Energy-saving sandwich composite renewable brick wall with self-bonding bricks and building method thereof.

A technology of composite regeneration and brick walls, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of easy-to-corrosion thermal bridge effect, etc., achieve the effect of uniform force transmission and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

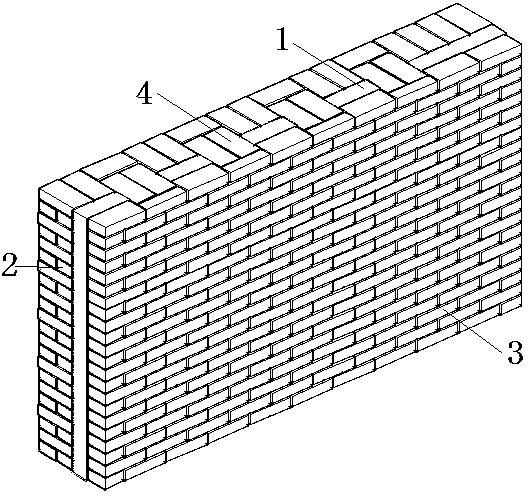

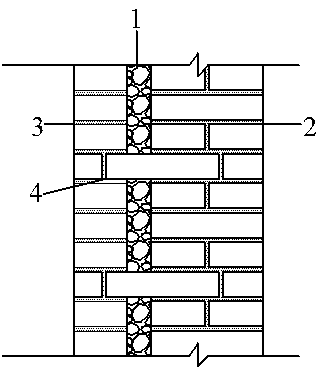

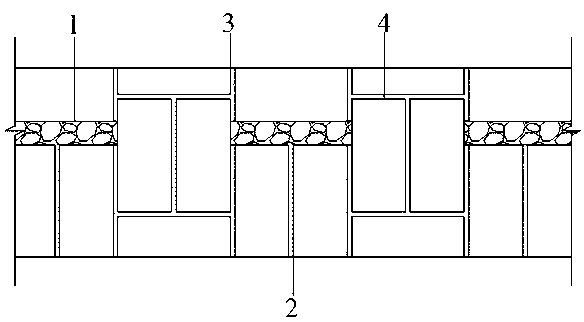

[0029] Such as Figure 1 to Figure 5 As shown, a kind of energy-saving sandwich composite wall with brick self-tie of the present invention includes inner leaf wall 2, outer leaf wall 3, and interlayer, and also includes tie brick 4; said inner leaf wall 2 includes tie bars and thickness It is a recycled brick masonry wall of 240mm; the outer leaf wall 3 refers to a 120mm thick recycled brick wall; the tie brick 4 refers to a tie between the inner leaf wall 2 and the outer leaf wall 3 Bricks; the thickness of the masonry wall of the inner leaf wall 2 is 240mm, and the masonry form is one straight and one small, that is, one skin brick is alternately carried out according to the mode of one skin brick and one skin brick; the outer leaf wall 3 The thickness of the masonry wall is 120mm, and the masonry form is the all-cis-style masonry method; the tie reinforcements are 2 φ6mm tie reinforcements for every 500mm along the wall height, and the depth of each side extending into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com