Glass substrate-use coating with ceramic imitation effect and coating method thereof

A technology of glass substrate and imitation porcelain, which is applied in the direction of epoxy resin coating, polyurea/polyurethane coating, coating, etc., can solve the problems of long curing time of PU paint, high toxicity of TDI, harmful to human body, etc., and achieve good imitation porcelain Effect, high curing efficiency, low content of toxic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

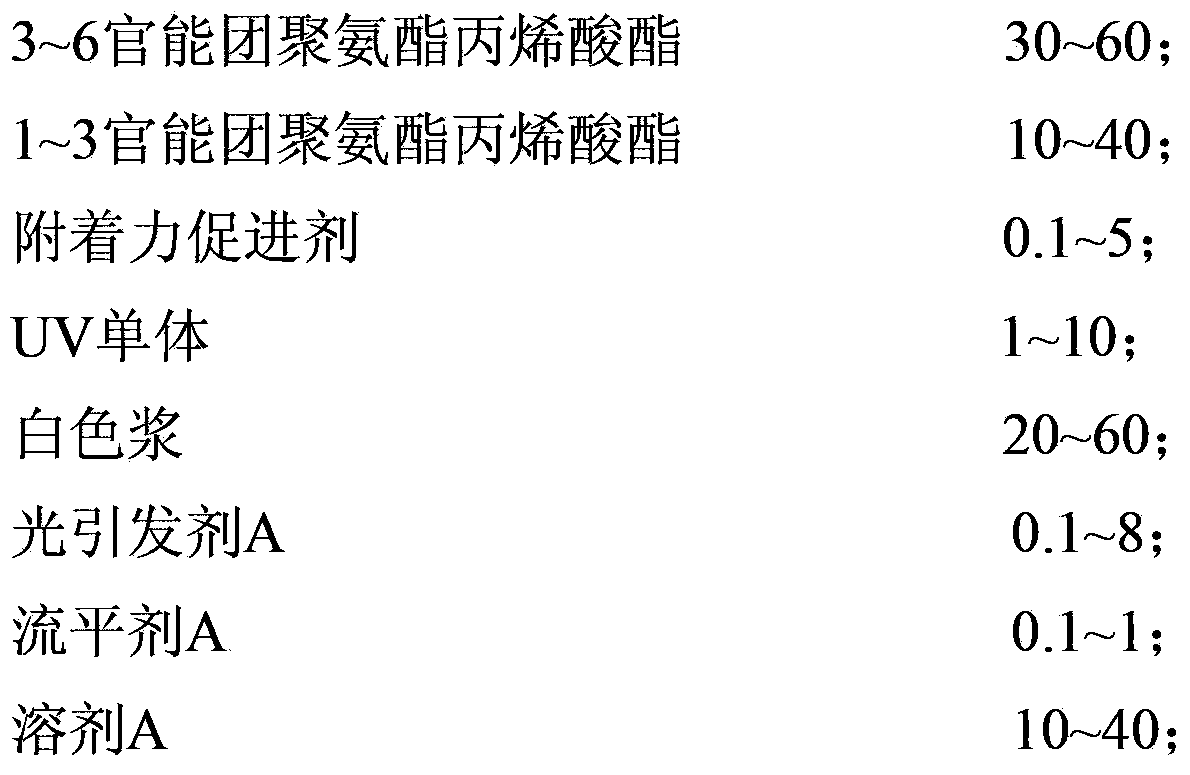

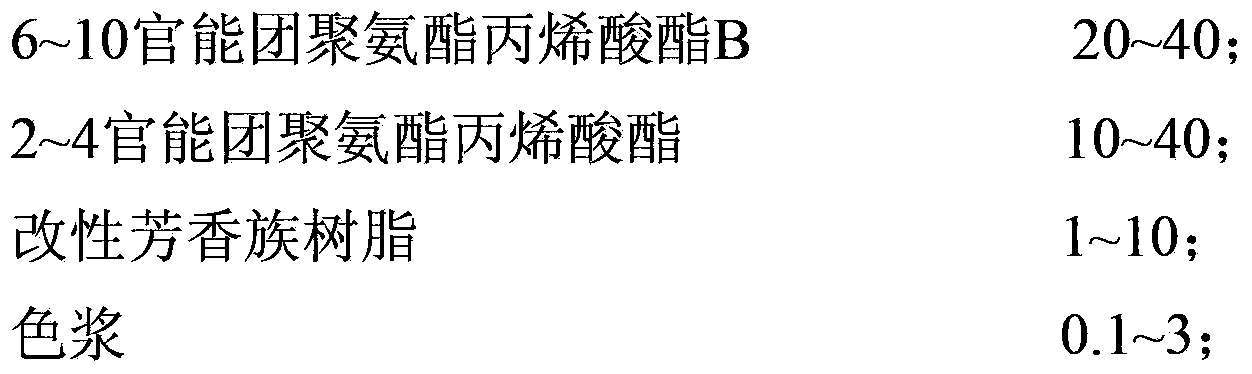

Method used

Image

Examples

Embodiment 1

[0074] The performance tests of Example 1 and Example 2 are shown in Table 4.

[0075] Table 4

[0076]

Embodiment 3

[0077] The performance tests of Embodiment 3 and Embodiment 4 are shown in Table 5.

[0078] table 5

[0079]

[0080]

Embodiment 5

[0081] The performance tests of Embodiment 5 and Embodiment 6 are shown in Table 6.

[0082] Table 6

[0083]

[0084] The test methods in Table 4, Table 5 and Table 6 are respectively:

[0085] 1. Adhesion: 100-grid method, use 3M's 600 adhesive tape to repeatedly stick and pull 3 times.

[0086] 2. Abrasion resistance: use RCA paper tape abrasion tester to test.

[0087] 3. Hardness: Tested with a Mitsubishi pencil.

[0088] 4. Ethanol resistance: Soak in 98% ethanol at room temperature for 24 hours.

[0089] 5. Salt water resistance: Soak in 5% salt water at room temperature for 48 hours.

[0090] 6. Small particles, leveling and appearance are all visually inspected.

[0091] The coating method of coating provided by the invention is as follows:

[0092] (1) Spray the primer on the glass substrate, bake it at 40-60°C for 2-5 minutes, and cure it with ultraviolet light to obtain the primer layer. The energy distribution during UV curing is 600-900mj / cm 2 ;

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com