High-reconstitution-property dry Chinese yam and preparation method thereof

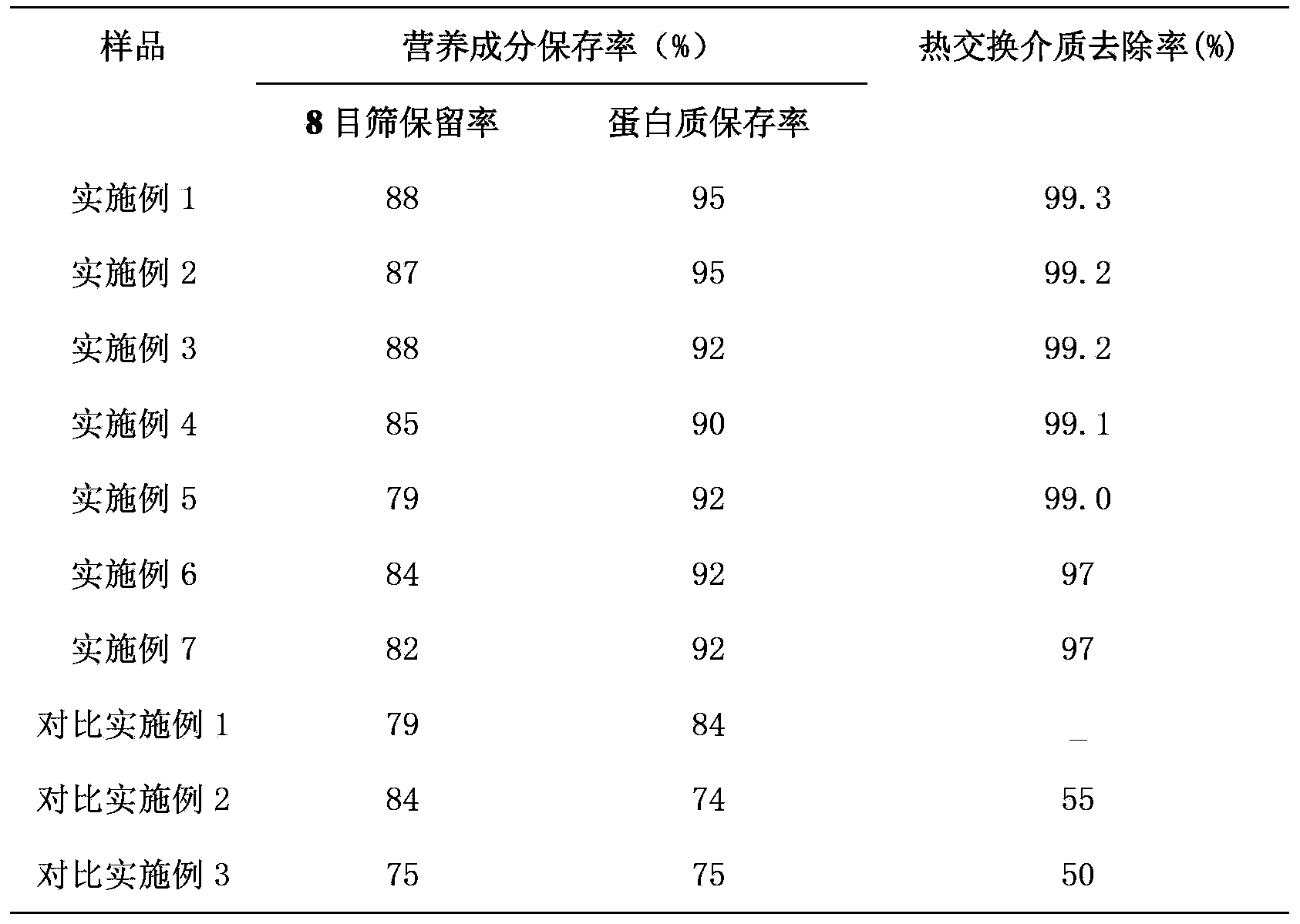

A rehydration and drying technology, which is applied in the field of food processing, can solve the problems of poor removal rate of nutrient preservation medium, and achieve the effect of crisp and tender taste, intact shape and high removal rate of medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

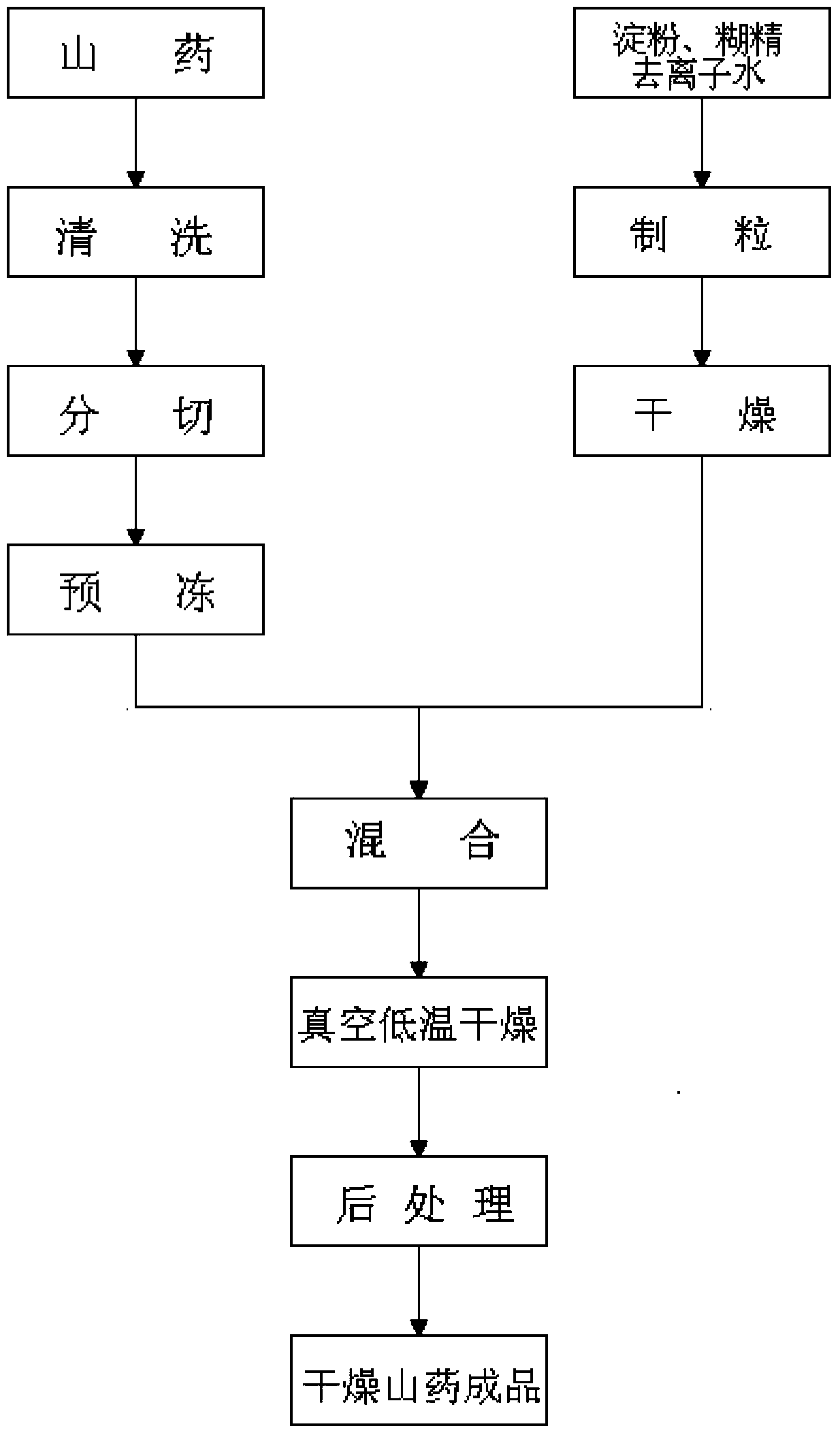

Method used

Image

Examples

Embodiment 1

[0024] Wash and peel the fresh yam, cut it into 15mm slices, put it in a freezer at minus 10°C for 8 hours, and mix it with starch, dextrin, and deionized water in parts by weight of 5:1:6, fully After mixing, granulate, dry until the water content is 10% to obtain heat exchange medium; mix the treated raw material and heat exchange medium in parts by weight of 5:10 to obtain a mixture; add it to a heating agitator, close the vacuum well or In the vacuum chamber, turn on the vacuum pump, turn on the refrigeration and turn on the stirring function at the same time. The stirring speed is controlled at 5R / min. After the vacuum degree drops to 100Pa, turn on the heating function and the heating temperature is controlled at 20°C. After 6 hours of treatment, take out the mixture with a moisture content of 8%. Sieve through a 20-mesh sieve, remove the heating medium, and obtain the target object—dried yam product.

Embodiment 2

[0026] Wash and peel the fresh yam, cut it into pieces of length 40mm×width 20mm×height 20mm, put it in a freezer at minus 80°C for 12 hours; use 5:2:8 starch, dextrin, Deionized water is used for batching, fully mixed, granulated, and dried until the moisture content is 6% to obtain a heat exchange medium; the treated raw material is mixed with the heat exchange medium at a weight ratio of 5:10 to obtain a mixture; add heat and stir In the container, close the vacuum well or vacuum chamber, turn on the vacuum pump, start the refrigeration and turn on the stirring function at the same time. The stirring speed is controlled at 5R / min. After the vacuum degree drops to 100Pa, the heating function is turned on. The heating temperature is controlled at 20°C. The mixed material with a ratio of 10% is sieved through a 20-mesh sieve, and the heating medium is removed to obtain the target object-dried yam finished product.

Embodiment 3

[0028] Wash and peel the fresh yam, cut it into pieces of length 40mm×width 30mm×height 30mm, put it in a freezer at minus 20°C for 13 hours; use starch, dextrin, Deionized water is used for batching, fully mixed, granulated, and dried until the water content is 6% to obtain a heat exchange medium; the treated raw material and heat exchange medium are mixed according to the weight ratio of 5:12 to obtain a mixture; add heating and stirring In the container, close the vacuum well or vacuum chamber, turn on the vacuum pump, start the refrigeration and turn on the stirring function at the same time. The stirring speed is controlled at 6R / min. After the vacuum degree drops to 100Pa, the heating function is turned on and the heating temperature is controlled at 30°C. The mixed material with a ratio of 10% is sieved through a 20-mesh sieve, and the heating medium is removed to obtain the target object-dried yam finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com