Spherical integrated type gas filter

A gas filter, conjoined technology, applied in the field of gas filters, can solve the problems that the measurement accuracy cannot meet the development requirements, cannot be accurately measured, and the filtration is rough, and achieves convenient connection form conversion, easy production, and high filtration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings.

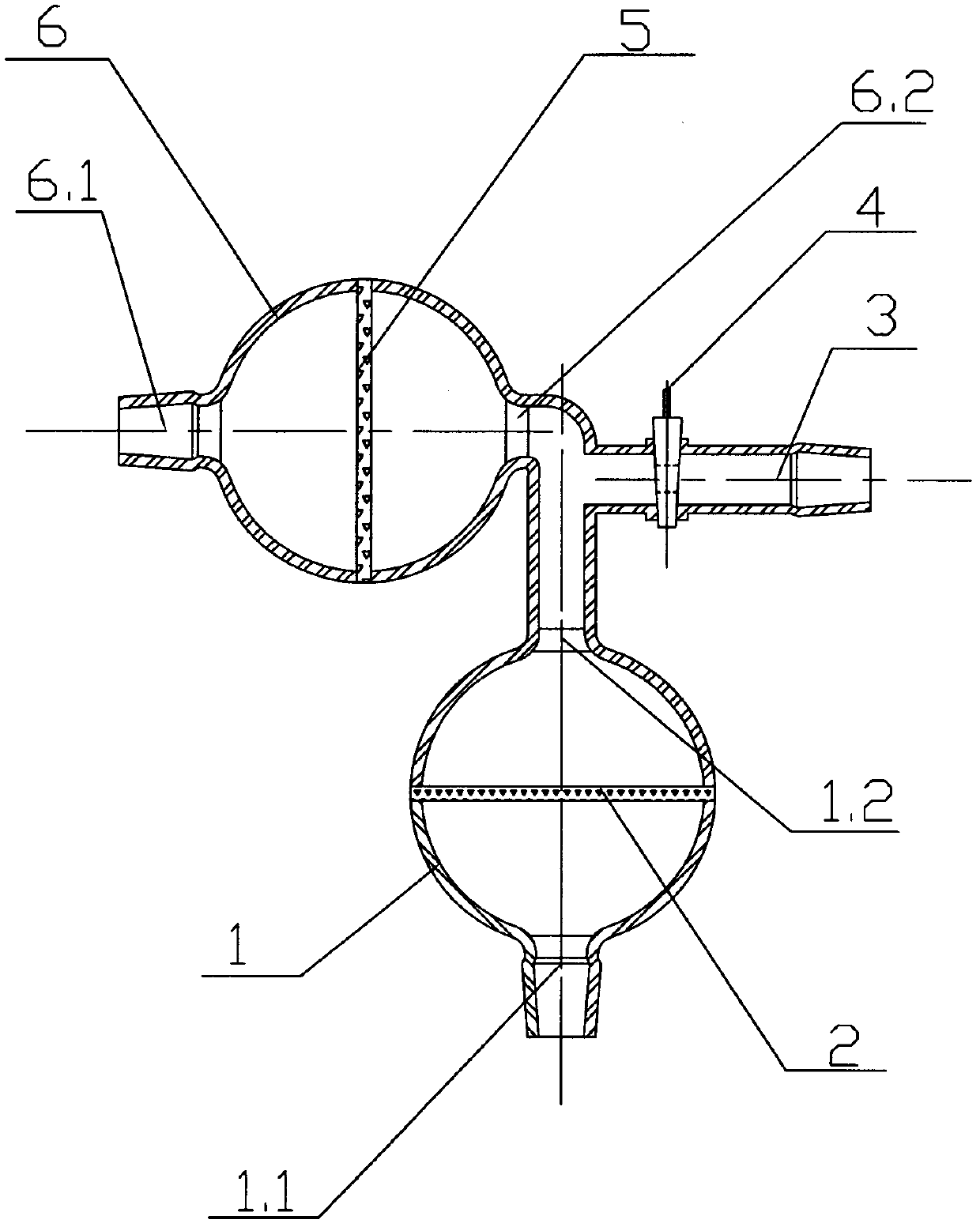

[0013] figure 1 The spherical conjoined gas filter shown includes a lower casing 1 , a front sand core 2 , a branch pipe 3 , a valve 4 , a rear sand core 5 and an upper casing 6 . Both the lower shell 1 and the upper shell 6 are spherical glass products, the flat front sand core 2 is located in the inner cavity of the lower shell 1 and is sintered into one with the inner wall, and the upper and lower ends of the lower shell 1 are respectively provided with communication Lumen connection 1.1 and channel 1.2. The rear sand core 5 is placed vertically in the inner cavity of the upper casing 6 and is sintered into one body with the inner wall. The left and right ends of the upper casing 6 are respectively provided with an interface 6.1 and a channel 6.2 communicating with the inner cavity. The branch pipe 3 is a round straight pipe, the middle section of which is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com