] The mass percent of iodine in the crude iodine in the above step (1) is 50-90%.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com