Energy-saving internal combustion engine

A technology for internal combustion engines and power output shafts, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of occupying car body space, large engine volume, waste, etc., and achieve improved fuel conversion rate, small size, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

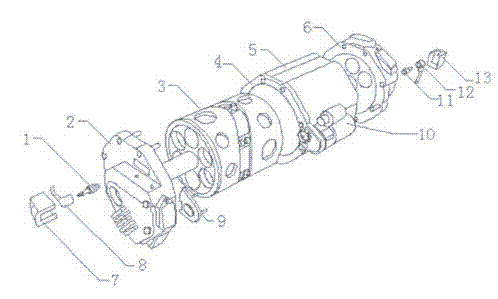

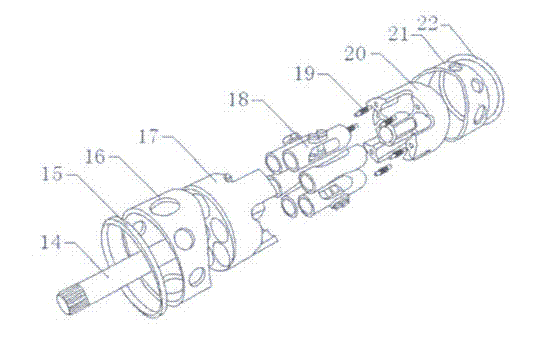

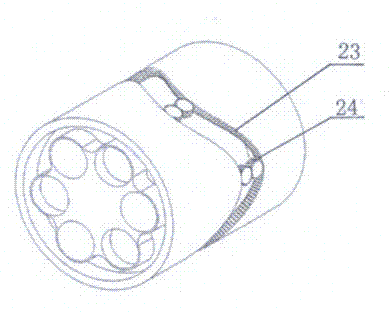

[0021] The cylinder body is cylindrical, and the cylinder body is arranged horizontally. The cylinder body is divided into two parts, the front cylinder body (17) and the rear cylinder body (20) along the axial direction. The front and rear cylinders are connected by expansion pins (19). A tubular stator (16; 21) is set on each of the front and rear cylinders. There are inlet and exhaust ports on the stators. The inner edges of the stators are sinusoidal cam-shaped and uniform. Cloth teeth (23), the inner edges of the two stators form a sinusoidal variable guide groove, and two pin shafts are fixed vertically in the middle of each piston, and gears (24) are installed on each pin shaft through bearings, and the two pin shafts The bearing gear meshes with the teeth in the sinusoidal variable guide groove, and the middle parts of the 6 pistons are connected to form a piston group (18). The front part of the piston moves in the cylinder of the front cylinder body, and the rear part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com