Reflection film and preparation method thereof

A technology of film and reflective layer, applied in the field of reflective film and its preparation, can solve problems such as scratches on light guide plates, and achieve the effects of improving brightness, good optical performance, and brightness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

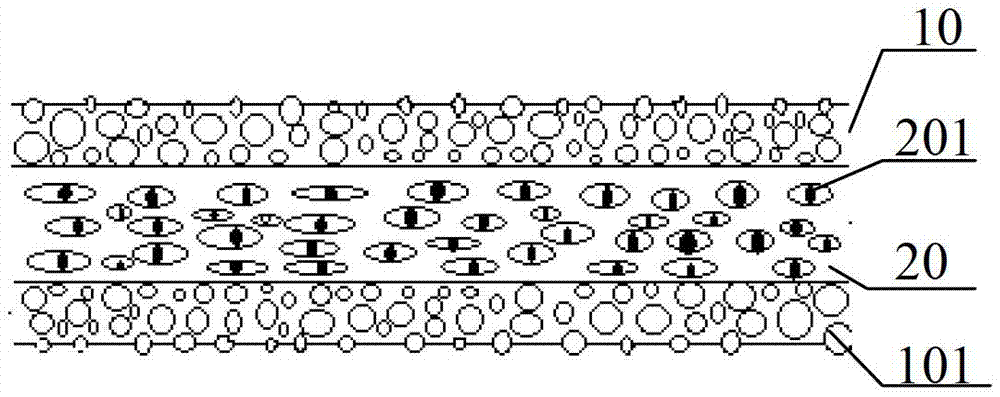

[0039] The preparation method of the reflective film provided by the present invention comprises the following steps (the following contents are all weight percentages):

[0040] (1) Preparation process of diffusion masterbatch

[0041] The production method is: mixing organic microbeads, dispersant, coupling agent, diluent and antioxidant, and granulating through a twin-screw extruder; the dosage of additives is shown in Table 1.

[0042] Table 1 additive dosage

[0043] Additives

coupling agent

Dispersant

Thinner

Dosage (%)

0.5-6

1-2

0.5-2

0.5-6

[0044] (2) Preparation of molten mixture

[0045] Auxiliary extruder: mix and feed polyester bright slices and 10-50% diffusion masterbatch slices through a weight loss scale, and extrude to obtain a molten mixture for the diffusion layer;

[0046] Main extruder: add 5-20% BaSO 4 The PP masterbatch (or other resin masterbatch containing inorganic particles) is ...

Embodiment 1

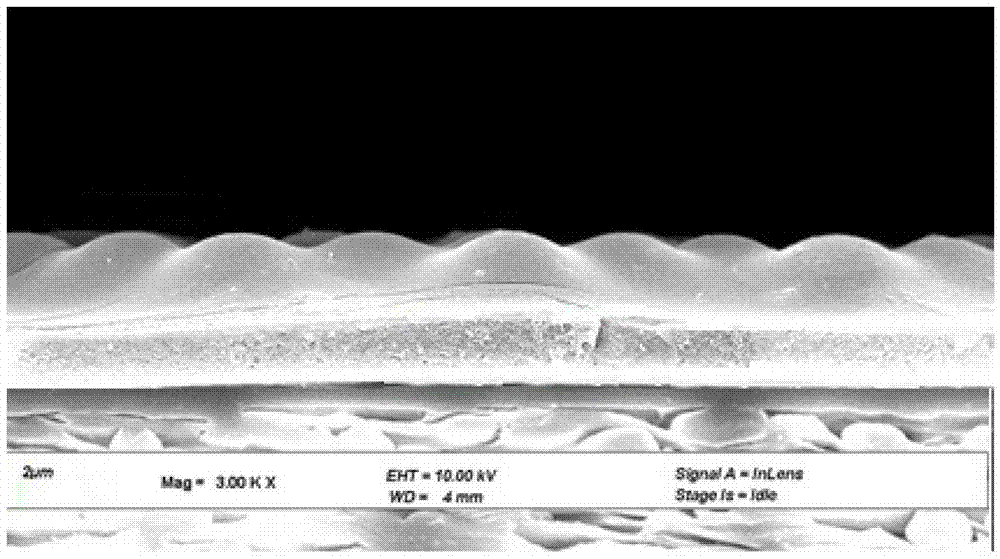

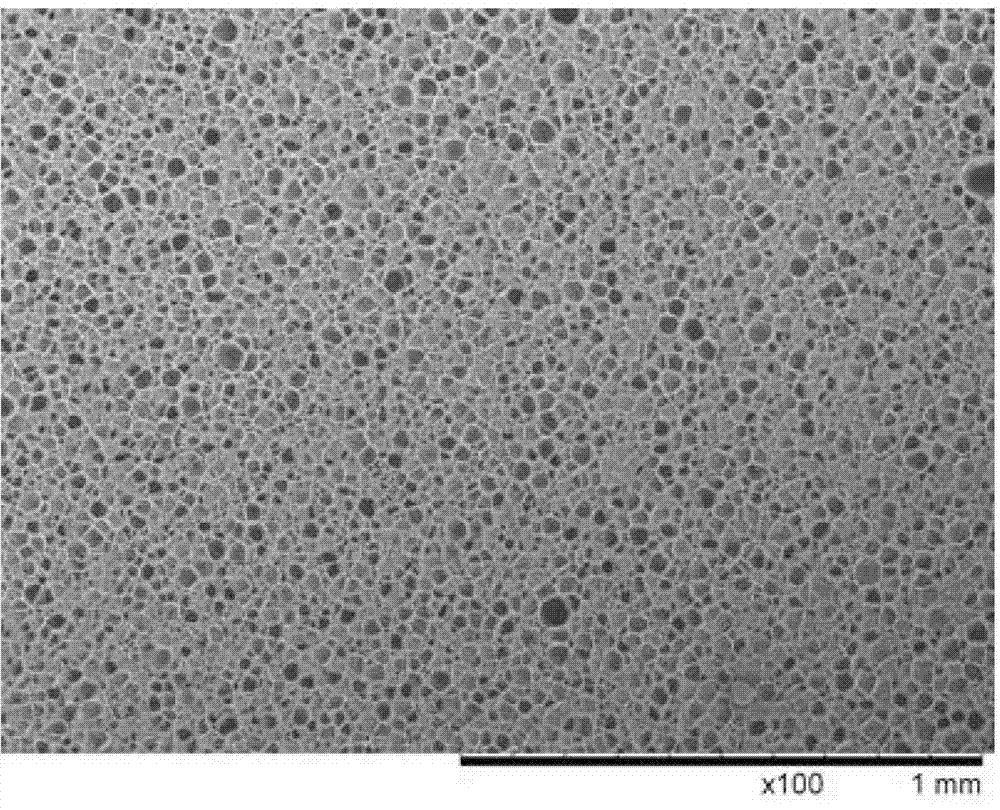

[0059] Prepare an optical reflection film according to the aforementioned method, wherein the particle diameters of the light-diffusing particles are 2 μm and 8 μm, respectively accounting for 50% of the total weight of the light-diffusing particles, and then mix and granulate the diffusion particles with polyester materials and additives to prepare diffusion masterbatches , the diffusion masterbatch includes 10% diffusion particles, 1.5% dispersant, 3% coupling agent, 2.5% diluent, 1% antioxidant, and 82% polyester material. The obtained diffusion masterbatch is mixed with 70% polyester base material in the addition amount of 30%, and melted and extruded through the auxiliary extruder; the BaSO-containing 4 The PP masterbatch is mixed with 80% polyester base material in an additive amount of 20%, and melted and extruded through the main extruder; roll, prepare the optical reflection film provided by the present invention, the performance of the obtained film is shown in Table...

Embodiment 2

[0061] Prepare the optical reflection film according to the aforementioned method, wherein the light-diffusing particles are organic silicon, and the particle diameters are 2 μm and 8 μm, respectively accounting for 50% of the total weight of the light-diffusing particles; the diffusion masterbatch includes 10% of the diffusion particles, 1% of the dispersed agent, 0.5% coupling agent, 0.5% thinner, 0.5% antioxidant, and 87.5% polyester material. The resulting diffusion masterbatch is mixed with 90% polyester base material in an additive amount of 10%, extruded through an auxiliary extruder to prepare a diffusion layer; 3 The TPU masterbatch is mixed with 90% of the polyester base material in an amount of 10%, extruded through the main extruder to prepare the reflective layer; Prepare the optical reflective film provided by the present invention, and the properties of the obtained film are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com