A rotating film bubble electrospinning device

A technology of bubble electrospinning and spinning film, applied in the field of spinning equipment, can solve the problems of easy clogging of needles, large performance impact, and inability to industrialize production, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

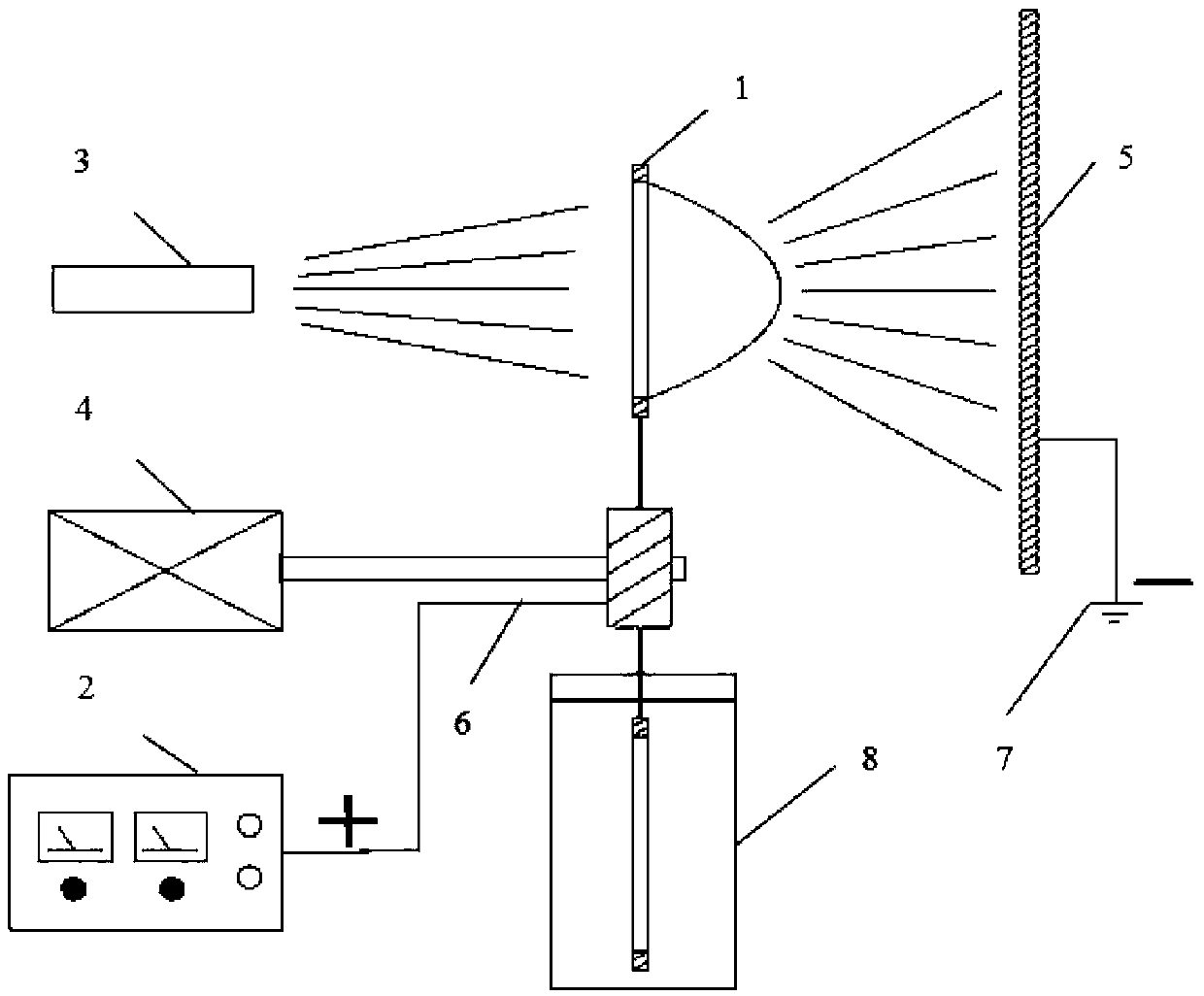

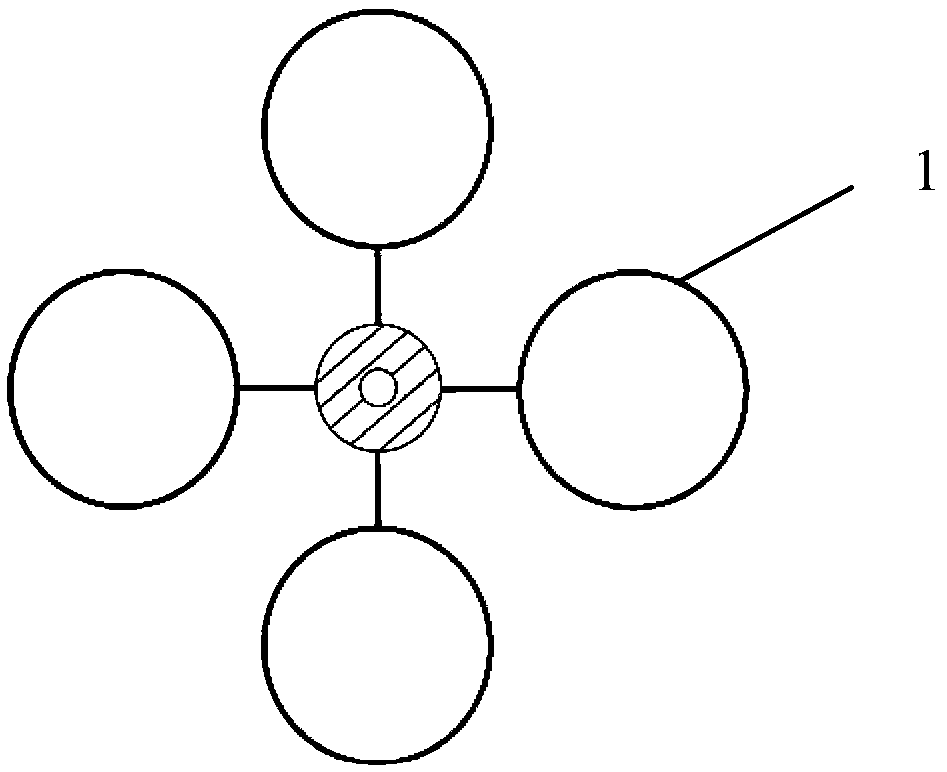

[0035] like figure 1 As shown, the present invention discloses a rotating film bubble electrospinning device, including a film bubble generator 1, a high-voltage electrostatic generator 2, a fan 3, a receiver 5, a motor 4, a liquid storage tank 8, a metal positive electrode 6 and The ground electrode 7, the thin film bubble generator 1 is arranged between the fan 3 and the receiver 5, the fan 3 is placed behind the thin film bubble generator 1, the receiver 5 is arranged directly in front of the thin film bubble generator 1, and the receiver 5 is used for Receiving the jet emitted by the thin film bubble generator 1, the thin film bubble generator 1 is connected with the high-voltage electrostatic generator 2 and the motor 4, and the motor 4 drives the thin film bubble generator 1 to rotate, and the liquid storage tank 8 is arranged on the thin film bubble generator 1 is used to provide solution to the thin film bubble generator 1, the metal positive electrode 6 and the ground...

Embodiment 2

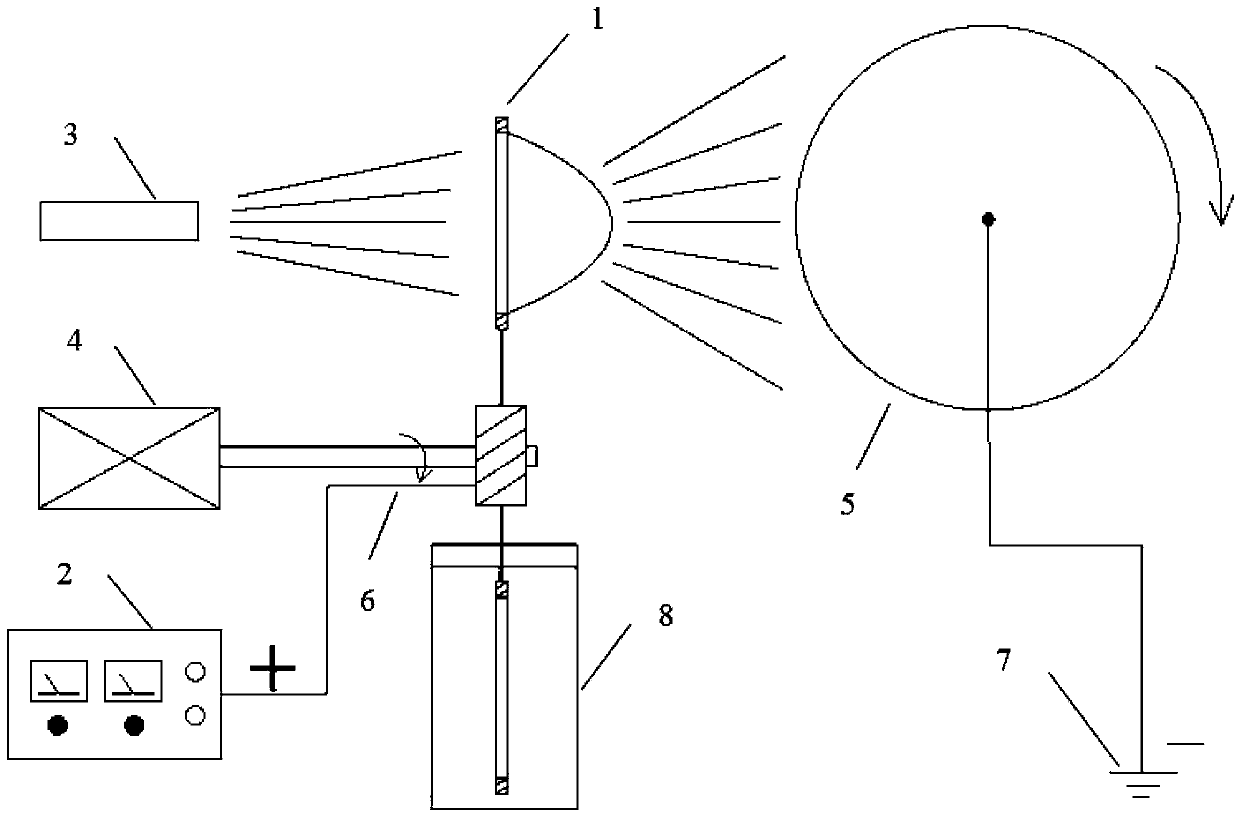

[0045] like image 3 As shown, the present invention discloses a rotating film bubble electrospinning device, including a film bubble generator 1, a high-voltage electrostatic generator 2, a fan 3, a receiver 5, a motor 4, a liquid storage tank 8, a metal positive electrode 6 and The ground electrode 7, the thin film bubble generator 1 is arranged between the fan 3 and the receiver 5, the fan 3 is placed behind the thin film bubble generator 1, the receiver 5 is arranged directly in front of the thin film bubble generator 1, and the receiver 5 is used for Receiving the jet emitted by the thin film bubble generator 1, the thin film bubble generator 1 is connected with the high-voltage electrostatic generator 2 and the motor 4, and the motor 4 drives the thin film bubble generator 1 to rotate, and the liquid storage tank 8 is arranged on the thin film bubble generator 1 is used to provide solution to the thin film bubble generator 1, the metal positive electrode 6 and the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com