Electric deionization device for producing deionized water

A technology of electrodeionization and deionized water, applied in electrodialysis, separation methods, semi-permeable membrane separation, etc., can solve problems such as ineffective functioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] One example of an embodiment of the electrodeionization apparatus for producing deionized water according to the present invention will be described with reference to the accompanying drawings.

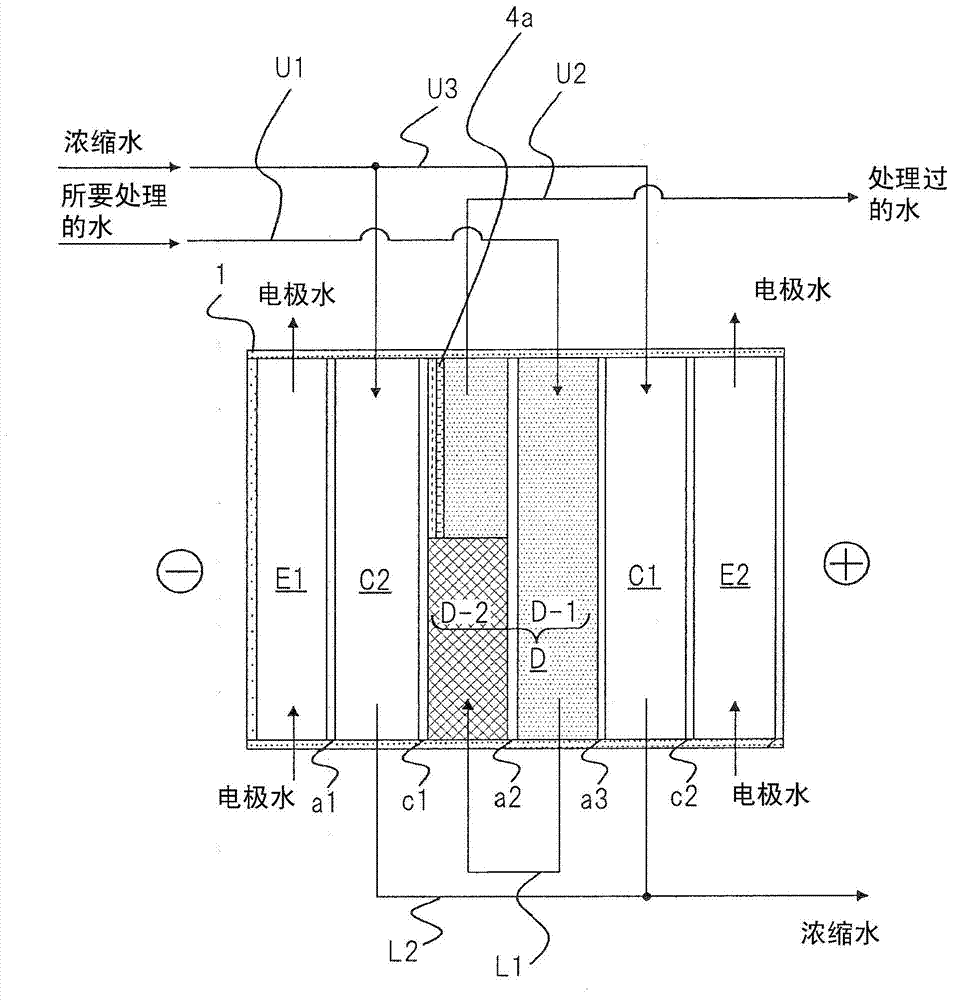

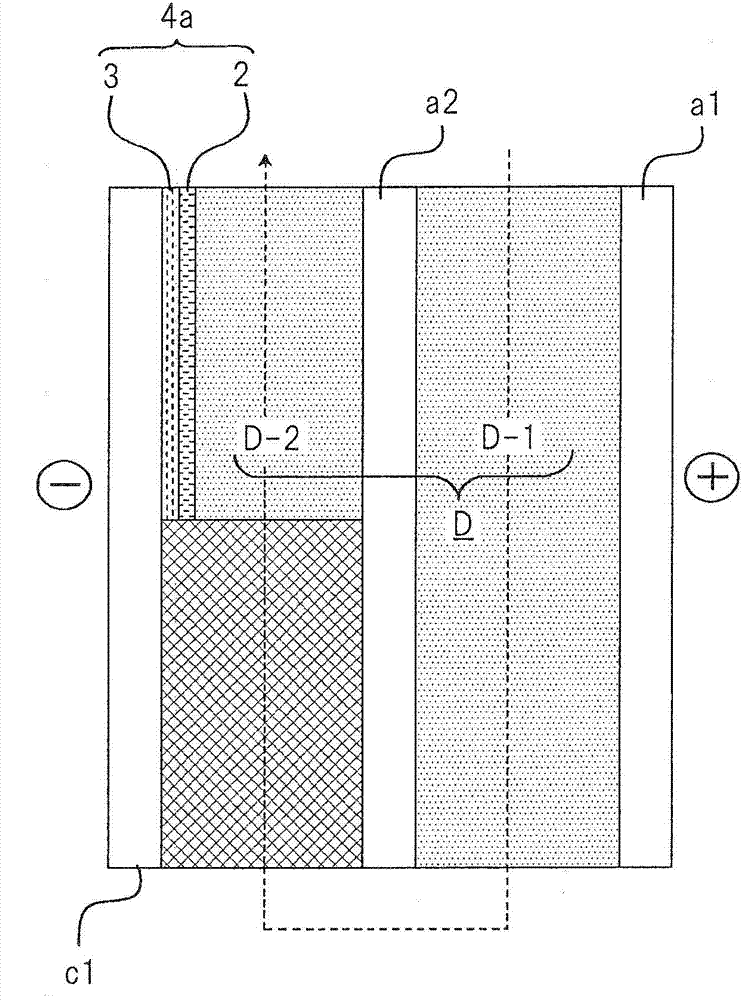

[0036] figure 1 is a diagram schematically showing the configuration of the deionized water production apparatus according to the present embodiment. exist figure 1 In the deionized water preparation device shown in , the deionization treatment unit is arranged between the cathode chamber E1 provided with the cathode and the anode chamber E2 provided with the anode. The deionization processing unit is composed of a deionization chamber D and a pair of concentrating chambers C1 and C2 disposed adjacent to the deionization chamber D on opposite sides thereof. In the following description, among the pair of concentrating chambers C1 and C2, the concentrating chamber C1 adjacent to the anode chamber E2 is referred to as "the first concentrating chamber C1", and the concentratin...

Embodiment approach 2

[0088] Another example of an embodiment of the electrodeionization apparatus for producing deionized water according to the present invention will be described with reference to the accompanying drawings. The deionized water production apparatus according to the present embodiment has the same configuration as the apparatus according to Embodiment 1 except that a plurality of deionization treatment units are disposed between the cathode chamber and the anode chamber. Therefore, only configurations different from the deionized water production apparatus according to Embodiment 1 will be described below. A description of the same configuration will not be made.

[0089] Figure 4 is a diagram schematically showing the configuration of the deionized water production apparatus according to the present embodiment. exist Figure 4 In the deionized water preparation device shown in , two deionized treatment units are arranged between the cathode chamber E1 and the anode chamber E2...

Embodiment approach 3

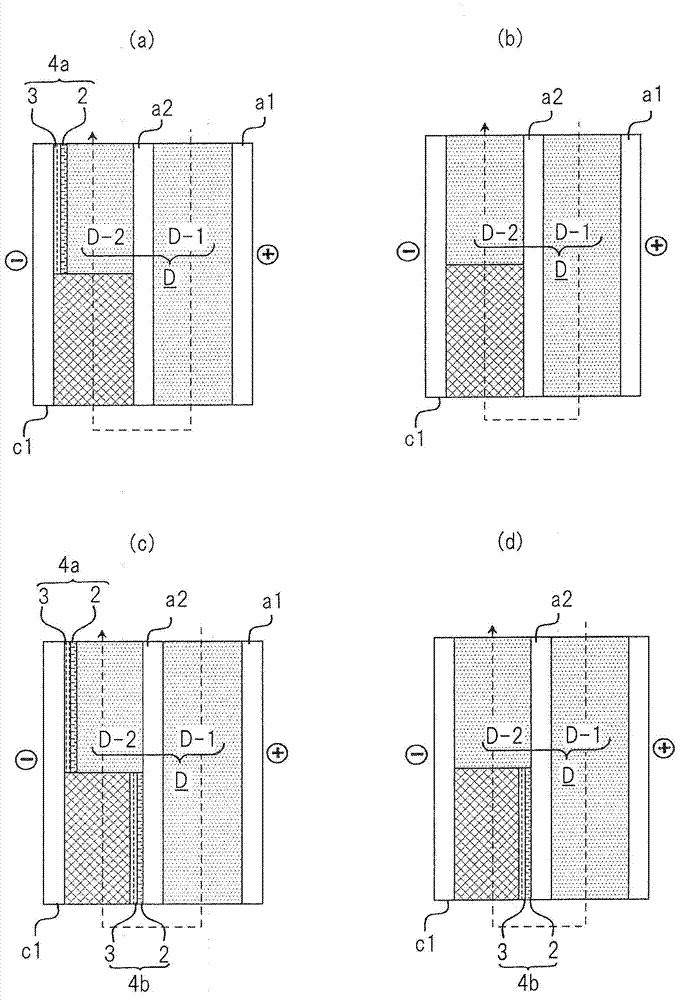

[0107] will refer to Figure 5 Yet another example of an embodiment of the deionized water producing apparatus according to the present invention is described. The deionized water production apparatus according to this embodiment has the same basic configuration as that according to Embodiment 2. Therefore, only the differences between the deionized water production apparatus of the present embodiment and the deionized water production apparatus of Embodiment 2 will be described below. Descriptions for the same points will not be repeated.

[0108] Such as Figure 5 As shown in , in the deionized water producing apparatus according to the present embodiment, the sub-deionization chamber S1 is disposed between the cathode chamber E1 and the second concentrating chamber C2. The sub-deionization chamber S1 is adjacent to the cathode chamber E1 with the sixth anion exchange membrane a6 interposed therebetween. The sub-deionization chamber S1 is adjacent to the second concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com