Thin-wall cylinder modal test system and method for single-point laser continuous scanning vibration test

A thin-walled cylinder, modal testing technology, used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of incoherent vibration, inability to keep up, difficult to ensure the accuracy of measurement, etc., to achieve high measurement accuracy , to ensure the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

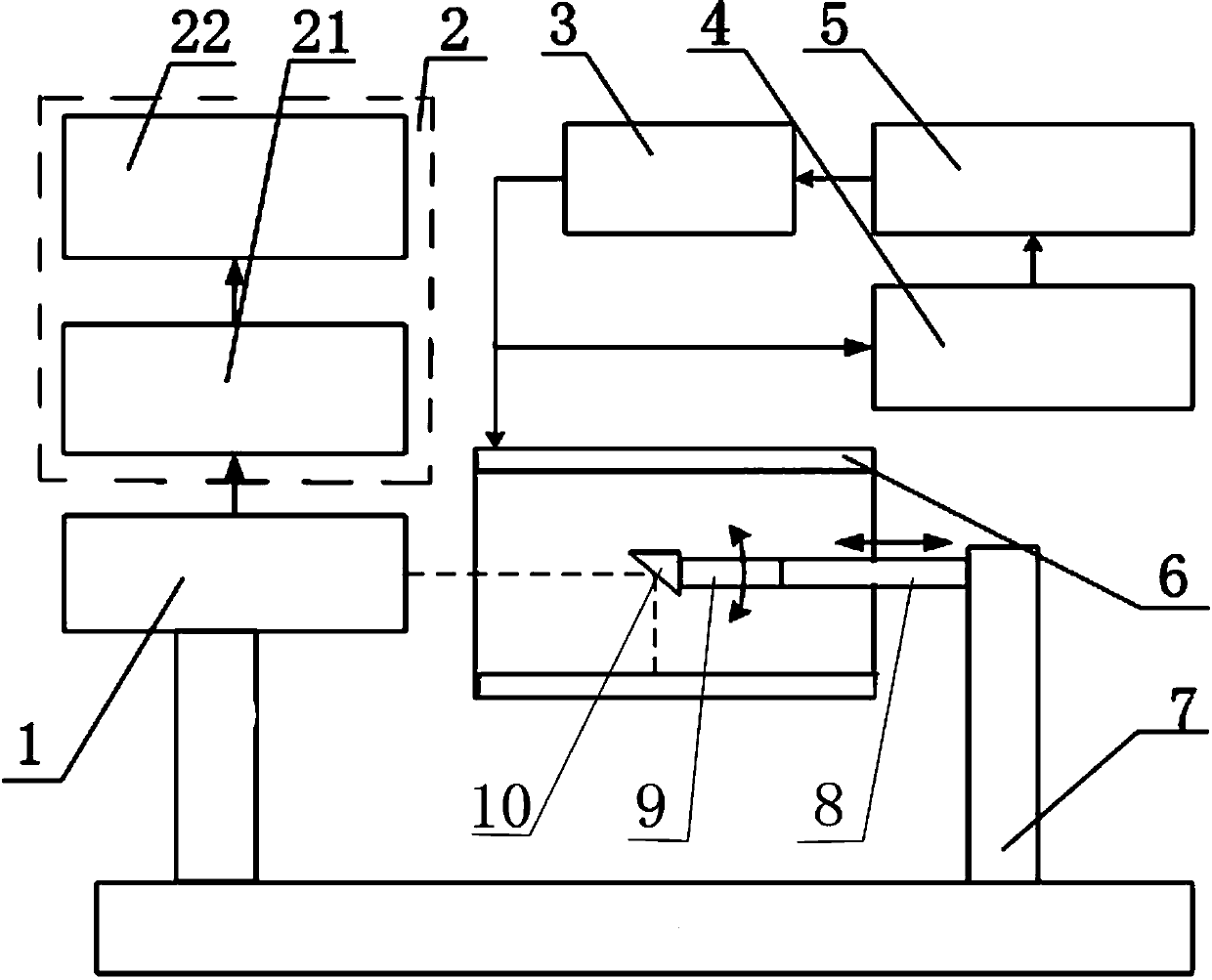

[0021] like figure 1 As shown, the thin-walled cylinder modal test system for single-point laser continuous scanning vibration measurement of the present invention includes a thin-walled cylinder 6, a laser vibrometer 1, a rectangular prism 10 at an angle of 45 degrees, a rotary motion control system 9, and a linear motion control system 8. The exciter 3 and the data acquisition system 2; the thin-walled cylinder 6 is suspended on the support 7 by a flexible rope, and the inclined plane of the rectangular prism 10 at an angle of 45 degrees is installed on the thin-walled cylinder at an angle of 45 degrees to the axis of the thin-walled cylinder 6 Inside the cylinder 6, on the center line of the thin-walled cylinder 6, it is fixed on one end of the rotary motion control system 9, and the other end of the rotary motion control system 9 is installed on the end of the line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com