Transversely-arranged high-current electron beam cross section three-dimensional scanning measurement system

A measurement system and three-coordinate technology, applied in the direction of current density measurement, etc., can solve the problems of costing manpower, material resources, measuring the transmission characteristics of the entire electron beam, and being unusable, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

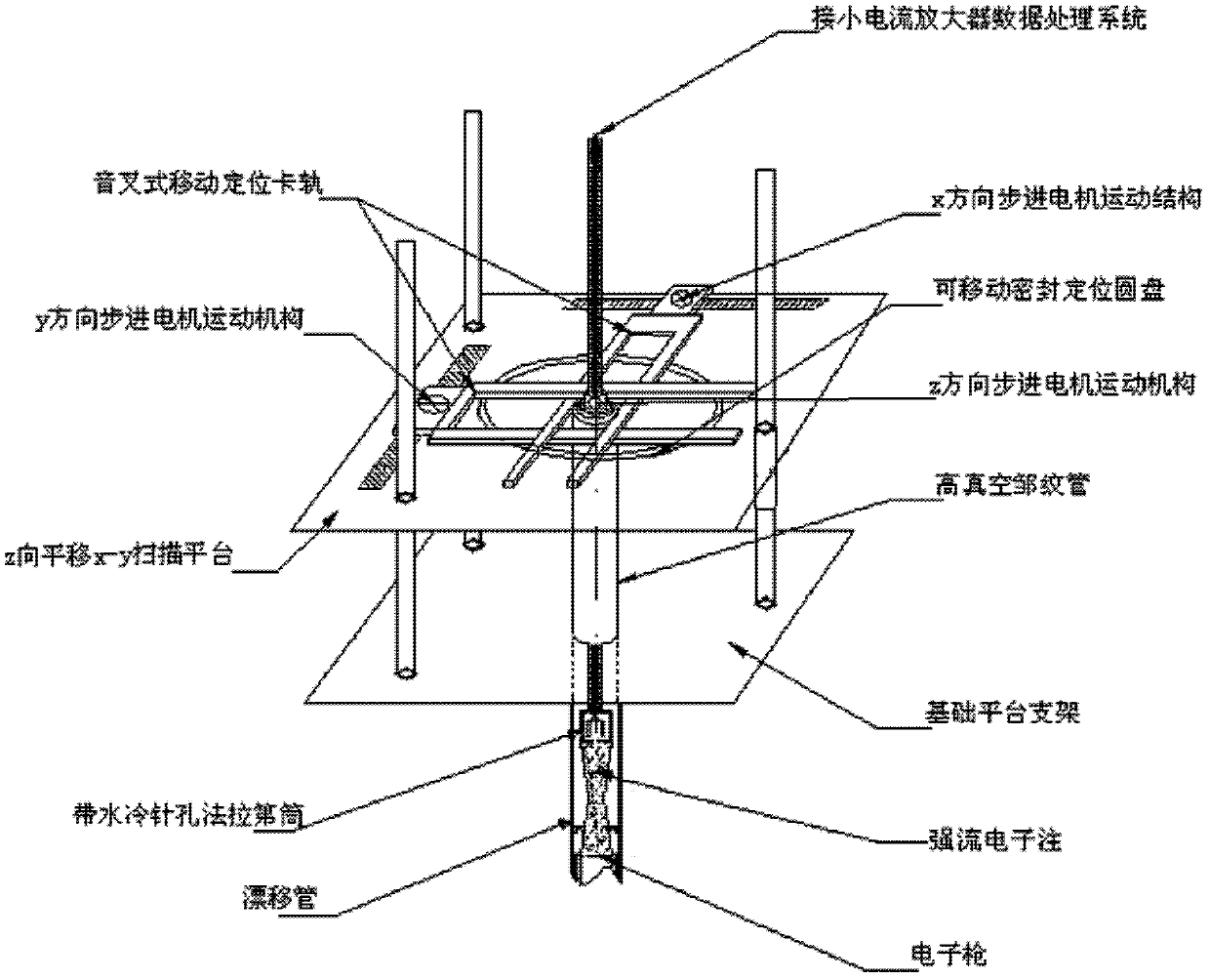

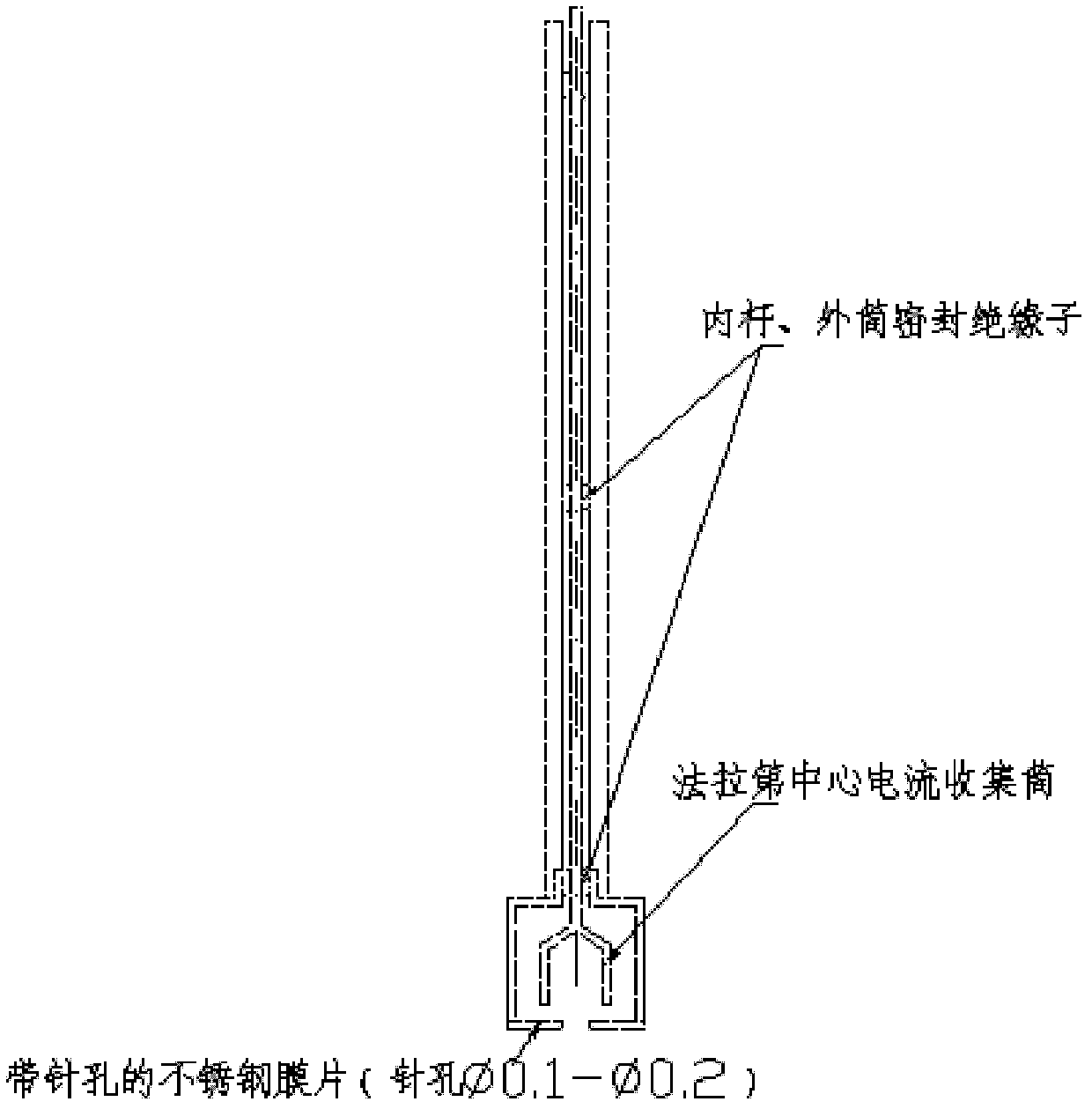

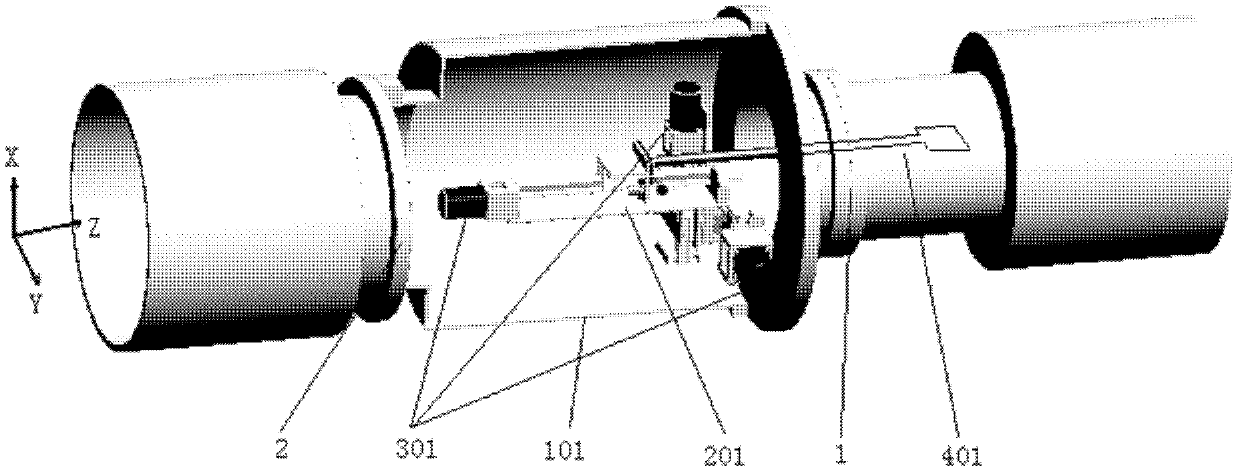

[0029] image 3 It is a structural schematic diagram of the three-coordinate scanning measurement system for the high-current electron beam section of the present invention, Figure 4 It is a schematic diagram of the X-Y cross-sectional structure of the three-coordinate precision platform of the present invention, Figure 5 It is a structural schematic diagram of the water-cooled Faraday cage of the present invention. Depend on image 3 , Figure 4 , Figure 5 It can be seen that the three-coordinate scanning measurement system of the high-current electron beam section of the present invention includes a measurement work area cavity 101, the cavity 101 includes an observation window, a low-voltage feed head 3, a front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com