Clean jelly glue producing method

A technology for cleaning jelly glue and manufacturing methods, which is applied in chemical instruments and methods, pharmaceutical formulas, cosmetic preparations, etc., and can solve the problems of difficult dissolution, inconvenient use, and non-elasticity of solid detergents, and achieve easy-to-use volume, Easy to hold, not sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

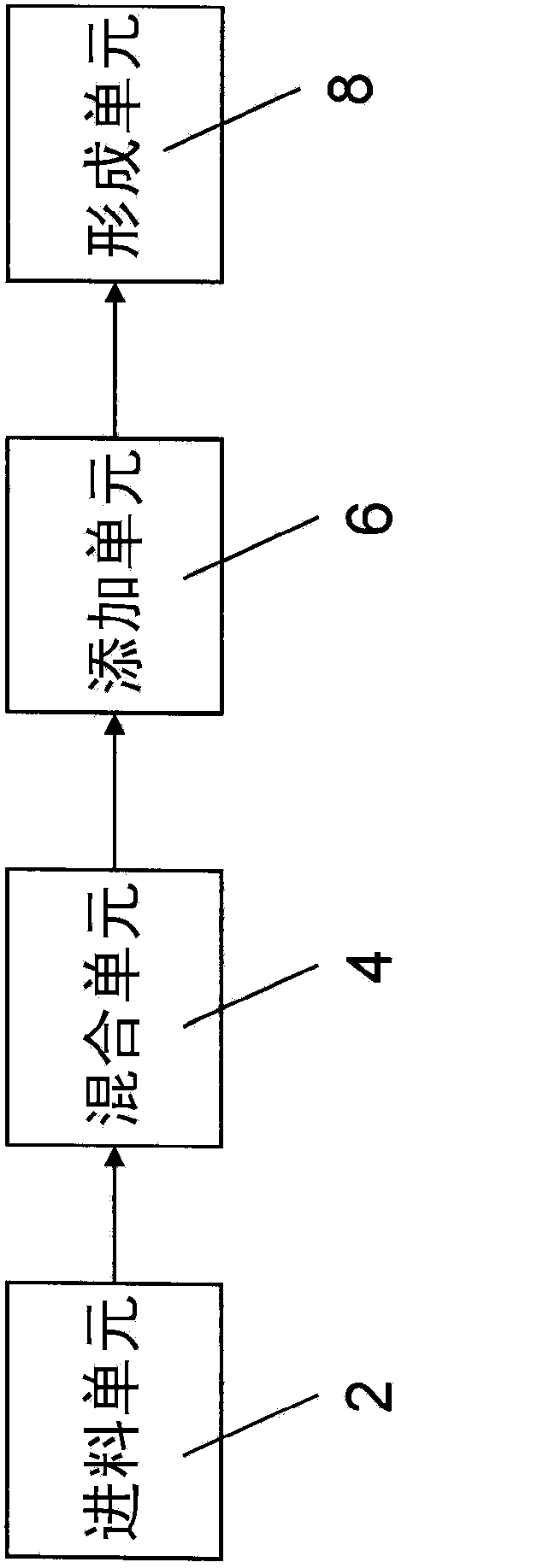

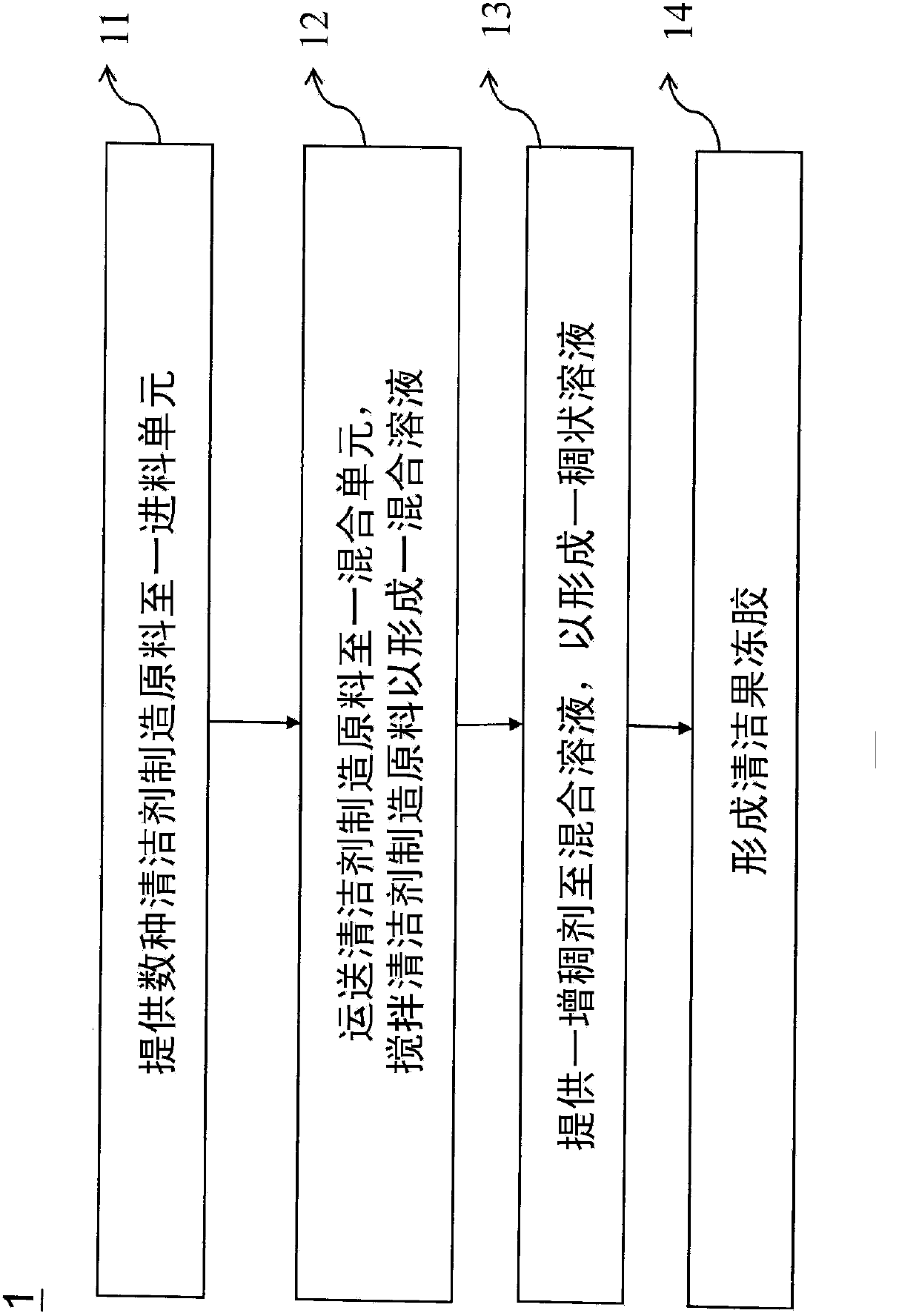

[0040] The manufacturing method of cleaning jelly gel provided by the present invention, this manufacturing method comprises: provide cleaning agent manufacturing raw material; Transport cleaning agent manufacturing raw material to a mixing unit; Stir cleaning agent manufacturing raw material to form a mixed solution; Provide a thickener to mix Solution to form a thick solution; transport the thick solution to a forming unit; heat the forming unit to dry the surface of the thick solution to form a clean jelly gel with a specific shape, the outer layer is elastic and has hydrophilic functions base.

[0041] Since the present invention discloses a method for producing clean jelly gel, the equipment, devices, and raw materials used therein are achieved by using existing technologies, so in the following description, a complete description will not be made. In addition, the drawings in the following texts are not completely drawn according to the actual relevant dimensions, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com