Manufacturing method of multislot eccentric workpiece and cold heading reducing die

A technology of cold heading and diameter reduction, which is applied in the manufacture of multi-groove eccentric workpieces, cold heading shrinking dies, and multi-groove eccentric bolt manufacturing. It can solve the problems of low production efficiency and high processing costs, reduce production costs, and optimize product processing. The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

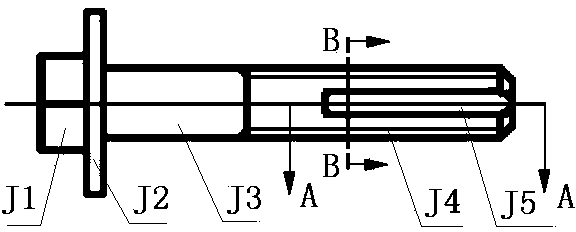

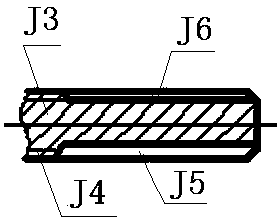

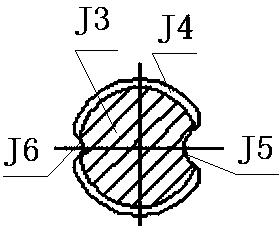

[0018] In an embodiment of the present invention, a two-groove eccentric workpiece manufacturing method is as follows figure 1 , figure 2 , image 3 Shown: the first step: cold heading, the bolt end J1, the bolt flange J2, the screw J3, the first groove J5 and the second groove J6 of the screw groove are sequentially processed at each station of the cold heading machine; the second step : thread rolling, the thread rolling machine processes the threads on the screw rod J3.

[0019] Such as Figure 4 As shown: the rod portion J3 is divided into a uniform deformation zone J7 and a uniform deformation zone J8, and a first groove J5 and a second groove J6 in a non-uniform deformation zone in the radial and circumferential direction. The first groove J5 and the second groove J6 in the non-uniform deformation area flow at different speeds relative to the uniform deformation area J7 and the uniform deformation area J8; Partial radial cold heading shrinkage deformation at the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com