Welding device

A welding device and control device technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as taking a long time and hindering the efficiency of welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

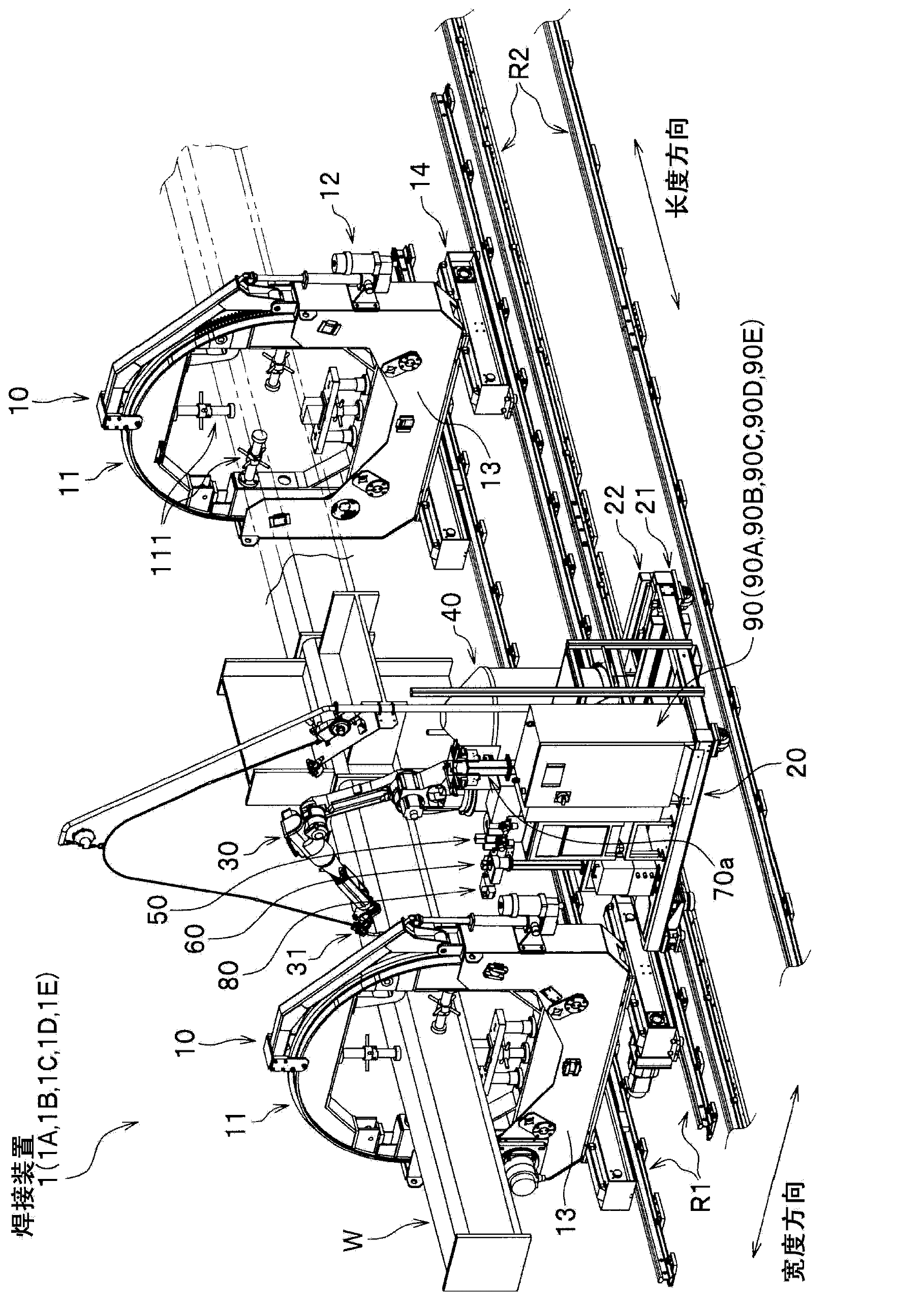

[0162] refer to Figure 1 to Figure 9 The welding device according to the first embodiment of the present invention will be described. The welding device 1 is a device for welding a steel frame structure as a workpiece for welding by, for example, gas shielded arc welding. Such as figure 1 As shown, the welding device 1 includes: a rotary positioner 10 , a trolley 20 , a welding robot 30 , a wire supply container 40 , a tip replacement device 50 , a tip cleaning device 60 , a wire cutting device 80 , and a welding control device 90 . In addition, the welding device 1 except figure 1 In addition to the shown structure, a welding slag removing device 70 is also provided (refer to Figure 6 ).

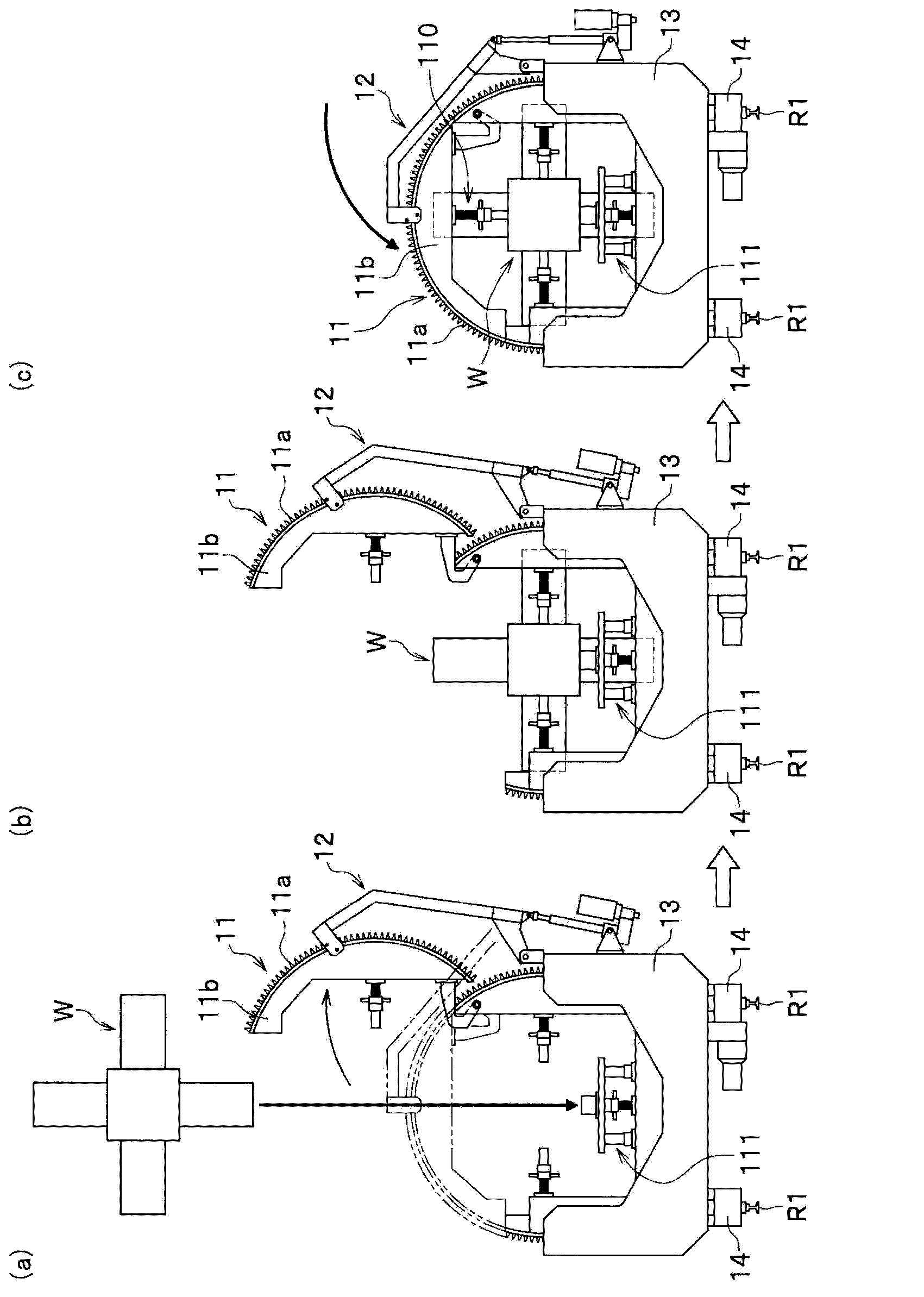

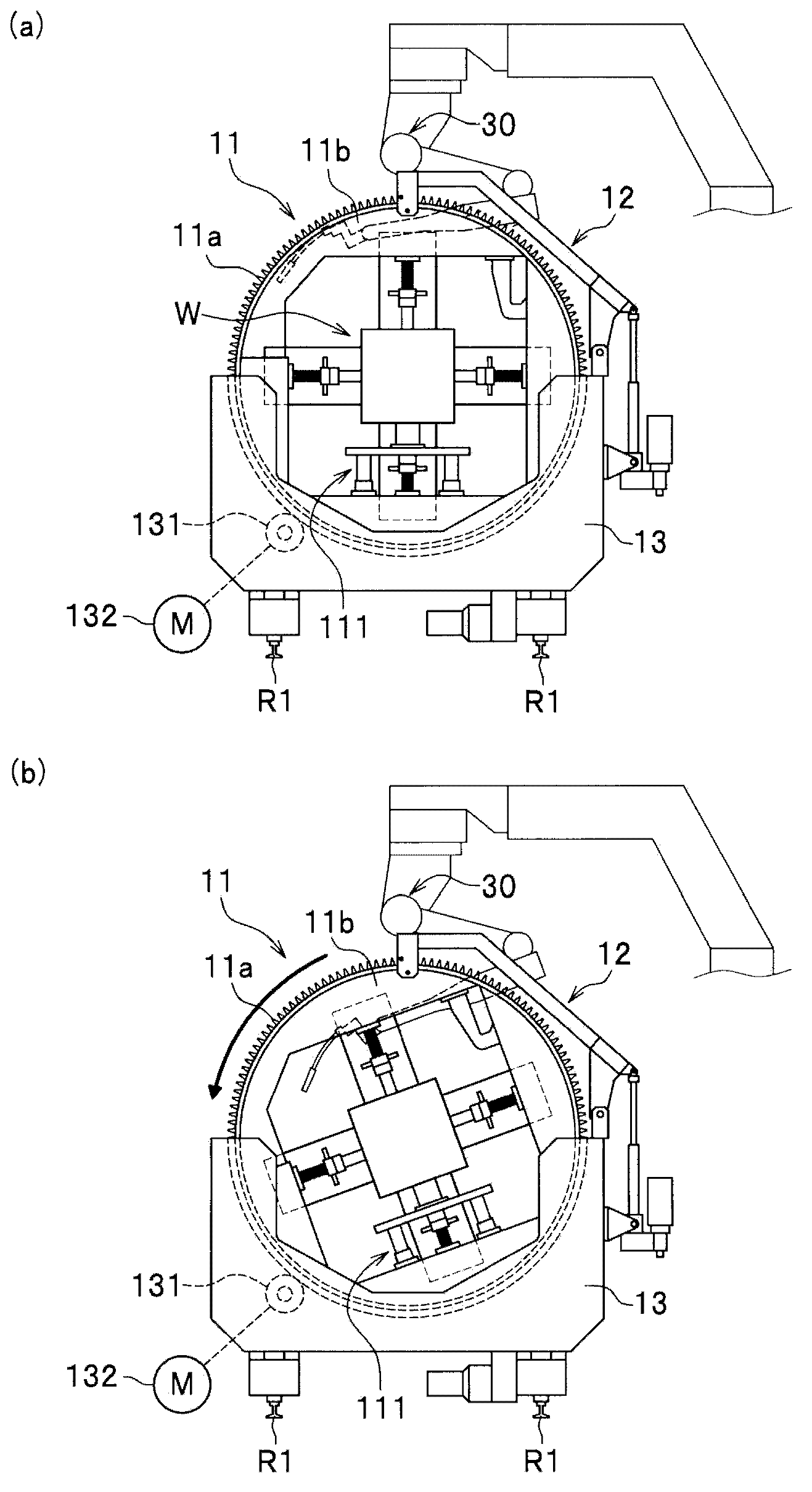

[0163] (rotary locator)

[0164] The rotation positioner 10 holds and rotates the steel structure W during welding. Such as figure 1As shown, the rotary positioner 10 is composed of a pair, and holds the columnar steel structure W at two points in the longitudinal direction of the ...

no. 2 approach

[0233] Below, refer to Figure 11 1A of welding apparatuses concerning 2nd Embodiment of this invention are demonstrated. Such as figure 1 and Figure 11 As shown, 1 A of welding apparatuses has the structure similar to the welding apparatus 1 which concerns on 1st Embodiment except having provided the welding control apparatus 90A instead of the welding control apparatus 90. Therefore, hereinafter, the description will focus on the differences from the welding device 1 , and the detailed description of the configuration overlapping with the welding device 1 and the processing procedure of the welding device 1A will be omitted.

[0234] The welding control device 90A is a device in which a function of correcting an operation program according to the eccentricity of the steel frame structure W is added to the welding control device 90 described above. Such as Figure 11 As shown, the welding control device 90A further includes a center position calculation unit 96, an eccen...

no. 3 approach

[0240] Below, refer to Figure 12 A welding device 1B according to a third embodiment of the present invention will be described. Such as figure 1 and Figure 12 As shown, the welding device 1B has the same configuration as the welding device 1 according to the first embodiment except that a welding control device 90B is provided instead of the welding control device 90 . Therefore, in the following, the description will focus on the differences from the welding device 1, and the detailed description of the configuration overlapping with the welding device 1 and the processing procedure of the welding device 1B will be omitted.

[0241] The welding control device 90B is a device in which a function of obtaining the radius of the fillet portion of the steel frame structure W through sensor detection is added to the welding control device 90 described above. Such as Figure 12 As shown, the welding control device 90B further includes a position correction unit 99 and a fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com