A kind of winding forming carbon nanotube reinforced composite material forming method

A technology for reinforcing composite materials and carbon nanotubes, which is applied in the field of composite material molding, can solve the problems of sacrificing reinforcing fibers and the overall efficiency of composite materials, low transverse strength, and limited wide application, so as to improve in-plane mechanical properties and improve mechanical properties. , the effect of good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A product with a length of 50 cm, an inner diameter of 10 cm and an outer diameter of 12 cm was prepared by the hoop winding method.

[0016] The reinforcing material used is 352 glass fiber roving. Bake it for 24 hours at 70 degrees.

[0017] Prepare an epoxy resin glue solution with a viscosity of 1.6Pa·s at room temperature, and pour the prepared glue solution into the glue tank.

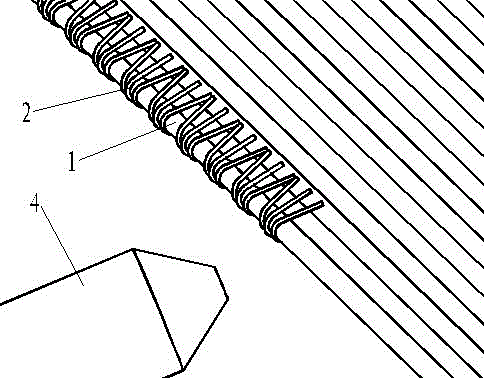

[0018] like figure 1 As shown, between the rubber groove of the winding machine and the mandrel, on one side of the dipped yarn bundle 1 and 10cm away from it, a V-3 spray gun is set, the nozzle diameter is 0.5mm, and the outlet pressure is 0.2MPa. The tank is filled with single-walled carbon nanotubes 2 with an outer diameter of about 10nm and a length of 30-100μm, mixed with acetone and TNEDIS dispersant, and subjected to ultrasonic waves with a power of 200w for 2 hours to uniformly disperse them to form 0.1mg / ml suspension.

[0019] Put the heat-treated glass fiber yarn into the wi...

Embodiment 2

[0022] A product with a length of 50 cm, an inner diameter of 10 cm and an outer diameter of 12 cm was prepared by the hoop winding method.

[0023] The reinforcing material used is 352 glass fiber roving. Bake it for 24 hours at 70 degrees.

[0024] Prepare an unsaturated polyester resin glue solution with a viscosity of 1.2 Pa·s at room temperature, and pour the prepared glue solution into the glue tank of the winding device.

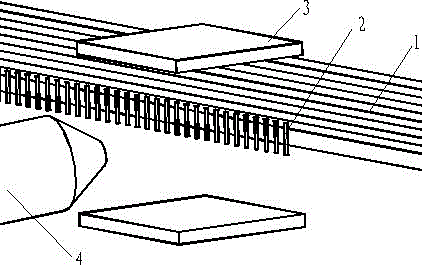

[0025] like figure 2 As shown, between the rubber groove of the winding device and the mandrel, at a distance of 15cm from one side of the dipped yarn bundle 1, a DPQ-T-95 ultrasonic spray head with a power of 10W is installed, and the storage tank connected to it is filled with external The multi-walled carbon nanotubes 2 with a diameter of about 10nm, an inner diameter of about 2nm, and a length of about 12μm are mixed with acetone and TNEDIS dispersant, and 0.1mg / ml is formed after being uniformly dispersed by ultrasonic waves with a power of 20...

Embodiment 3

[0029] A product with a length of 50 cm, an inner diameter of 10 cm and an outer diameter of 12 cm was prepared by the hoop winding method.

[0030] The reinforcing material used is 352 glass fiber roving. Bake it for 24 hours at 70 degrees.

[0031] Prepare an unsaturated polyester resin glue solution with a viscosity of 1.2 Pa·s at room temperature, and pour the prepared glue solution into the glue tank of the winding device.

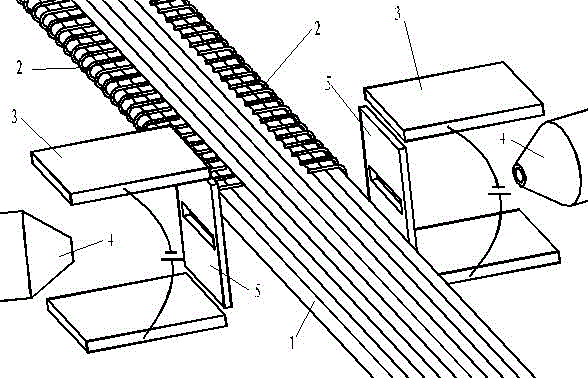

[0032] like image 3 As shown, between the rubber tank of the winding device and the mandrel, at a distance of 8cm from both sides of the dipped yarn bundle 1, a V-3 spray gun is symmetrically arranged, the nozzle diameter is 0.5mm, and the outlet pressure is 0.3MPa. The storage tank contains a suspension of single-walled carbon nanotubes 2 with an outer diameter of about 10 nm and a length of about 30-100 μm uniformly dispersed in chloroform, and the weight content of the suspension is 0.1%. An electric field device 3 is set between the ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com