Processing equipment and method for cutting fluid waste water

A waste water treatment, cutting fluid technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve environmental and human pollution, damage and other problems, achieve efficiency enhancement, guarantee Purification efficiency and the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

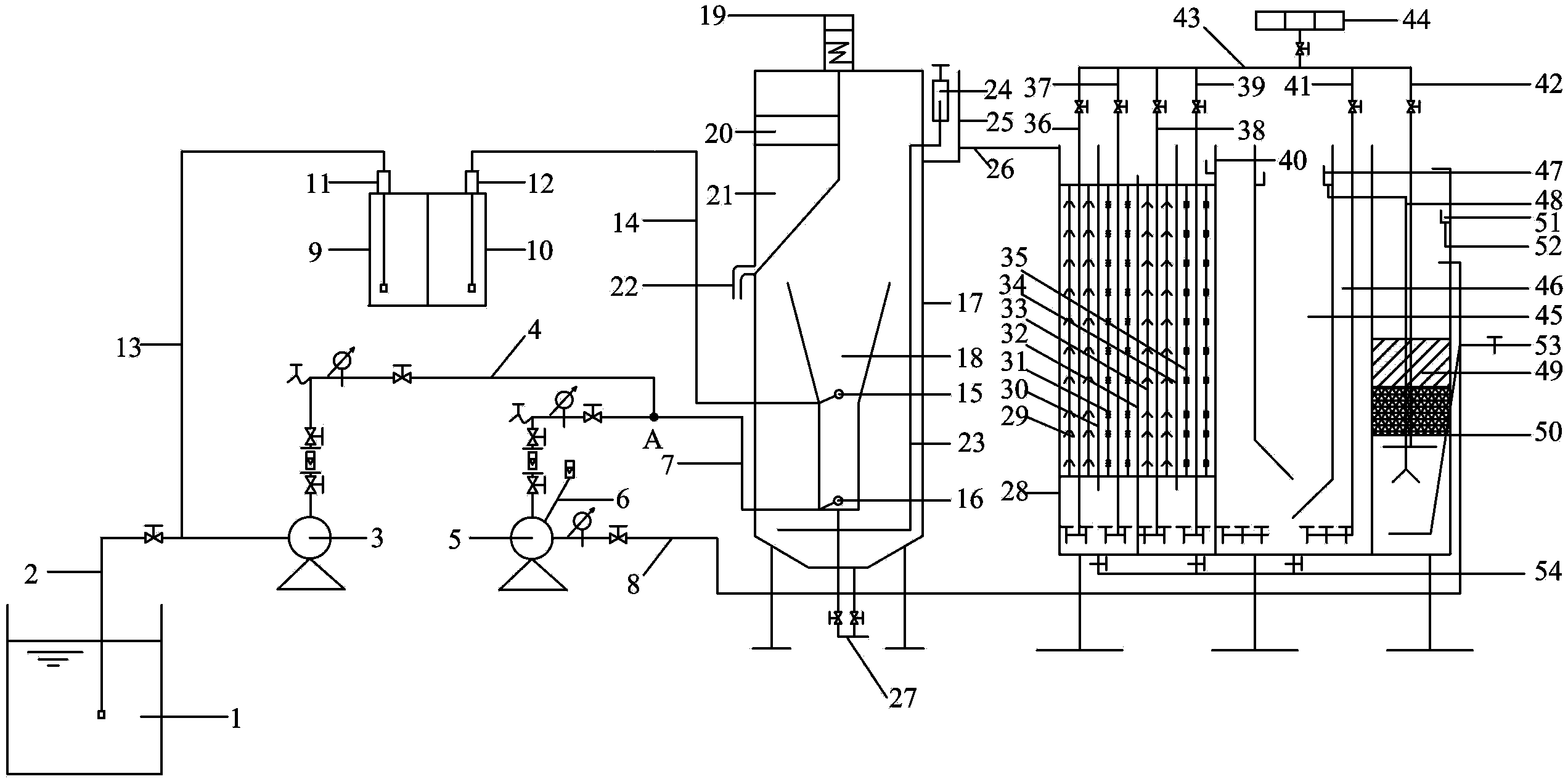

[0033] Such as figure 1As shown, a cutting fluid wastewater treatment equipment includes a sewage pump 3, a multiphase medium pump 5, a dosing system, a coagulation air flotation separation device 17 and an integrated purification device 28;

[0034] The sewage pool 1 is connected to one end of the sewage pump 3 through the water inlet pipe I2, and the other end of the sewage pump 3 is connected to the water outlet pipe I4; one end of the multiphase medium pump 5 is connected to the air inlet pipe 6 and the water inlet pipe II8, the other end of the multiphase medium pump 5 is connected to the water outlet pipe II7, and the water outlet pipe II7 and the water outlet pipe I4 are connected to the coagulation air flotation separation device 17 after being connected at point A in the figure. The liquid inlet 16 at the bottom of the reaction zone 18 is connected; the water inlet pipe II8 is connected with the middle part of the contact sedimentation filtration adsorption separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com