Silver-copper-coated aluminum alloy cable

A technology for aluminum alloys and cables, applied in the direction of insulated cables, metal/alloy conductors, cables, etc., can solve problems such as large costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

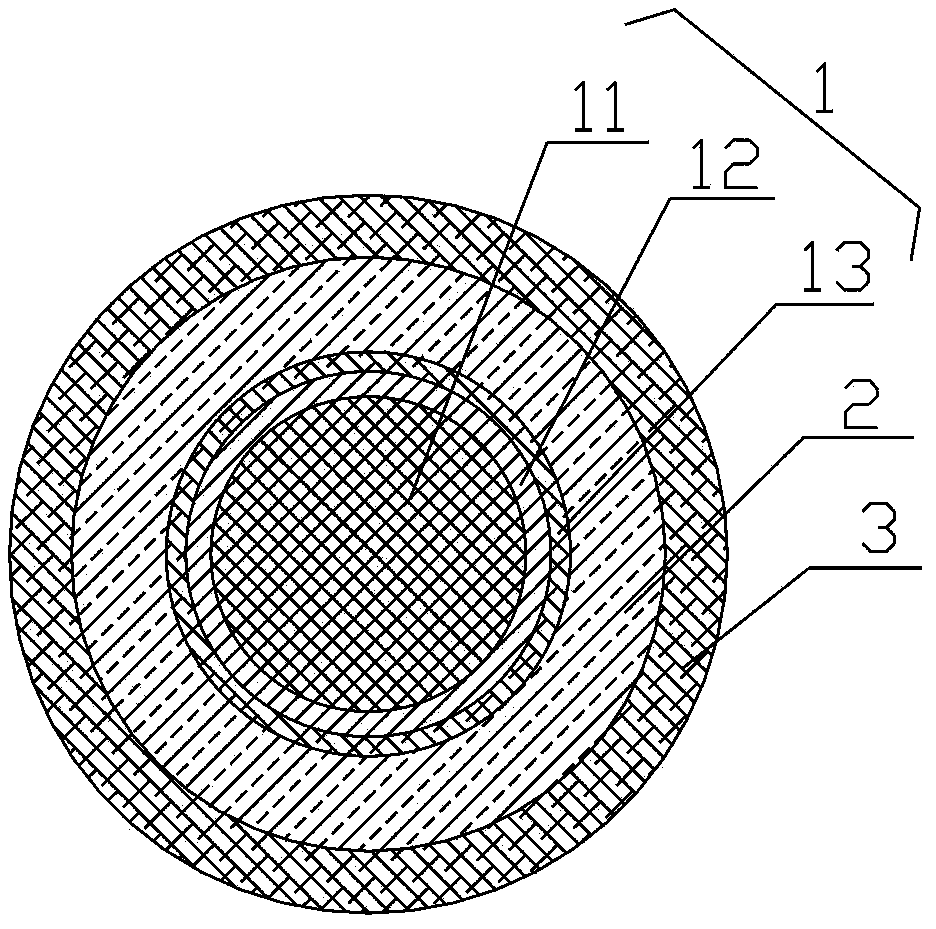

[0013] A silver-copper-clad aluminum alloy cable provided by the present invention includes a cable core 1, and the cable core 1 includes an aluminum alloy substrate 11, a copper-plated layer 12 and a silver-plated layer 13, wherein the aluminum alloy substrate 11 includes the following mass percentage of alloy elements, Ni0.51%, Mg0.23%, Ag0.005%, Cu0.08%, the balance is Al and unavoidable impurities, the diameter of the aluminum alloy substrate 11 is 0.2mm; the plating The copper layer 12 is coated on the aluminum alloy substrate 11, the silver-plated layer 13 is coated on the copper-plated layer 12, the thickness of the copper-plated layer 12 is 0.08mm, and the thickness of the silver-plated layer 13 is is 0.04mm.

[0014] In this embodiment, the aluminum alloy substrate has good electrical conductivity and signal transmission performance, and is relatively light in weight, which provides convenience for cable erection or other uses; in addition, due to the coating of the c...

Embodiment 2

[0017] A silver-copper-clad aluminum alloy cable provided by the present invention includes a cable core 1, and the cable core 1 includes an aluminum alloy substrate 11, a copper-plated layer 12 and a silver-plated layer 13, wherein the aluminum alloy substrate 11 includes the following mass Percentage of alloy elements, Ni1.25%, Mg0.79%, Ag0.062%, Cu0.75%, the balance is Al and unavoidable impurities, the diameter of the aluminum alloy substrate 11 is 1.2mm; the plating The copper layer 12 is coated on the aluminum alloy substrate 11, the silver-plated layer 13 is coated on the copper-plated layer 12, the thickness of the copper-plated layer is 0.18 mm, and the thickness of the silver-plated layer is 0.08 mm. mm.

[0018] In this embodiment, the aluminum alloy substrate has good electrical conductivity and signal transmission performance, and is relatively light in weight, which provides convenience for cable erection or other uses; in addition, due to the coating of the copp...

Embodiment 3

[0021] A silver-copper-clad aluminum alloy cable provided by the present invention includes a cable core 1, and the cable core 1 includes an aluminum alloy substrate 11, a copper-plated layer 12 and a silver-plated layer 13, wherein the aluminum alloy substrate 11 includes the following mass Percent alloying elements, Ni0.88%, Mg0.61%, Ag0.040%, Cu0.19%, the balance is Al and unavoidable impurities, the diameter of the aluminum alloy substrate 11 is 2.5mm; the plating The copper layer 12 is coated on the aluminum alloy substrate 11, the silver-plated layer 13 is coated on the copper-plated layer 12, the thickness of the copper-plated layer is 0.22 mm, and the thickness of the silver-plated layer is 0.16 mm. mm.

[0022] In this embodiment, the aluminum alloy substrate has good electrical conductivity and signal transmission performance, and is relatively light in weight, which provides convenience for cable erection or other uses; in addition, due to the coating of the copper-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com