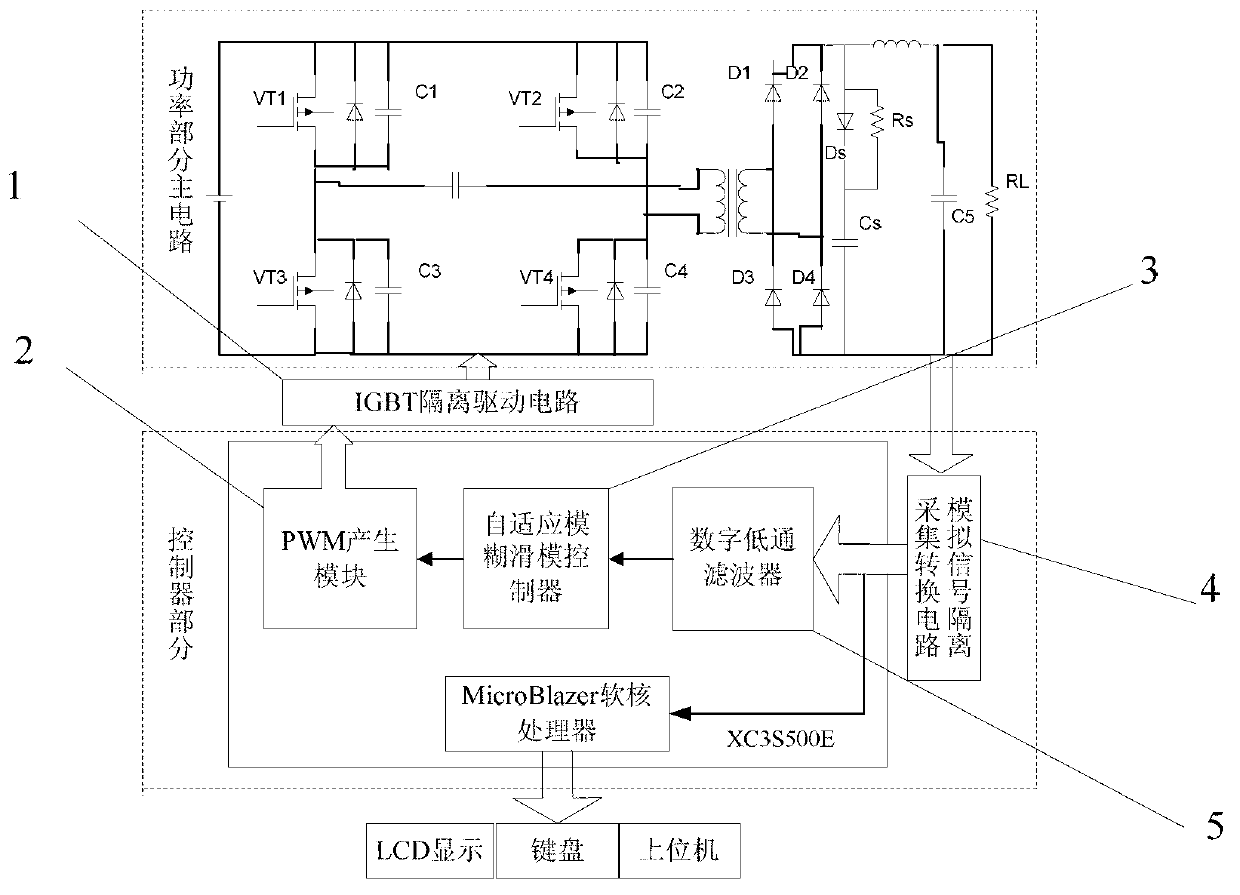

Control system of high frequency switching power supply for Cz silicon single crystal furnace and control method

A high-frequency switching power supply and control system technology, applied in control/regulation systems, electrical components, and adjustment of electrical variables, can solve problems such as power output power fluctuations, affecting single crystal quality, and poor dynamic characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

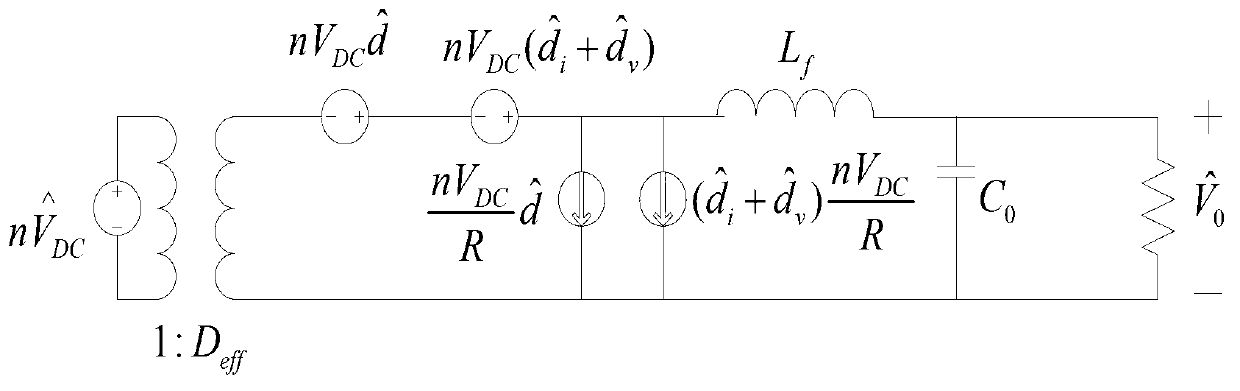

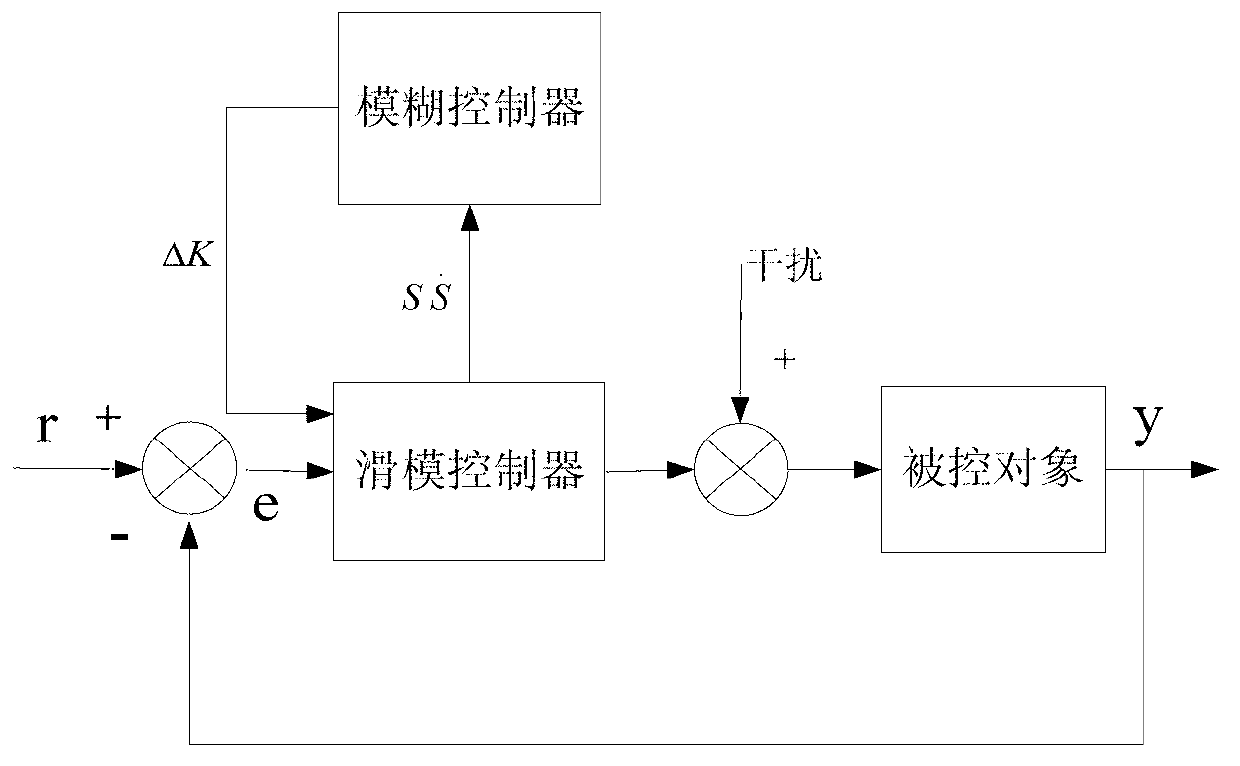

Method used

Image

Examples

Embodiment

[0163] In order to verify the effect of the above adaptive fuzzy sliding mode controller, for the TDR-100 type single crystal furnace with a full-bridge inverter high-frequency switching power supply, the parameters are selected as follows: the switching function is Among them, c=4.5 and q=50 in the control rate. Power input voltage V = 380V, switching frequency f = 20kHz. The resistance of the load is 5Ω, and the load inductance is 1mH.

[0164] Figure 6 It is the graph comparing the results of adaptive fuzzy sliding mode control and sliding mode control when the voltage setting value is 60V. Among them, the upper figure is the result of fuzzy sliding mode control, and the lower figure is the result of sliding mode control. It can be seen from the figure that the time for the adaptive fuzzy sliding mode control to reach stability is 0.005s, and the time for the sliding mode control to reach stability is 0.015s, and it is obvious that the sliding mode control has serious ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com