Manufacturing method of roasted fish fillets

A production method and a technology for grilling fish fillets, which are applied in the field of food processing, can solve the problems of backward development technology of mullet products, influence the development of mullet breeding industry, etc., and achieve the effects of effective development and utilization, unique flavor and easy portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention takes mullet as a raw material, and the processing steps of the present invention are as follows.

[0025] Raw material handling.

[0026] Select mullet with good freshness and complete shape, and after thawing, remove the scales, head, tail, and internal organs, remove surface blood stains, and clean the inner wall of the fish.

[0027] slice.

[0028] Enter the knife from 2cm from the tail of the fish, cut the fish into two pieces along the spinal cord, remove the spinal cord and fish bones, and then slice into slices, which should be as uniform in thickness as possible and suitable in size.

[0029] Go fishy.

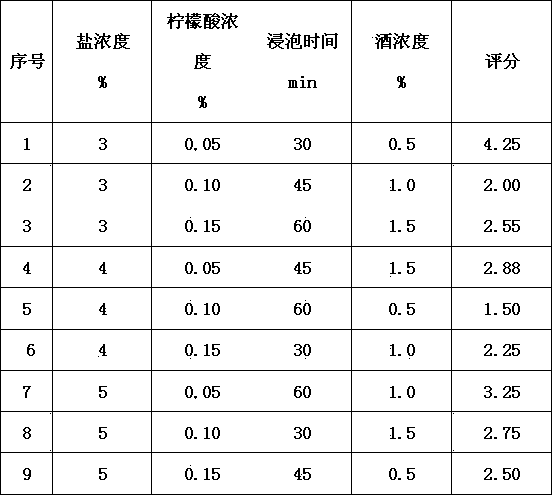

[0030] Use 3-5% sodium chloride, 0.05-0.15% citric acid, and 0.50-1.50% rice wine to make a deodorizing liquid, and soak the fish fillets for 30-60 minutes at a temperature of 20°C.

[0031] seasoning.

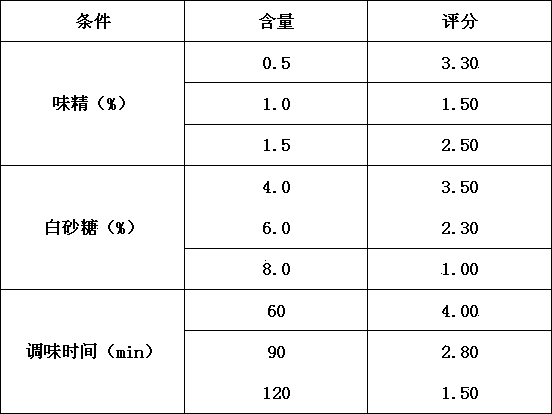

[0032] Use 4-8% white granulated sugar, 0.5-1.5% monosodium glutamate, 2-6% lactose, 0.1-0.3% transglutaminase (TG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com