Supporting device of bulb turbine unit

A technology of bulb tubular flow and support devices, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve problems affecting the safe operation of bulb tubular units, and achieve the effect of preventing left and right swing and avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

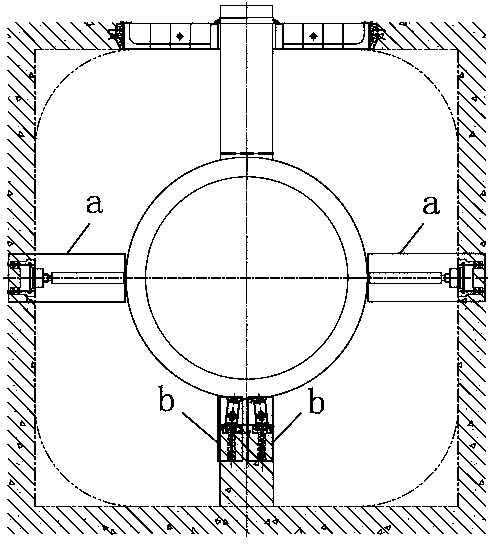

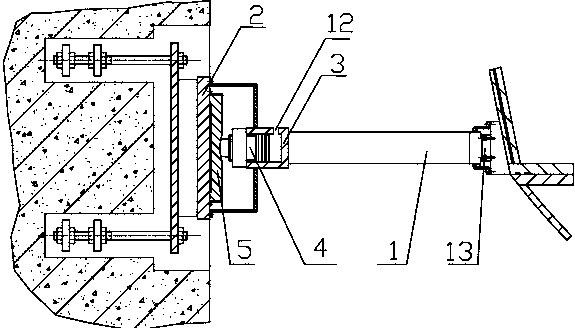

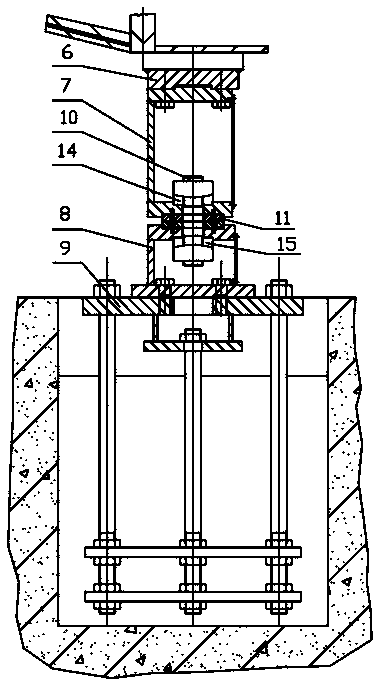

[0033] A support device for a bulb tubular unit, including a horizontal support mechanism and a vertical support mechanism, the horizontal support mechanism includes a support rod 1, a first base plate 2 connected to the foundation of the flow channel, and a piston device connected to one end of the support rod 1, the piston The device includes a piston cylinder 3 and a ball piston 4 arranged in the piston cylinder 3. The ball piston 4 is connected to the first base plate 2 through an elastic spherical support seat 5, and the other end of the support rod 1 is connected to the generator of the bulb tubular unit. There is a gap between the bulb body, the elastic spherical support seat 5 and the first base plate 2; the vertical support mechanism includes an upper support seat 6, a middle support seat 7, a lower support seat 8 and a second support seat connected to the flow channel foundation. The base plate 9, the upper support base 6 is located at the lower end of the generator b...

Embodiment 2

[0036] A support device for a bulb tubular unit, including a horizontal support mechanism and a vertical support mechanism, the horizontal support mechanism includes a support rod 1, a first base plate 2 connected to the foundation of the flow channel, and a piston device connected to one end of the support rod 1, the piston The device includes a piston cylinder 3 and a ball piston 4 arranged in the piston cylinder 3. The ball piston 4 is connected to the first base plate 2 through an elastic spherical support seat 5, and the other end of the support rod 1 is connected to the generator of the bulb tubular unit. There is a gap between the bulb body, the elastic spherical support seat 5 and the first base plate 2; the vertical support mechanism includes an upper support seat 6, a middle support seat 7, a lower support seat 8 and a second support seat connected to the flow channel foundation. The base plate 9, the upper support base 6 is located at the lower end of the generator b...

Embodiment 3

[0041] A support device for a bulb tubular unit, including a horizontal support mechanism and a vertical support mechanism, the horizontal support mechanism includes a support rod 1, a first base plate 2 connected to the foundation of the flow channel, and a piston device connected to one end of the support rod 1, the piston The device includes a piston cylinder 3 and a ball piston 4 arranged in the piston cylinder 3. The ball piston 4 is connected to the first base plate 2 through an elastic spherical support seat 5, and the other end of the support rod 1 is connected to the generator of the bulb tubular unit. There is a gap between the bulb body, the elastic spherical support seat 5 and the first base plate 2; the vertical support mechanism includes an upper support seat 6, a middle support seat 7, a lower support seat 8 and a second support seat connected to the flow channel foundation. The base plate 9, the upper support base 6 is located at the lower end of the generator b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com