LED (Light-Emitting Diode) chip with high luminous efficiency and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, applied to electrical components, circuits, semiconductor devices, etc., to achieve the effects of reducing total reflection, improving light extraction efficiency, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

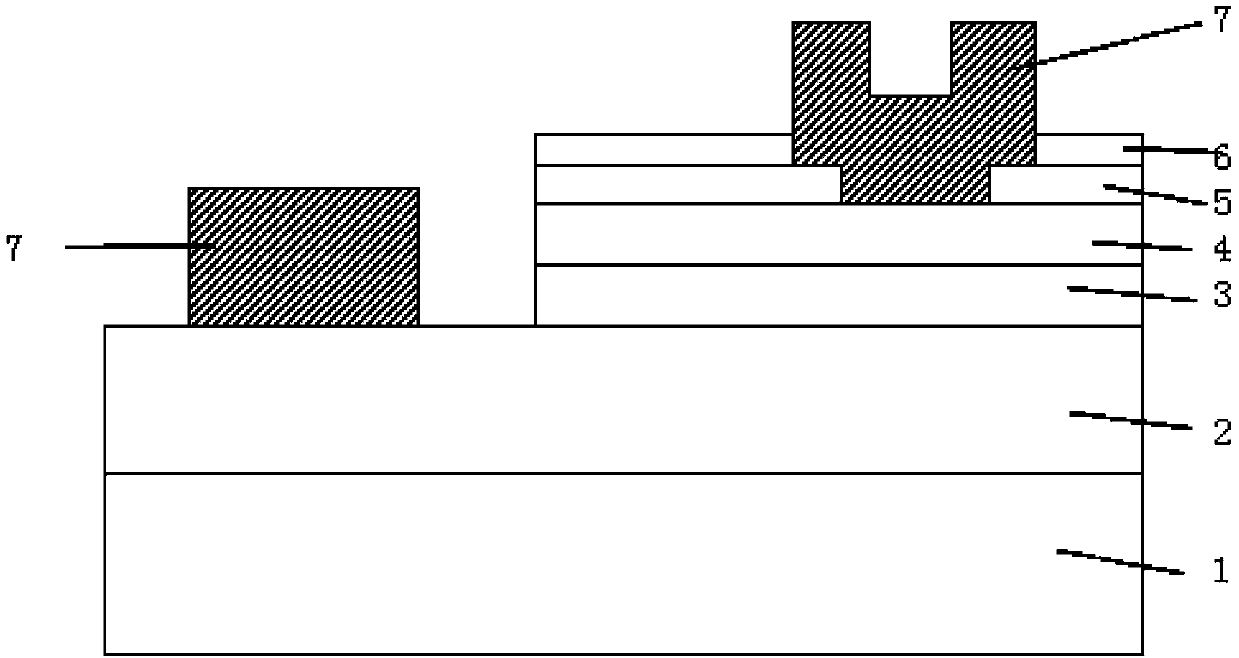

[0019] 1. On the sapphire substrate 1, grow the N-type GaN layer 2, the active layer 3 and the P-type GaN layer 4 in sequence, and remove part of the P-type GaN layer 4 and the active layer 3 by etching to expose a part of the N-type GaN layer 2.

[0020] 2. Evaporating a current spreading layer 5 on the P-type GaN layer 4 by means of electron beam evaporation. In this embodiment, the current spreading layer 5 is an ITO thin film layer. SnO in ITO evaporation source 2 with In 2 o 3 The mass percentage is 10:90, and the vacuum degree is 1.8×10 -5 Torr, the chamber temperature was maintained at 250 °C. first step, O 2 The flow rate is set to 15 sccm, the evaporation rate is 0.1 nm / s, the thickness is set to 57.4 nm, and the ITO film layer with a refractive index of about 2 is set. In the second step, O 2 The flow rate is set to 3 sccm, the evaporation rate is set to 0.15 nm / s, and the thickness is set to 66.5 nm to form an ITO thin film layer with a refractive index of ab...

Embodiment 2

[0024] 1. On the sapphire substrate 1, grow the N-type GaN layer 2, the active layer 3 and the P-type GaN layer 4 in sequence, and remove part of the P-type GaN layer 4 and the active layer 3 by etching to expose a part of the N-type GaN layer 2.

[0025] 2. Evaporating a current spreading layer 5 on the P-type GaN layer 4 by means of electron beam evaporation. In this embodiment, the current spreading layer 5 is an ITO thin film layer. SnO in ITO evaporation source 2 with In 2 o 3 The mass percentage is 5:95, and the vacuum degree is 1.8×10 -5 Torr, the chamber temperature was maintained at 250 °C. first step, O 2 The flow rate is set at 15 sccm, the evaporation rate is 0.2nm / s, the thickness is set at 56nm, and the ITO film layer with a refractive index of about 2.05. In the second step, O 2 The flow rate is set to 3 sccm, the evaporation rate is set to 0.25nm / s, and the thickness is set to 65.7nm to form an ITO film layer with a refractive index of about 1.72.

[00...

Embodiment 3

[0029] 1. On the sapphire substrate 1, grow the N-type GaN layer 2, the active layer 3 and the P-type GaN layer 4 in sequence, and remove part of the P-type GaN layer 4 and the active layer 3 by etching to expose a part of the N-type GaN layer 2.

[0030] 2. Evaporating a current spreading layer 5 on the P-type GaN layer 4 by means of electron beam evaporation. In this embodiment, the current spreading layer 5 is an ITO thin film layer. SnO in ITO evaporation source 2 with In 2 o 3 The mass percentage is 10:90, and the vacuum degree is 1.8×10 -5 Torr, the chamber temperature was maintained at 250 °C. first step, O 2 The flow rate is set to 12sccm, the evaporation rate is 0.1nm / s, the thickness is set to 58.9nm, and the ITO film layer with a refractive index of about 1.95. The second step 2The flow rate is set to 4sccm, the evaporation rate is set to 0.25nm / s, and the thickness is set to 65.3nm to form an ITO film layer with a refractive index of about 1.73.

[0031] 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com