Puncture-resistant five-layer co-extrusion polyester film and preparation method thereof

A polyester film, anti-puncture technology, used in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as no research, and achieve the effect of reducing costs and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

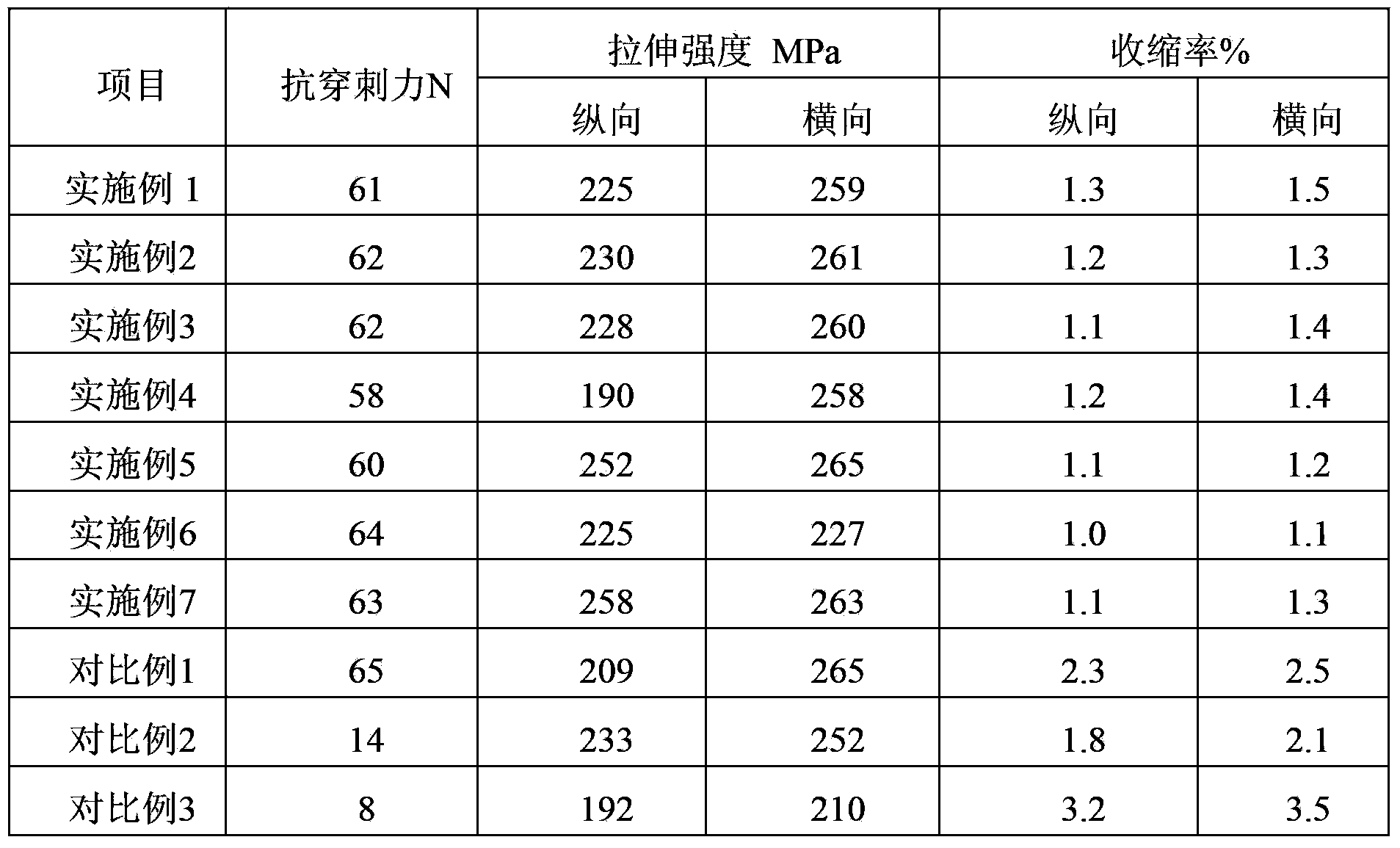

Examples

Embodiment 1

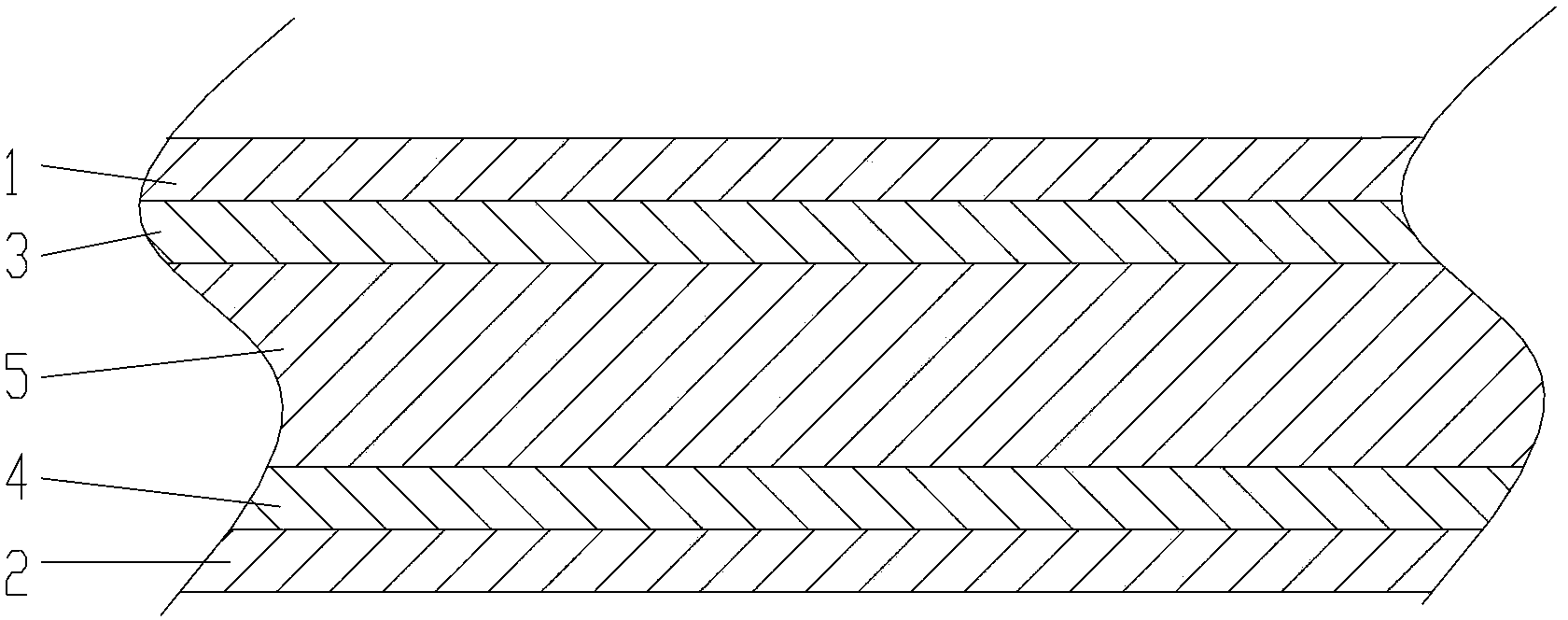

[0043] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure of a puncture-resistant five-layer co-extruded polyester film.

[0044] Raw polycaprolactam (PA6) slices for the first surface layer (70% PA6 slices and 30% PA6 anti-blocking agent masterbatch slices), raw polycaprolactam (PA6) slices for the second surface layer (70% PA6 slices and 30% PA6 anti-blocking agent masterbatch chips), the first surface layer and the second surface layer both contain at least one anti-blocking agent; the anti-blocking agent is silicon dioxide (SiO2) with a particle size of 2 μm and a content of 3000 ppm 2 ).

[0045]Raw polyester / polyamide (PET / PA6) blend for the first tie layer, raw polyester / polyamide (PET / PA6) blend for the second tie layer. Both the first connection layer and the second connection layer include the following components: PET chips, PA6 chips and polyolefin grafted maleic anhydride. The molar ratio of PET chips, PA6 chips and polyolefin graft...

Embodiment 2

[0051] Raw polycaprolactam (PA6) slices for the first surface layer (75% PA6 slices and 25% PA6 anti-blocking agent masterbatch slices), raw polycaprolactam (PA6) slices for the second surface layer (75% PA6 slices and 25% PA6 anti-blocking agent masterbatch chips), the first surface layer and the second surface layer both contain at least one anti-blocking agent; the anti-blocking agent is barium sulfate with a particle size of 3 μm and a content of 3000 ppm.

[0052] Raw polyester / polyamide (PET / PA6) blend for the first tie layer, raw polyester / polyamide (PET / PA6) blend for the second tie layer. Both the first connection layer and the second connection layer include the following components: PET chips, PA6 chips and polyolefin grafted maleic anhydride. The molar ratio of PET chips, PA6 chips and polyolefin grafted maleic anhydride is 50:50:12; polyolefin grafted maleic anhydride is polypropylene grafted maleic anhydride (PP-g-MAH); the grafting ratio 2.0%.

[0053] Send th...

Embodiment 3

[0058] Raw polycaprolactam (PA6) slices for the first surface layer (65% PA6 slices and 35% PA6 anti-blocking agent masterbatch slices), raw polycaprolactam (PA6) slices for the second surface layer (65% PA6 slices and 35% PA6 anti-blocking agent masterbatch chips), the first surface layer and the second surface layer both contain at least one anti-blocking agent; the anti-blocking agent is talcum powder with a particle size of 3.5 μm and a content of 3000 ppm.

[0059] Raw polyester / polyamide (PET / PA6) blend for the first tie layer, raw polyester / polyamide (PET / PA6) blend for the second tie layer. Both the first connection layer and the second connection layer include the following components: PET chips, PA6 chips and polyolefin grafted maleic anhydride. The molar ratio of PET chips, PA6 chips and polyolefin grafted maleic anhydride is 50:50:15; polyolefin grafted maleic anhydride is polypropylene grafted maleic anhydride (PP-g-MAH); the grafting ratio 2.2%.

[0060] Send t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com