Buckling plate type quasi-zero stiffness vibration isolator

A technology of quasi-zero stiffness and vibration isolators, which is applied in the direction of shock absorbers, shock absorber-spring combinations, shock absorbers, etc. Single object and other problems, to achieve the effect of reasonable structure design, optimized performance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

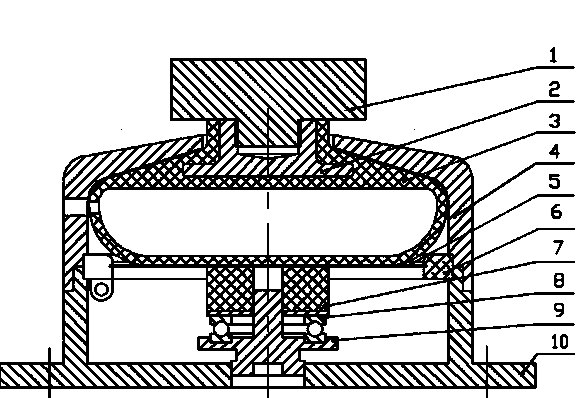

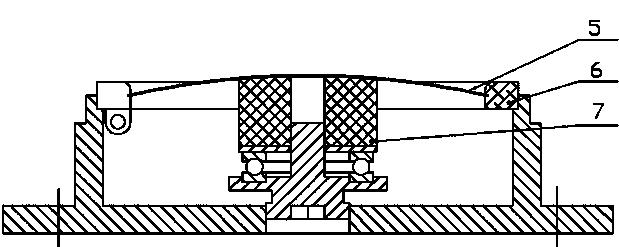

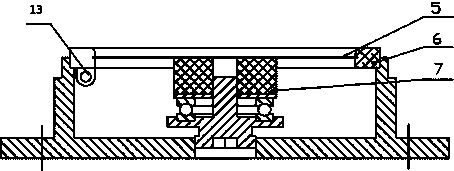

[0034] Such as Figures 1 to 4As shown, a buckling plate type quasi-zero-stiffness vibration isolator includes a base 10, an end cover 4 and a connecting piece 2, and also includes a quasi-zero-stiffness structure, which includes an elastic plate 5 with negative stiffness and a set The elastic member 7 with positive stiffness under the elastic plate 5, the elastic plate 5 is nested in an adjustment hoop 6, and the adjustment hoop 6 is fixed at the connection between the base 10 and the end cover 4, so that The elastic member 7 is supported by an adjustment mechanism 9 , and the adjustment mechanism 9 is arranged on the base 10 . The adjustment hoop 6 has a bolt tightening device 13, the adjustment hoop 6 is provided with an inward groove, the elastic plate 5 is nested in the groove of the adjustment hoop 6, and the adjustment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com