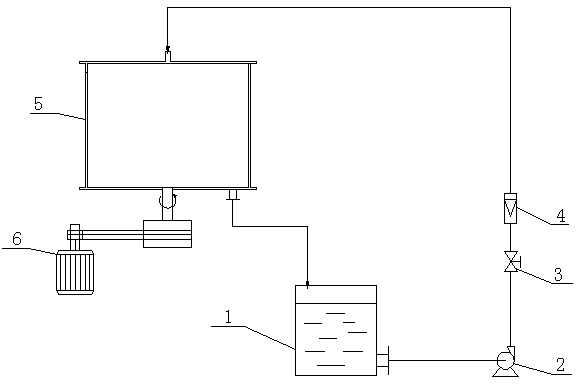

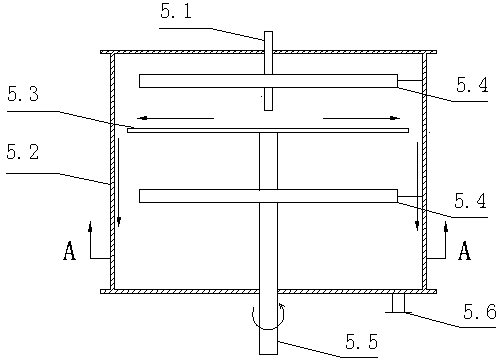

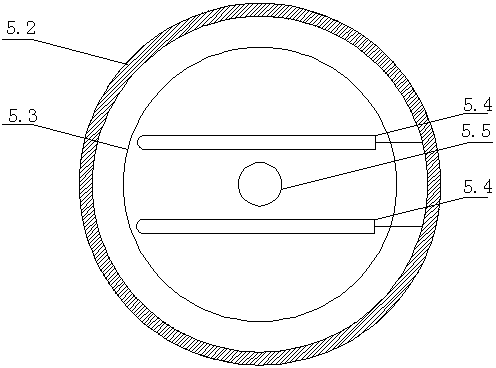

Device and method for photo-catalytically degrading phenol-containing wastewater

A phenolic wastewater and photocatalytic technology, applied in chemical instruments and methods, energy wastewater treatment, light water/sewage treatment, etc., can solve the problems of complex photocatalytic reactor structure, difficult industrial application, and difficult separation of catalysts. The effect of industrial design enlargement, simple structure and light loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the method for photocatalytic degradation containing phenolic wastewater

[0032] The above-mentioned device is used to treat phenol-containing wastewater. The treatment object is 500mg / L simulated phenol wastewater. The volume of wastewater is 1L. The materials of the turntable and the shell are stainless steel. The nano-titanium dioxide is loaded on the surface of the turntable and the inner wall of the shell by a binder method. The specific steps are:

[0033] (1) Put nano-titanium dioxide into an organic solvent containing a binder, wherein the binder is epoxy resin E-51, the organic solvent is toluene, the mass ratio of toluene to nano-titanium dioxide is 20:1, and the epoxy resin E-51 is The mass ratio of -51 to nano-titanium dioxide is 1:1. After mixing evenly, add curing agent ethylenediamine. The mass ratio of epoxy resin E-51 to ethylenediamine is 8:1. The specific dosage is:

[0034] Toluene: 100g

[0035] Nano titanium dioxide: 5g

[0036] ...

Embodiment 2

[0043] The conditions of the treatment object and catalyst loading method are consistent with those of Example 1, and the operating conditions are: the rotating speed of the turntable is 500r / min, the light source is a 254nm low-pressure mercury lamp, and the light intensity is 13.35mW / cm 2 , the flow rate is 50L / h. Sampling and analysis after 4 hours showed that the removal rate of phenol was 68.12%.

Embodiment 3

[0045] Treatment object and catalyst loading method conditions are consistent with embodiment 1, operating conditions: turntable speed 0r / min, light source is 254nm low-pressure mercury lamp, light intensity 18.45mW / cm 2 , the flow rate is 30L / h. Sampling and analysis after 4 hours showed that the removal rate of phenol was 70.22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com