A method of stretching thinning and permanent setting of colored wool

A dyeing method and colored technology, applied in textiles and papermaking, textile material processing, continuous processing of textile materials, etc., can solve the problems of long stretching process time, weak luster, low production efficiency, etc. Related problems, simple process, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

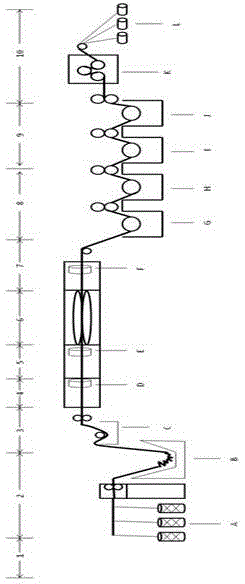

Image

Examples

Embodiment 1

[0025] A method for stretching, thinning and permanently setting navy blue wool with a fineness of 21.8um dyed with reactive dyes into navy blue wool with a fineness of 18.2um

[0026] (1) Colored wool preparation: Select navy blue wool strips with a wool fineness of 21.8um after wool dyeing with reactive dyes; (2) Carding: 11 above-mentioned navy blue wool strips each weighing 24g / m Combining, drafting and carding on the carding machine A, the drafting ratio is 3.8, to obtain a navy blue wool strip with a weight of 75g / m, and store it in the storage device B; (3) Pretreatment: the transmission wheel is 4.5m / The speed of min will import the dark blue wool strip in the storage device B into the pretreatment tank C containing the wool stretching and thinning pretreatment liquid, and the specific composition and weight percentage of the wool stretching and thinning pretreatment liquid in the tank are: Sodium pyrosulfite: 4.0%, BASF's penetrant FR-M: 0.7%, and the rest is water. ...

Embodiment 2

[0029] Method of stretching, thinning and permanently setting black wool with a fineness of 20.3um dyed by mordant dyes into black wool with a fineness of 17.4um

[0030] (1) Colored wool preparation: select black wool strips with a wool fineness of 21.8um after dyeing with mordant dyes; (2) Carding: put 11 above-mentioned black wool strips with a weight of 24g / m on the needle carding machine A Combining, drafting and carding, the drafting ratio is 3.8, and the black wool strip with a weight of 75g / m is obtained, and stored in the storage device B; (3) Pretreatment: the transmission wheel will store the wool at a speed of 4.5m / min. The black wool strip in the device B is introduced into the pretreatment tank C containing the wool stretching and thinning pretreatment liquid. The specific composition and weight percentage of the wool stretching and thinning pretreatment liquid in the tank are: sodium pyrosulfite: 4.0% , the penetrating agent produced by BASF has good points FR-M...

Embodiment 3

[0033] The gray wool with a fineness of 18.8um dyed by metal complex dyes is stretched and thinned and permanently set into a gray wool with a fineness of 16.4um

[0034](1) Colored wool preparation: select gray wool strips with a wool fineness of 21.8um after dyeing with metal complex dyes; (2) Carding: 11 above-mentioned gray wool strips with a weight of 24g / m each are combed Combining, drafting and carding on the machine A, the drafting ratio is 3.9, and the gray wool sliver with a weight of 73g / m is obtained, and stored in the storage device B; (3) Pretreatment: the transmission wheel is driven at a speed of 4.3m / min Import the gray wool strips in the storage device B into the pretreatment tank C containing the wool stretching and thinning pretreatment liquid. The specific composition and weight percentage of the wool stretching and thinning pretreatment liquid in the tank are: sodium metabisulfite: 3.8 %, the penetrating agent produced by BASF FR-M: 0.8%, the rest is wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com