Carbon fiber composite metal material needling prefabricating body and its preparation method

A technology of composite metal materials and metal material layers, applied in the direction of electric vehicles, power collectors, current collectors, etc., can solve the problems of insufficient impact resistance, insufficient impact resistance, and easy fracture of materials, and achieve good mechanical properties and durability Grinding and anti-friction performance, thermal conductivity and electrical conductivity improvement, and the effect of improving interlayer mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

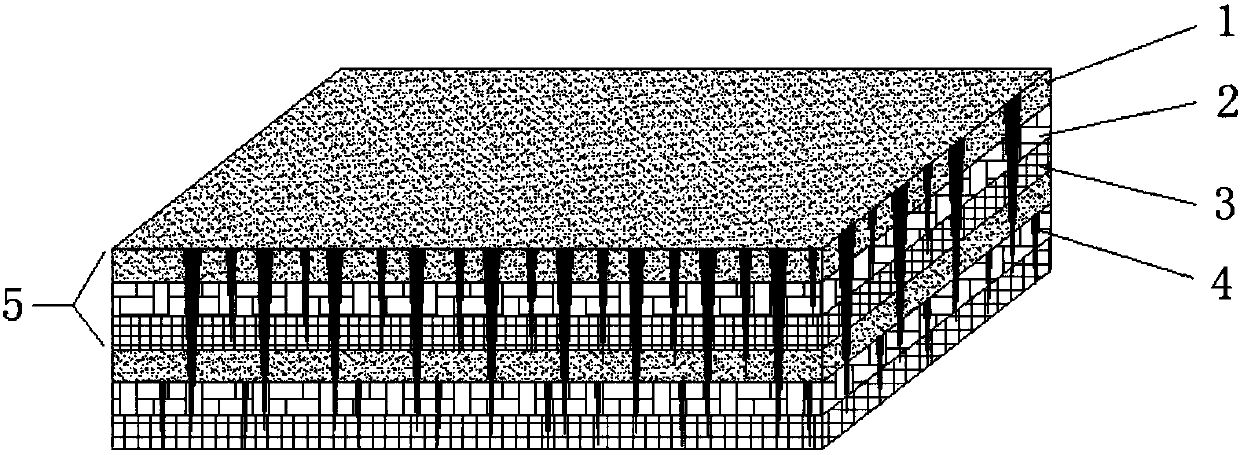

[0024] A method for preparing a carbon fiber composite metal material needle-punched prefabricated body, comprising the following steps:

[0025] (1) Preparation and molding of carbon fiber flat fabric and carbon fiber thin felt;

[0026] (2) Cutting of carbon fiber flat fabric, metal mesh, wire, and carbon fiber thin felt;

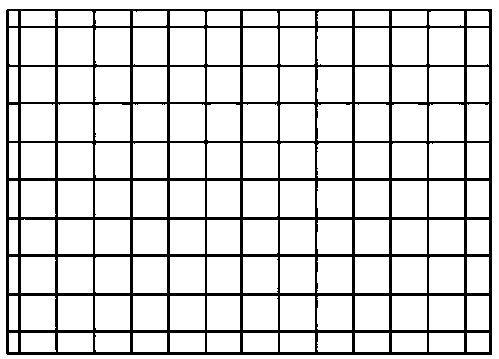

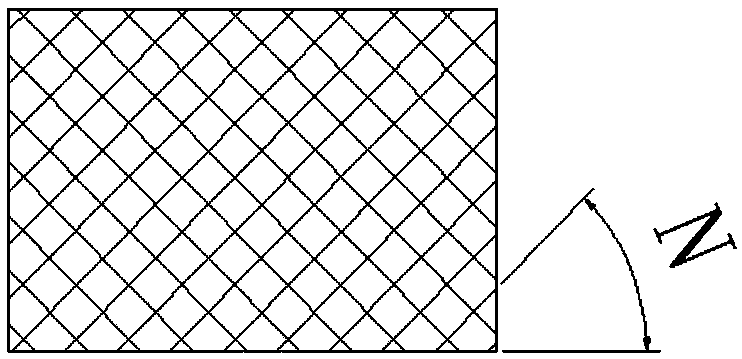

[0027] (3) Metal mesh, metal wire, carbon fiber flat fabric, and carbon fiber thin felt are sequentially laid up according to the set number of layers and angles to form a structural unit layer, and metal powder is added to the surface of the carbon fiber flat fabric;

[0028] (4) The structural unit layers are stacked multiple times, multi-angle needling forming, and the needling density is 25-50 needles / cm 2 ;Acupuncture depth of 15-20mm;

[0029] (5) Repeat steps (3) and (4) until the product thickness requirement is reached;

[0030] (6) Cutting to obtain a carbon fiber composite metal material needle-punched prefabricated body.

[0031] The prepa...

Embodiment 1

[0043] Made of 12K carbon fiber with a surface density of 100g / m 2 Carbon fiber thin felt, 3K carbon fiber made of surface density 280g / m 2 A flat two-way fabric with a diameter of 0.1mm and a copper mesh of 100 meshes. The design ratio of carbon fiber layer and copper wire mesh layer is 2:4, that is, 1 layer of carbon fiber flat fabric and 1 layer of carbon fiber thin felt combined with 4 layers of copper wire mesh. Lay 4 layers of copper wire mesh in sequence; 1 layer of carbon fiber two-way fabric; 1 layer of carbon fiber thin felt. Copper wire mesh and carbon fiber two-way fabric are laid alternately at 0° / 45° / 90° / 135° rotation angles to form a structural unit layer; the structural unit layer is needled (except for the first laying of carbon fiber thin felt layer), and the needled depth 18mm; needling density 25 needles / cm 2 , repeat stacking of structural unit layers and needling at 0° / 90° until the product design requirements are met. The size of the preform is 350mm...

Embodiment 2

[0045] Made of 6K carbon fiber with an area density of 60g / m 2 Carbon fiber thin felt, made of 6K carbon fiber, surface density 240g / m 2 A flat unidirectional fabric, a copper mesh with a diameter of 0.14mm and a mesh number of 60, and a copper powder with a particle size of 50 microns. Design the ratio of carbon fiber layer, copper wire mesh and copper powder layer in the area of 0-60mm height of the prefabricated body to be 2:5:1, that is, 1 layer of carbon fiber flat fabric and 1 layer of carbon fiber thin felt combined with 5 layers of copper wire mesh and 1 layer of copper pink. Lay 5 layers of copper mesh in sequence; 1 layer of carbon fiber unidirectional fabric; evenly spread 1 layer of copper powder, copper powder is 90g / layer; 1 layer of carbon fiber thin felt. Copper wire mesh and carbon fiber unidirectional fabric are laminated alternately at a rotation angle of 0° / 60° / 120° to form a structural unit layer; the structural unit layer is needled (except for the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Needling density | aaaaa | aaaaa |

| Acupuncture depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com