Method for building gypsum block forming production line through control flow modeling and based on Petri network

A technology for controlling process and gypsum blocks, which is applied in the direction of electrical program control and comprehensive factory control, and can solve problems such as complex software and hardware platforms and difficult applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

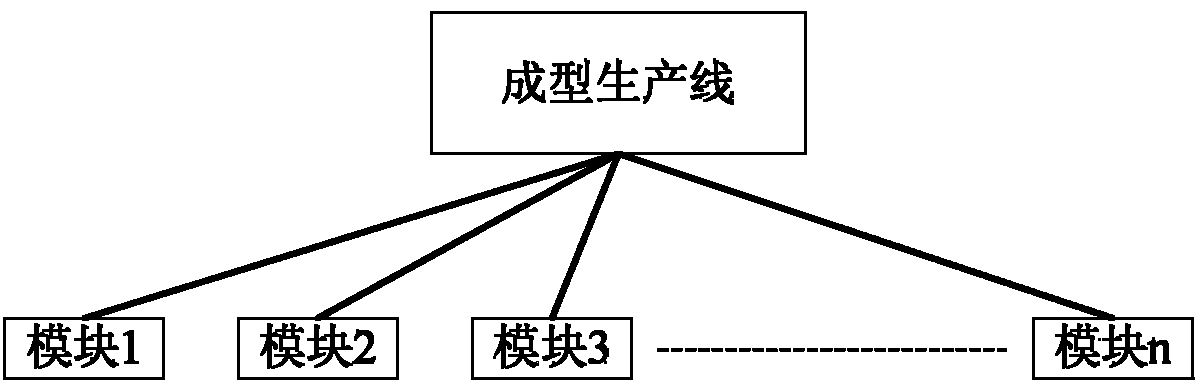

[0062] Step 1: Division of structural and functional modules of the gypsum block forming production line.

[0063] The division of the structural modules of the gypsum block forming production line is based on the principle of the minimum function of the module. According to the principle of gypsum forming and the characteristics of the production line, the production line is divided into several independent functional units. The division of structural and functional modules of a gypsum block forming production line is shown in Table 1.

[0064] Table 1

[0065]

[0066]

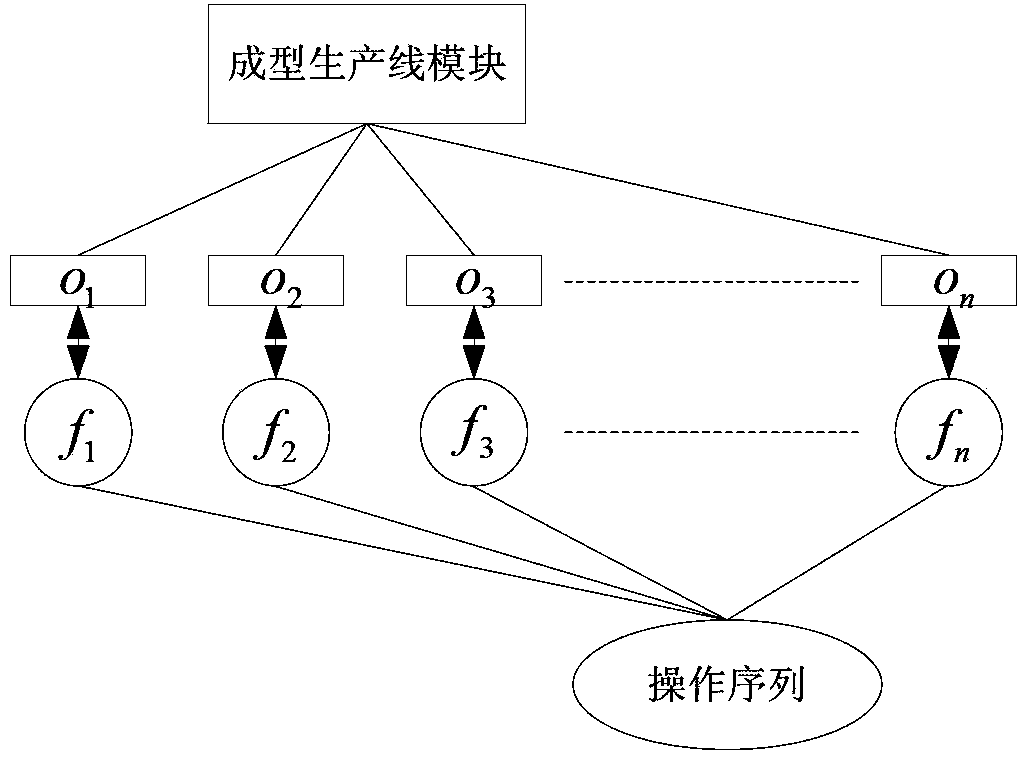

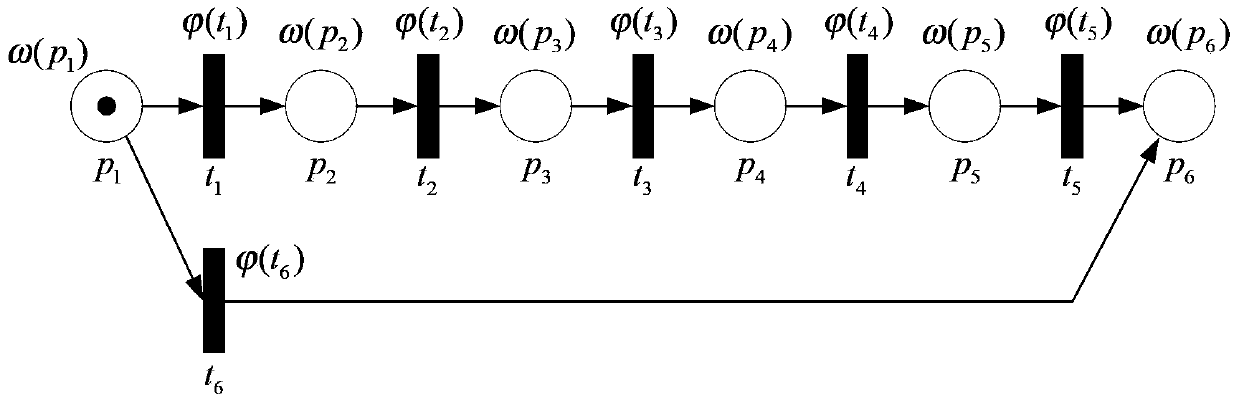

[0067] Step 2: Establish the operation sequence mapping of the functional modules of the production line structure.

[0068] According to the division of the functional modules of the production line structure, a corresponding mapping relationship is established to represent the operation sequence and related auxiliary sequences of the corresponding functional modules in the production process. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com