Super junction Schottky semiconductor device and preparation method thereof

A semiconductor and Schottky potential technology, which is applied in the field of super junction Schottky semiconductor devices, can solve the problems of high on-resistance, affecting the reverse breakdown characteristics of devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

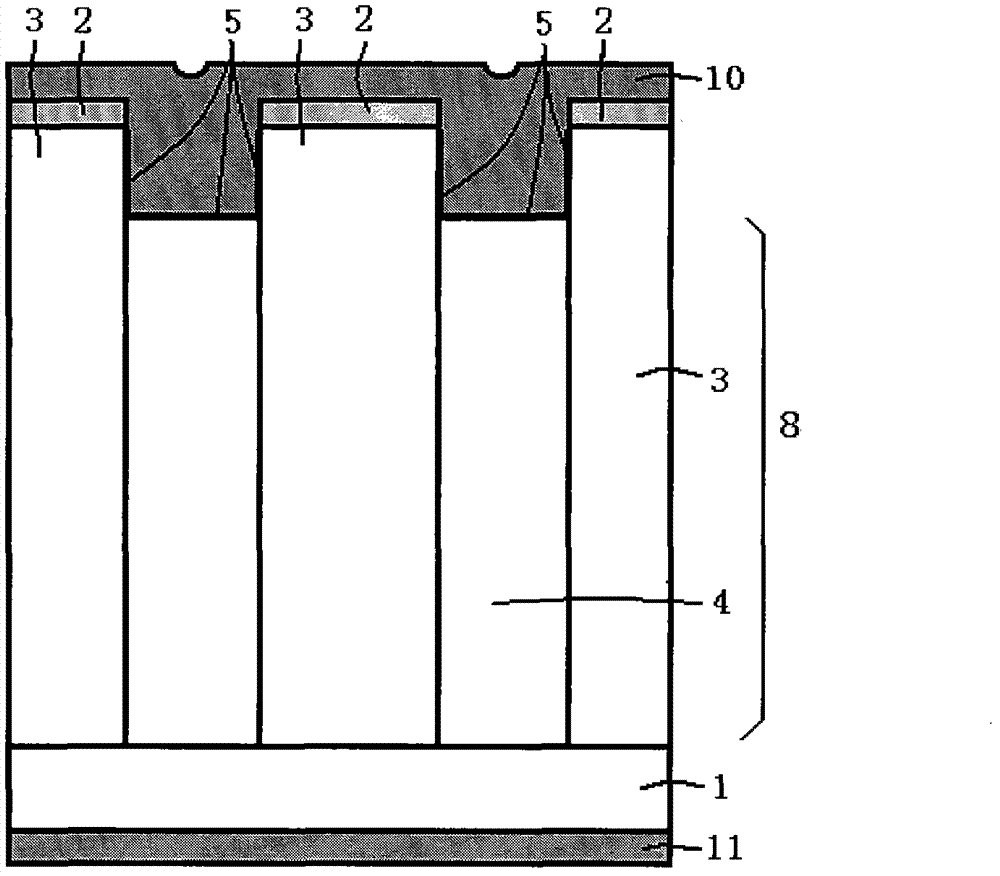

[0023] figure 1 It is a sectional view of a super junction Schottky semiconductor device of the present invention, combined below figure 1 The semiconductor device of the present invention will be described in detail.

[0024] A super-junction Schottky semiconductor device, comprising: a substrate layer 1, which is an N conductivity type semiconductor silicon material, and the doping concentration of phosphorus atoms is 1E19 / CM 3 , on the lower surface of the substrate layer 1, the electrodes are drawn out through the lower surface metal layer 11; the first conductive semiconductor material 3, located on the substrate layer 1, is a semiconductor silicon material of N conductivity type, and the doping concentration of phosphorus atoms is 1E16 / CM 3 ; The second conductive semiconductor material 4, located on the substrate layer 1, is a semiconductor silicon material of P conductivity type, and the doping concentration of boron atoms is 1E16 / CM 3 ; Schottky barrier junction 5, ...

Embodiment 2

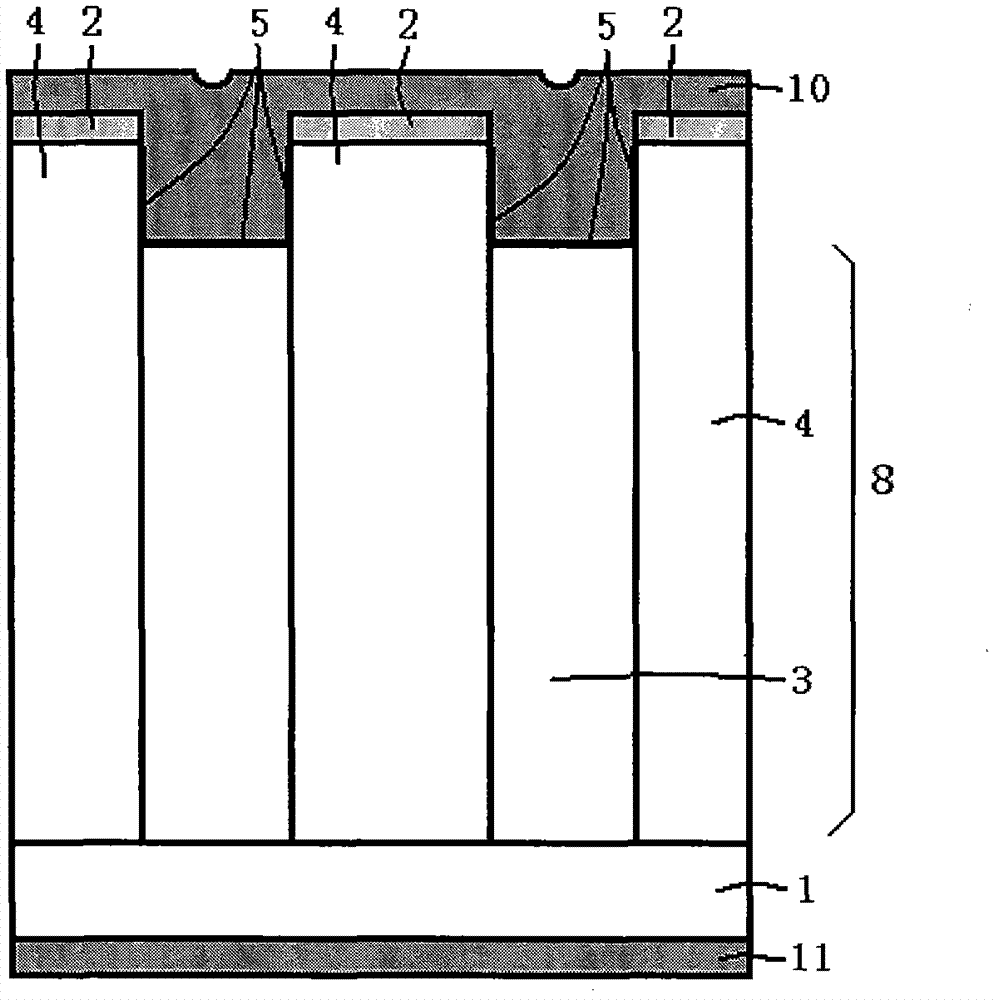

[0033] figure 2 It is a sectional view of a super junction Schottky semiconductor device of the present invention, combined below figure 2 The semiconductor device of the present invention will be described in detail.

[0034] A super junction Schottky semiconductor device, comprising: a substrate layer 1, which is a semiconductor silicon material of P conductivity type, and the doping concentration of phosphorus atoms is 1E19 / CM 3 , on the lower surface of the substrate layer 1, the electrodes are drawn out through the lower surface metal layer 11; the first conductive semiconductor material 3, located on the substrate layer 1, is a semiconductor silicon material of N conductivity type, and the doping concentration of phosphorus atoms is 1E16 / CM 3 ; The second conductive semiconductor material 4, located on the substrate layer 1, is a semiconductor silicon material of P conductivity type, and the doping concentration of boron atoms is 1E16 / CM 3 ; Schottky barrier junction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com