Gate driven by cam structure

A technology of cams and turnstiles, which is applied in the field of turnstiles driven by cam structures, can solve the problems of affecting the service life of the mechanism, high equipment cost, and difficulty in speed control, so as to reduce equipment costs, keep the position unchanged, and prevent pedestrians from entering the turnstile Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

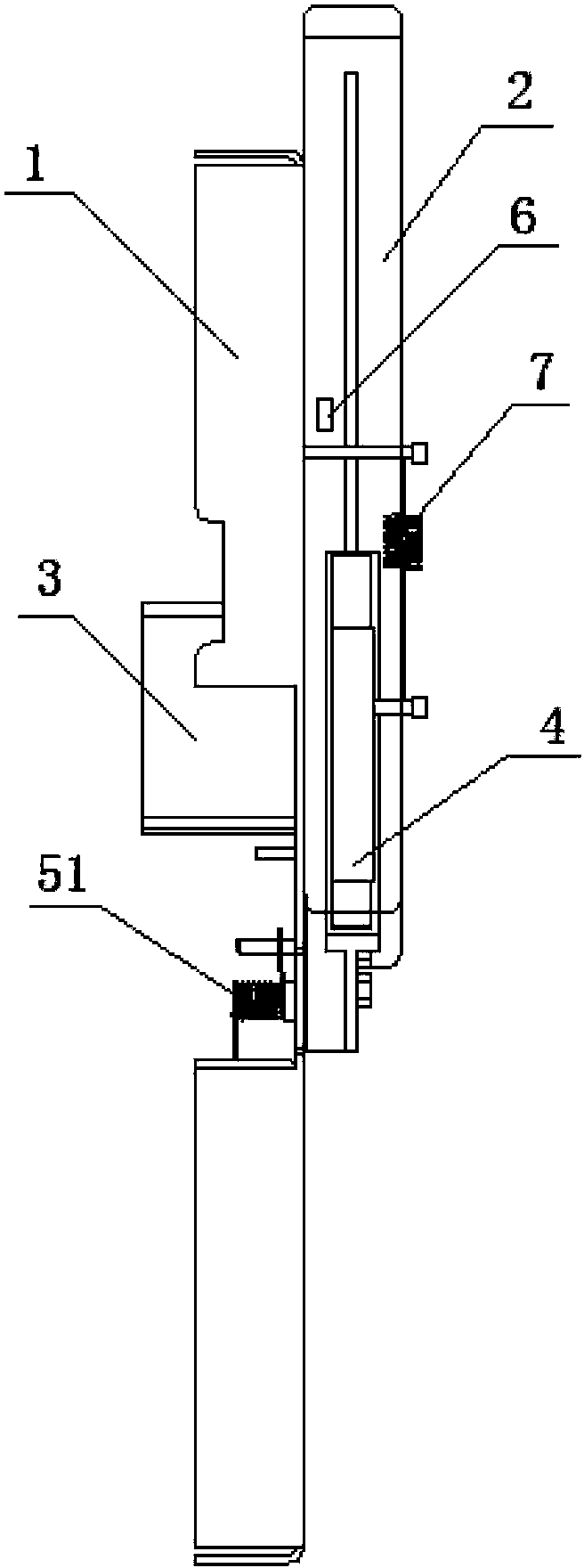

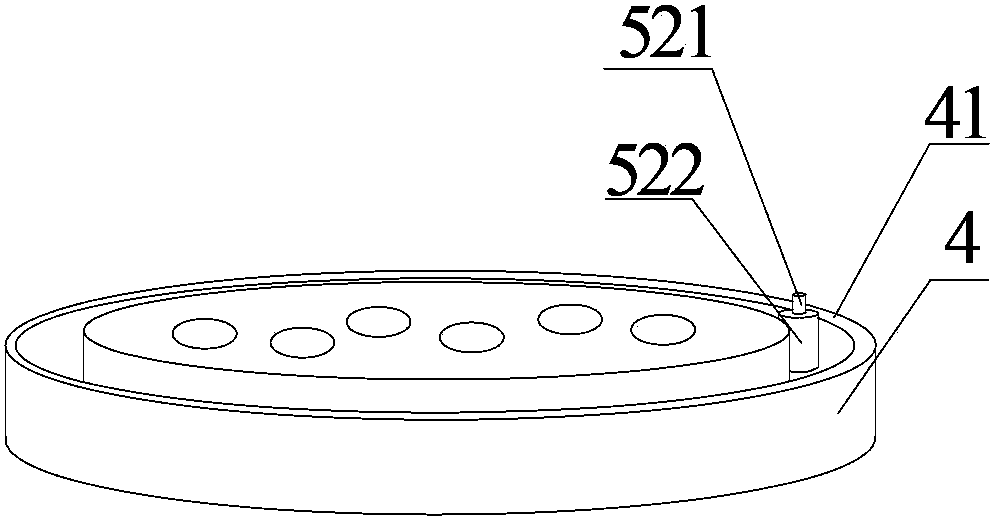

Method used

Image

Examples

Embodiment 1

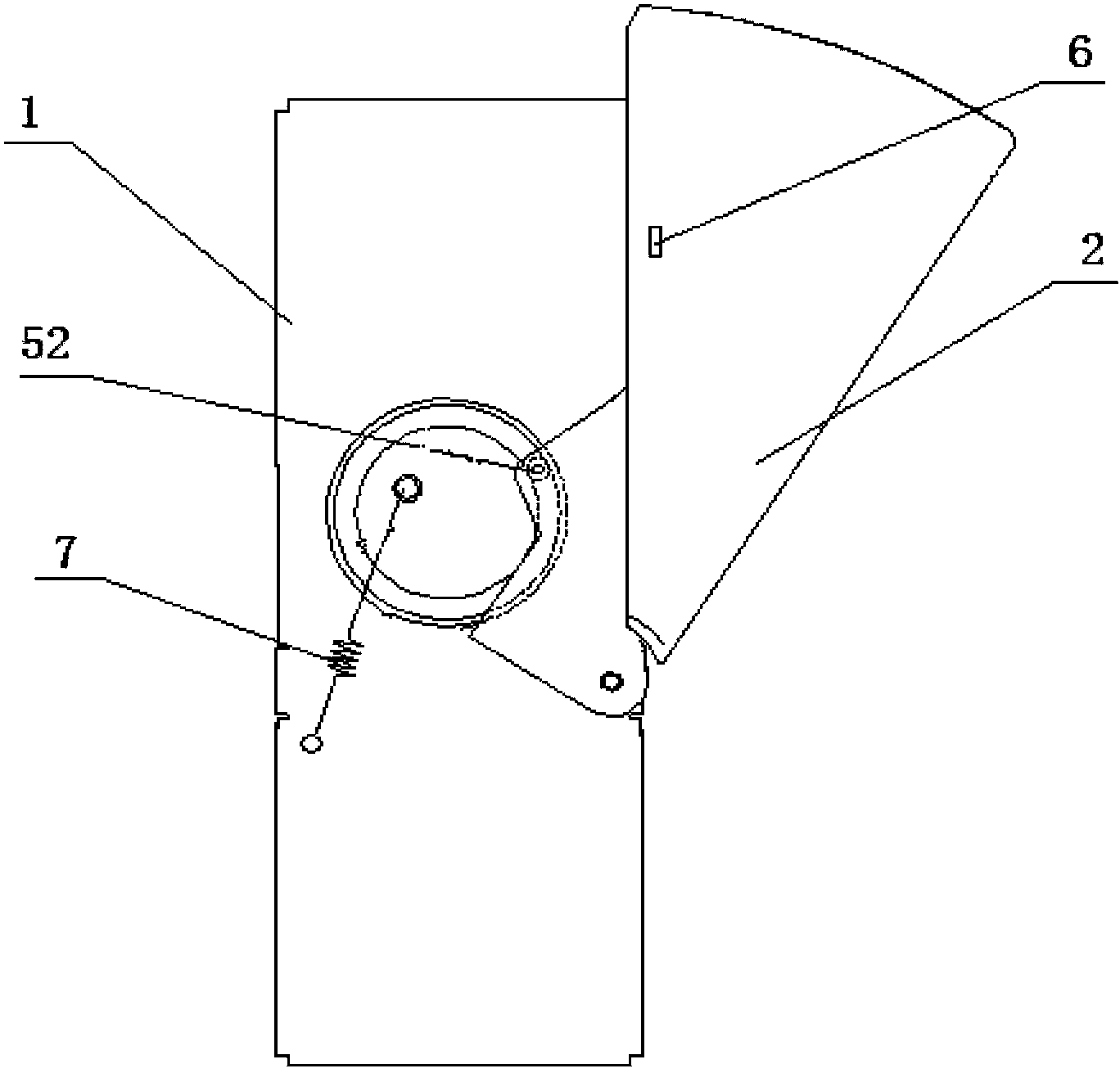

[0041] Such as Figure 5-6 As shown, the position sensor includes a photoelectric encoder 61, and the photoelectric encoder 61 includes a photoelectric code disc. The photoelectric code disc is set on the hinged end of the door panel 2 and the frame 1 and rotates with the opening and closing of the door panel 2. . The control unit presets the angle that the door panel 2 turns when the door is opened and closed, detects the real-time turned angle of the door panel 2 through the photoelectric code disc, and sends the detected angle information of the door panel 2 to the control unit. If the cam 4 is worn out, the door panel 2 cannot reach the preset angle of the door opening and closing state, and the motor 3 drives the cam 4 to rotate and continue to rotate until the control unit receives the signal that the door panel 2 switch is in place and stops rotating, keeping the door panel 2 open and closed The door position is always in place. The photoelectric encoder 61 has high t...

Embodiment 2

[0043] Such as Figure 7-8 As shown, the position sensor 6 includes a travel switch 62, and the frame 1 is provided with two limit rods 11, and the limit rod 11 cooperates with the travel switch 62 to control the opening and closing position of the door panel 2. limit. There is a limit rod 11 at the position of door opening and door closing, and the signal of whether it is in place is sent to the control unit through the travel switch 6. When the travel switch 62 touches the limit rod 11, the travel switch 62 sends an in-position command to the control unit. The control unit sends a control command to the motor 3, and the motor 3 stops rotating. When the cam 4 wears out, the control unit cannot receive the signal that the switch of the door panel 2 is in place, and the motor 3 drives the cam 4 to continue to rotate until the control unit receives the signal that the switch of the door panel 2 is in place and stops rotating, so as to keep the door panel 2 in the open and close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com