Dynamic compactor capable of quickly releasing rope

A dynamic tamping machine, fast technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems that the speed of steel wire rope can not reach the speed of free fall, increase workload, splash of gravel, etc., to achieve great practicality and promotion value, reduce labor intensity, and facilitate the effect of quick and easy slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

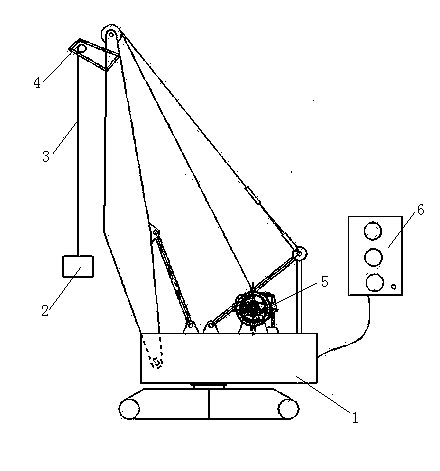

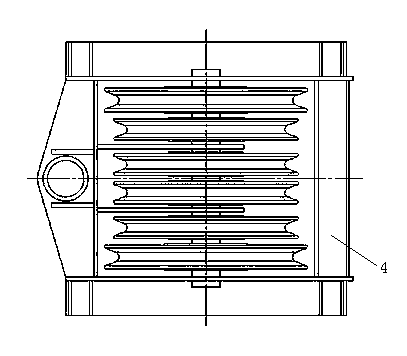

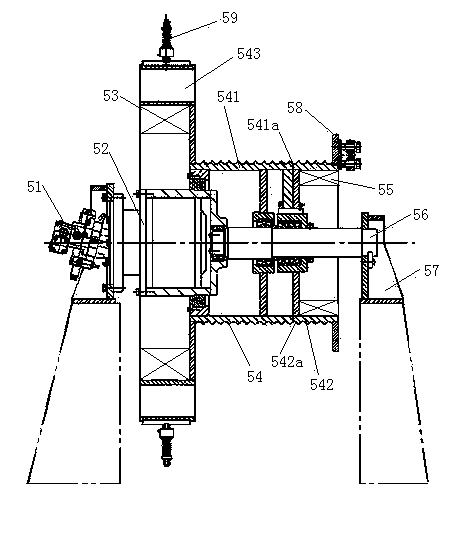

[0020] Refer to attached figure 1 , attached figure 2 , attached image 3 , a fast rope-releasing dynamic tamping machine of the present invention, which is composed of a frame 1, a rammer 2, a steel wire rope 3, a pulley mechanism 4, a hoist 5, and a control component 6. The frame 1 can be a crawler-type mobile vehicle Body, tower frame, "L" type frame wherein a kind of structural form, the frame 1 of present embodiment is the structural form of crawler type mobile car body, rammer 2 is arranged on the pulley mechanism 4 by steel wire rope 3; Wire rope 3 links to each other with winch 5 through pulley mechanism 4, and described pulley mechanism 4 is the rope-releasing mechanism of a multi-group fixed pulley structure; Described control part 6 is used for controlling the work of complete machine and winch 5; Described winch 5 is a fast unwinding rope winding mechanism with a main reel 541 and an auxiliary reel 542 that can rotate simultaneously and rotate separately. And t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com