Hierarchical algorithm of selective laser sintering

A laser sintering and layering algorithm technology, which is applied in computing, special data processing applications, instruments, etc., can solve the problems of slicing accuracy and error compensation, so as to improve accuracy, reduce memory usage, and improve layered processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

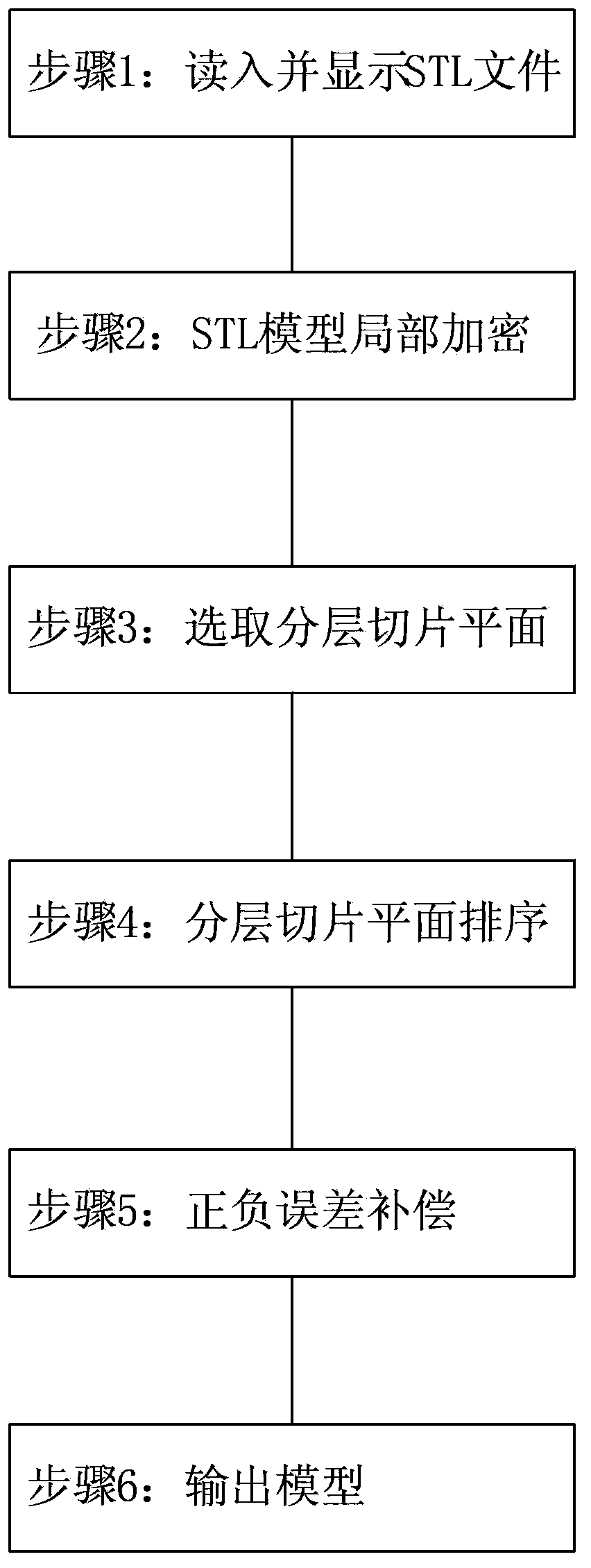

[0045] Such as figure 1 As shown, a layered algorithm of selective laser sintering of the present invention is used to establish an accurate product model, comprising the following steps:

[0046] Step 1: Read in and display the STL file. Since the STL file has two storage formats, ASCII and binary, the format of the file should be detected first, and the triangle surface information of the model should be calculated, and then the triangle surface information is read and saved. After the data is read, the related Directx11 is called function to display. Wherein, the information of the triangular face includes: the normal vector of the triangular face, three vertices and three edges.

[0047] Step 2: Partial encryption of the STL model. Firstly, the concave-convex feature of the model is judged according to the angle criterion and the gradient criterion, and then the feature is verified according to the positive or negative of the product C of the normal phase vector of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com