Conjoined concatenation type gas absorbing pipe

A gas absorption and series connection technology, which is applied in the field of gas absorption tubes for electrochemical analysis of petrochemical samples, can solve the problems of increasing pipeline connection joints and installation difficulty, long electrochemical analysis process, poor measurement efficiency, etc., and achieves improved measurement and analysis. Efficiency, easy production, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

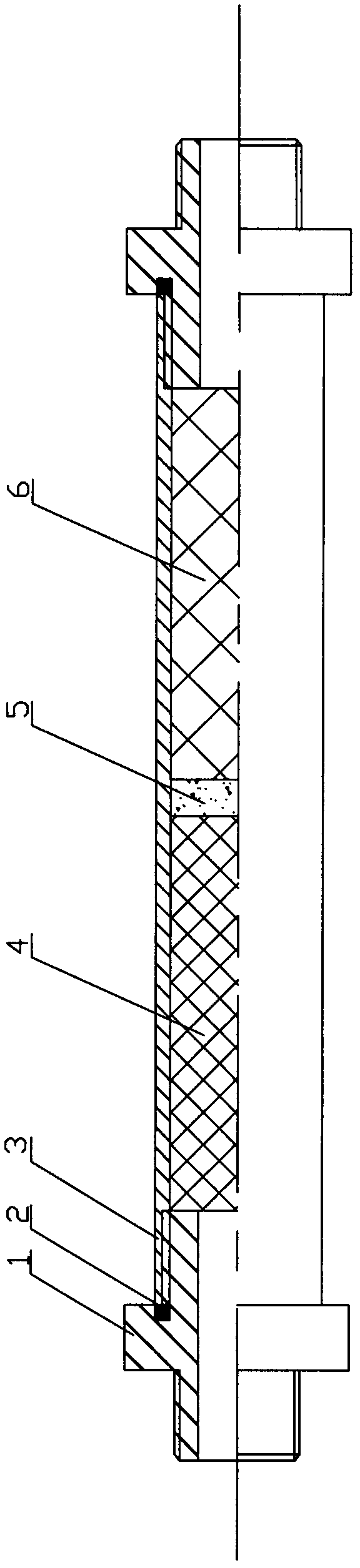

[0012] The present invention will be further described below according to the accompanying drawings.

[0013] figure 1 The conjoined serial gas absorption tube shown is composed of a cock 1, a sealing ring 2, a shell 3, an A medium 4, a filter plate 5 and a B medium 6. The cock 1 is a component with external threads at both ends, the axial through hole runs through the cock 1 , and the inner end surface of the cock 1 is provided with an annular groove to embed a sealing ring 2 . The tube shell 3 is a circular tube with equal diameters, and the internal threads at both ends cooperate with the large-diameter external thread end of the cock 1 . The filter sheet 5 is a disc honeycomb ceramic with 200-400 micropores / cm 2 . The improvement is that the filter plate 5 is plugged in the middle section of the shell 3 to form two cavities, and the A medium 4 and the B medium 6 are respectively plugged in the respective cavities and connected into one body by the cock 1 .

[0014] Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com