Ink composition, image forming method, and printed article

A technology of ink composition and polymer compound, applied in the direction of ink, printing, printed matter, etc., can solve the problems of high operating cost, expensive manufacturing cost, complex system, etc., and achieve excellent water resistance and solvent resistance, and excellent adhesion , Good effect of high temperature adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0317] The phase inversion emulsification method is mentioned as a preparation method of the aqueous dispersion of a self-dispersible polymer. As the phase-inverting emulsification method, for example, the method of dissolving or dispersing the self-dispersing polymer in a solvent (such as a hydrophilic organic solvent, etc.), and directly throwing it into water without adding a surfactant , stirring and mixing in a state in which the base-generating groups (for example, acidic groups) of the self-dispersing polymer are neutralized, and removing the solvent to obtain the aqueous dispersion in the dispersed state.

[0318] The dispersed state of the particles of the self-dispersing polymer refers to the following state: a solution in which 30 g of the water-insoluble polymer is dissolved in 70 g of an organic solvent (such as methyl ethyl ketone), an alkali capable of 100% neutralizing the water-insoluble polymer Mix and stir the neutralizing agent of the generating group (sodi...

Embodiment 1~23、 Embodiment 39~66、 comparative example 1~3、 comparative example 7~11

[0426] [Preparation of ink composition]

[0427]Dispersions of (a) specific copolymers or comparative polymers, (b) water, (c) water-soluble organic solvents, (d) pigments (colorants) and surfactants in accordance with the following Tables 4, 6 and 7, using a mixer (L4R manufactured by SILVERSON Co., Ltd.) at 250 rpm (Examples 1-23, Comparative Examples 1-3) or 500 rpm (Examples 39-66, Comparative Examples 7-3) 11) Mixing and stirring were carried out to prepare rough ink compositions respectively.

[0428] The resulting crude ink compositions were placed in plastic disposable syringes and filtered through a polyvinylidene fluoride (PVDF) filter with a pore size of 5 μm (Millex-SV manufactured by Millipore, with a diameter of 25 mm) to obtain Ink compositions of Examples 1 to 23, Examples 39 to 66, Comparative Examples 1 to 3, and Comparative Examples 7 to 11 as finished products.

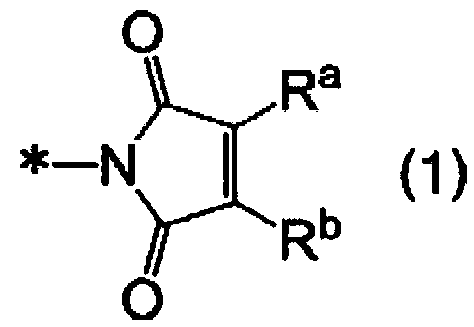

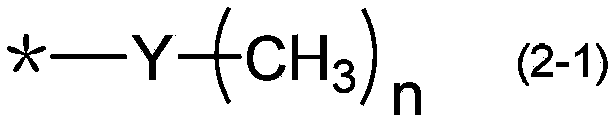

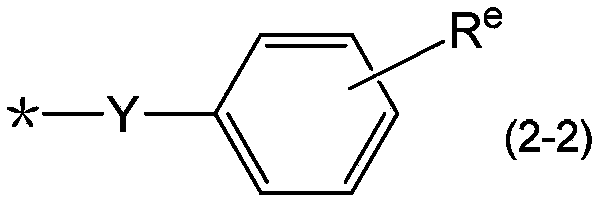

[0429] Among them, the (a) specific copolymers of the present invention (compounds A-1 to A-4...

Synthetic example 1

[0431] [Synthesis Example 1: (a) Synthesis of Specific Copolymers A-1, A-3, A-5, A-8 and A-11]

[0432]

[0433] 75 g of toluene and 42.0 g of dimethylmaleic anhydride (manufactured by Sigma-Aldrich Japan Co., Ltd.) were introduced into a 500 ml three-neck flask equipped with a Dean-Stark distillation tube, while using a stirrer (Shinto Scientific Co., Ltd.: Three-one Motor ) was heated while stirring, and the temperature was raised to 50°C. 25.0 g of 3-amino-1-propanol was added dropwise over 30 minutes, followed by stirring for 4 hours. After cooling down to 60°C, 0.042 g of p-methoxyphenol (manufactured by Wako Pure Chemical Industries, Ltd.) and 6.2 g of sulfuric acid (manufactured by Wako Pure Chemical Industries, Ltd.) were added, and methacrylic acid (manufactured by Wako Pure Chemical Industries, Ltd.) was added dropwise over 30 minutes. Junyaku Industry Co., Ltd.) 43.0 g. After the dropwise addition, the temperature was raised to reflux of the solvent, and the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com