Machine vision two-dimension detecting platform device

A machine vision and inspection platform technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as the inability to guarantee the inspection pass rate, the inability of the human eye to perform continuously and stably, the increase of labor costs and management costs in factories, etc. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

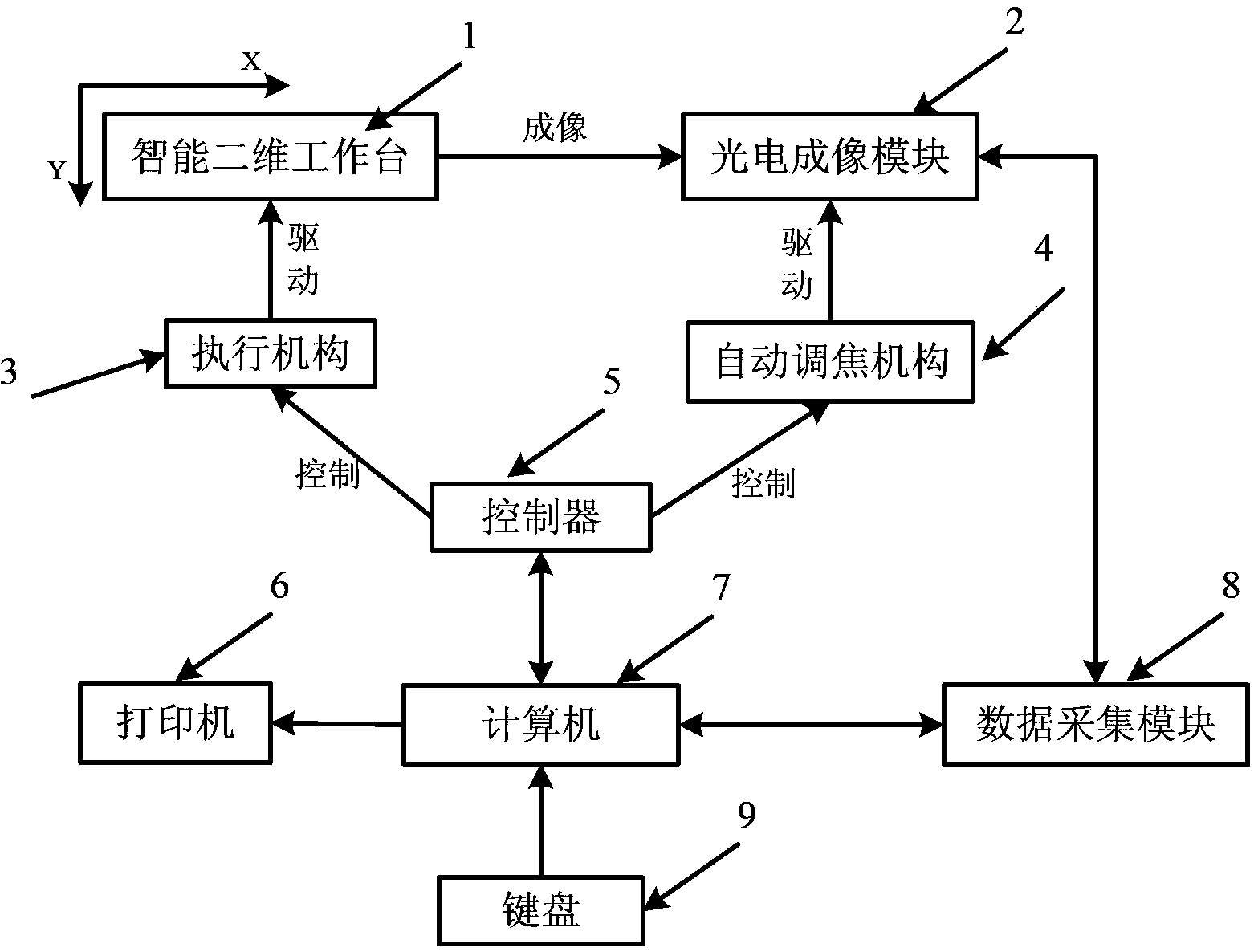

[0018] refer to figure 1 , a machine vision two-dimensional detection platform device, including an imaging system that can complete image acquisition, a support system that can support an object to be detected, and a control system that controls the above two systems. The imaging system includes a photoelectric imaging module 2 and data Acquisition module 8, the support system includes a two-dimensional workbench 1 and an actuator 3, the control system includes a controller 5 and a computer 7; the controller 5 and the computer 7 are bidirectionally connected, and the controller 5 receives the computer 7 control instructions, the computer 7 is bidirectionally connected to the data acquisition module 8; the controller 5 controls the actuator 3 and the photoelectric imaging module 2 respectively, and the actuator 3 and the two-dimensional 1 drive connection, the two-dimensional workbench 1 is connected to the photoelectric imaging module 2, and the photoelectric imaging module 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com