Environment-friendly wood veneer dyeing method

An environmentally friendly wood veneer technology, applied in the field of wood dyeing, can solve the problems of high equipment requirements, unstable color, high loss, etc., and achieve the effects of non-toxic production process, easy dyeing treatment, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

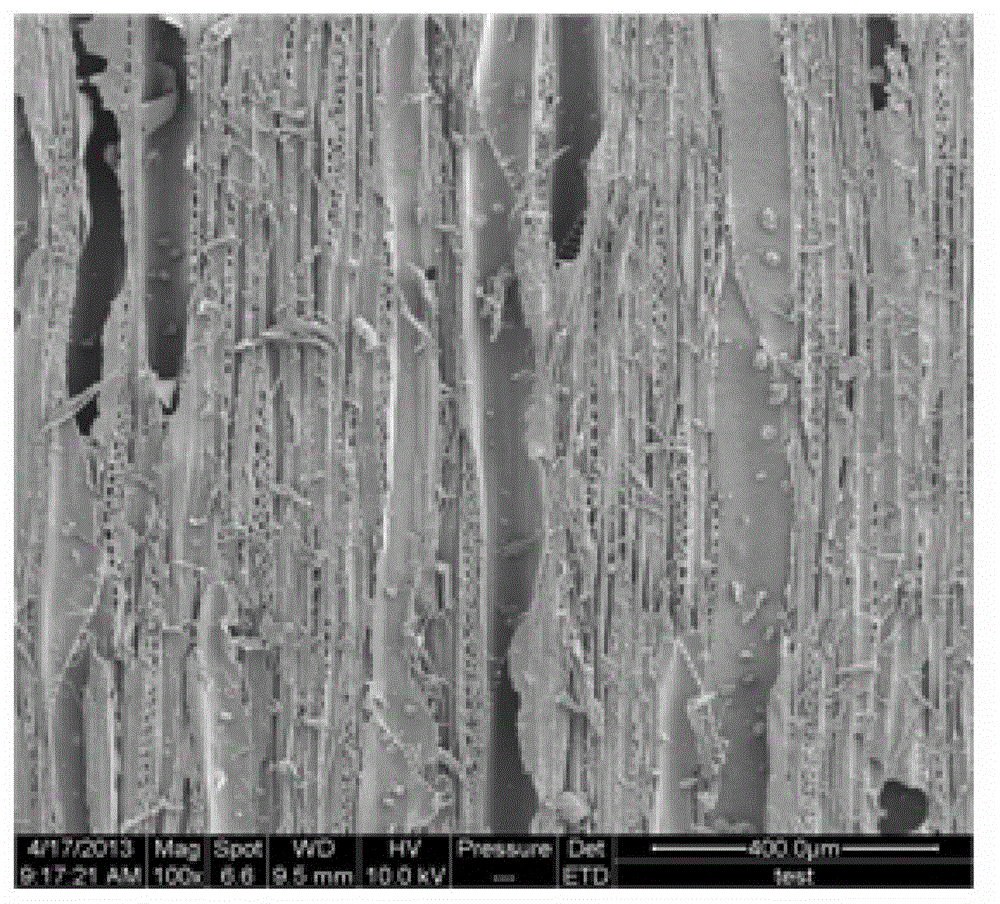

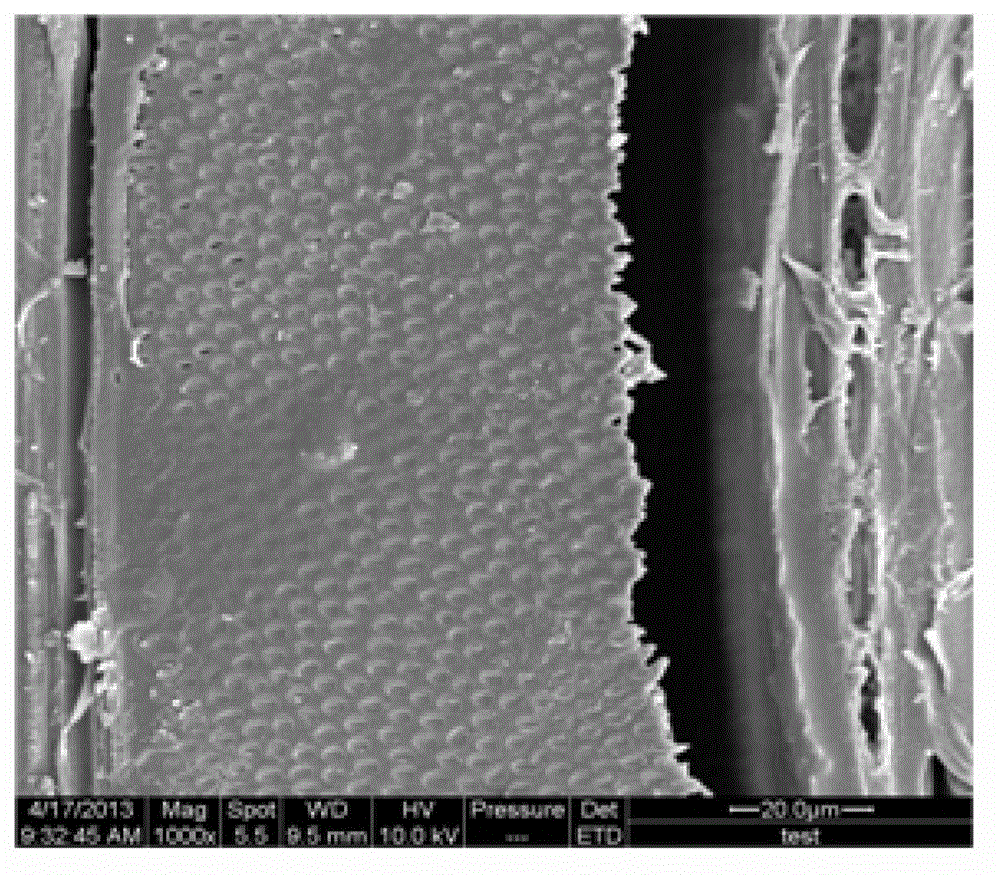

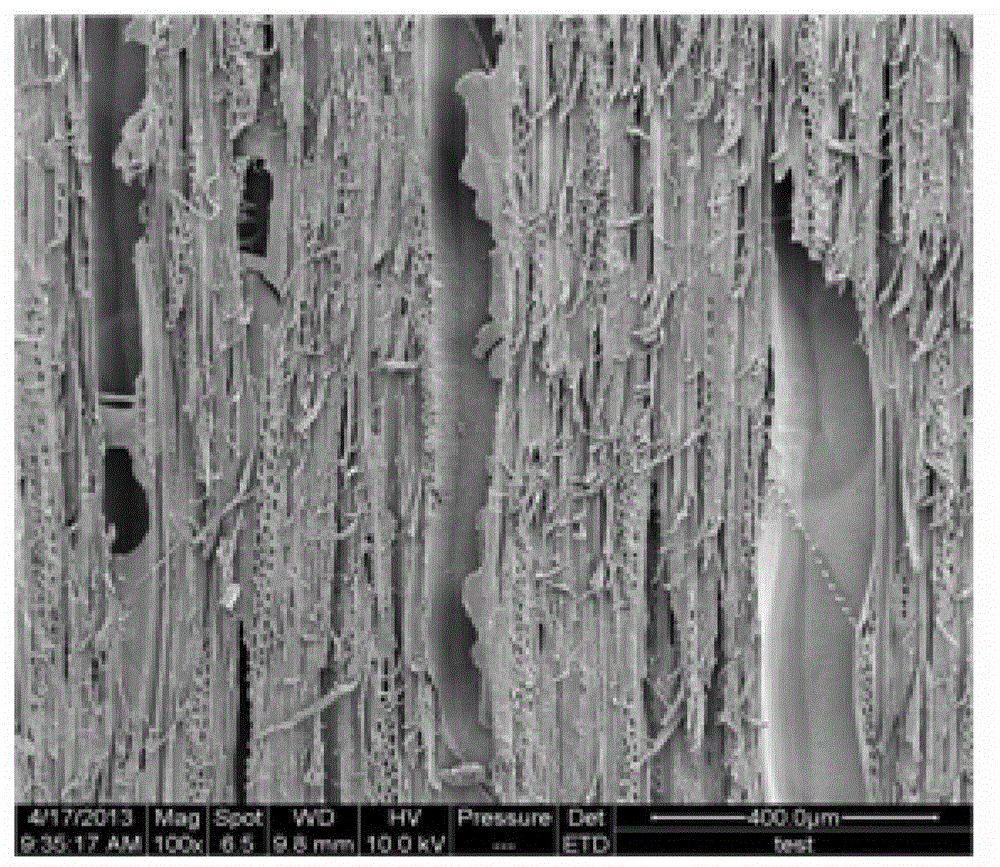

Image

Examples

specific Embodiment approach 1

[0041] Specific embodiment one: a kind of environment-friendly wood veneer staining agent of this embodiment, it is made up of iron red solution or iron yellow solution, wherein, described iron yellow solution concentration is 20~60g / L, and described The concentration of iron red solution is 10-50g / L.

[0042] The environment-friendly wood veneer stain of this embodiment is suitable for the staining of all woods.

[0043] In this embodiment, wood veneers are dyed with water-insoluble iron red and iron yellow pigments, which has the advantages of non-toxic production process, environmental protection, non-fading products, and hydrophobicity. In addition, the product is used outdoors, and the pigment is not easy to be lost in the rain, which is friendly to the environment.

[0044] In this embodiment, the water fastness of the two pigments after being treated with iron yellow and iron red is extremely high.

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that: the concentration of the iron yellow solution is 40-60 g / L, and the concentration of the iron red solution is 30-50 g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the concentration of the iron yellow solution is 50 g / L, and the concentration of the iron red solution is 40 g / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com